Description

Key Technical Specifications

- Communication Protocol Support: It covers a variety of mainstream industrial fieldbus protocols, including DeviceNet, Profibus, CANopen, and ControlNet. Users need to customize the corresponding protocol options when purchasing. Among them, the ControlNet protocol is a special case that only supports the slave mode, while other common protocols can switch freely between master and slave modes according to the system communication architecture. This enables the UMAC controller to seamlessly connect with different types of industrial devices that adopt different bus protocols.

- Memory Configuration: The hardware is configured with 32KB SRAM and 128KB flash memory. The SRAM is mainly used for temporary storage of real-time communication data to ensure the continuity and timeliness of data transmission. The flash memory is responsible for storing the firmware required for the operation of the board and protocol-related configuration parameters, which can maintain data stability even when the power is off.

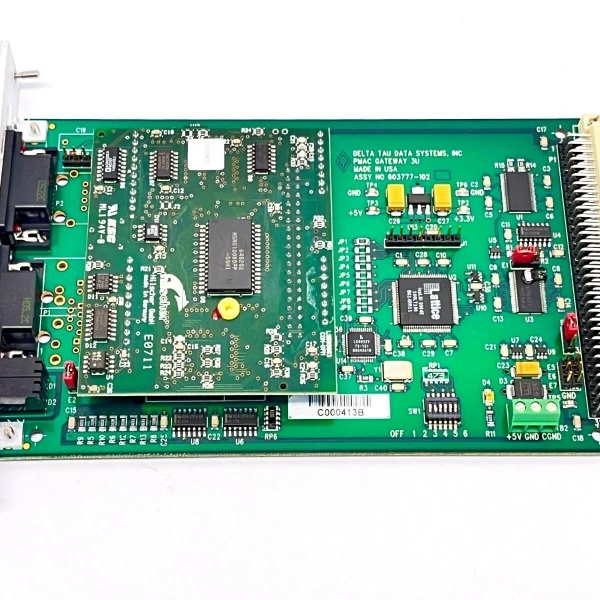

- Hardware Matching & Connection: It is equipped with Hilscher circuit board as the core communication chip to ensure the stability of multi-protocol conversion and data transmission. It is connected to the UMAC controller through a dedicated bus interface, and matches the UMAC system’s bus communication mechanism to realize direct data interaction with the controller without additional adapter modules. At the same time, it supports front-panel configuration (such as CANopen slave option with front panel) to facilitate users’ on-site wiring and debugging.

- Operating Environment & Power Supply: As an industrial-grade product, it can work stably in the temperature range of -10℃ to +50℃, and the storage temperature can reach -20℃ to +70℃, which is adaptable to the temperature fluctuation environment of general industrial workshops. It adopts 24V DC 1A input power supply, and the output supports 0 – 10V DC voltage and 0 – 20mA current, which is compatible with the power supply system of most industrial control cabinets.

ACC-72E

Field Application & Problem Solved

In large-scale industrial automation systems, there are often a large number of devices from different manufacturers, and these devices often adopt different fieldbus protocols, resulting in communication barriers between the UMAC controller and peripheral equipment. This makes it difficult to unify the scheduling of the entire production line and real-time collection of equipment data.

The ACC-72E perfectly solves this problem. It serves as a “protocol translator” for the UMAC system. In semiconductor production lines, it can connect the UMAC controller with multiple process equipment that use Profibus and CANopen protocols respectively, realizing real-time transmission of process parameters such as wafer processing temperature and pressure. In the intelligent workshop of CNC machine tools, it enables the UMAC master controller to uniformly manage multiple CNC machine tools, robotic arms and conveyor belts, and synchronize the production rhythm of each link. In addition, its master-slave dual-mode design is flexible. When acting as a master, it can take the UMAC as the core to control multiple subordinate devices; when acting as a slave, it can integrate the UMAC system into a larger factory-level control network to meet the needs of multi-level management of the factory.

Installation & Maintenance Pitfalls (Expert Tips)

- Ignoring Protocol Option Matching: The board requires customizing the corresponding protocol option when ordering. If the protocol type selected does not match the on-site equipment, it will lead to communication failure. Before purchasing and installing, it is necessary to sort out the bus protocol types of all external devices that need to be connected, and confirm the matching protocol options with the supplier.

- Improper Circuit Board Installation: It is equipped with a Hilscher dedicated circuit board. If the circuit board is not inserted in place during installation or the pin is contaminated, it will cause poor contact. When installing, it is necessary to check the cleanliness of the interface, and ensure that the circuit board is firmly inserted into the slot. After installation, power on and test the communication link immediately.

- Neglecting Power Supply Stability: The board adopts 24V DC input. If the on-site power supply has large fluctuations or voltage ripples, it will interfere with the stability of data transmission, and even cause the board to restart abnormally. It is recommended to configure a dedicated voltage stabilizer or filter for the power supply loop of the board to reduce the impact of power supply interference.

- Ignoring Firmware Compatibility: The communication stability of the board is related to the firmware version of the UMAC controller. If the firmware of the controller is too old, it may not be compatible with the new functions of the board. During maintenance, when updating the controller firmware, it is necessary to check the firmware compatibility information of the ACC-72E, and avoid blind upgrade leading to communication interruption.

ACC-72E

Technical Deep Dive & Overview

The core competitiveness of the ACC-72E lies in its high integration and strong compatibility with the UMAC system. Different from ordinary universal industrial gateways, it is specially customized for the UMAC Turbo system, which can be directly integrated into the system through the dedicated bus, without complex external wiring and protocol debugging, reducing the difficulty of system integration. The Hilscher circuit board it carries is a mature industrial communication chip solution, which ensures the reliability and anti-interference ability of multi-protocol conversion.

Its 32KB SRAM and 128KB flash memory configuration balances real-time performance and data stability. The temporary storage of real-time data by SRAM avoids data loss caused by network delays, while the flash memory’s storage of firmware and configuration parameters ensures that the board can quickly resume work after power-off and restart. In addition, the board can still be supported by suppliers even after the manufacturer stops production, which has strong durability. It is an important supporting component for the long-term stable operation of the UMAC old system and is widely used in the upgrading and transformation of industrial automation systems.