Description

Key Technical & Structural Features

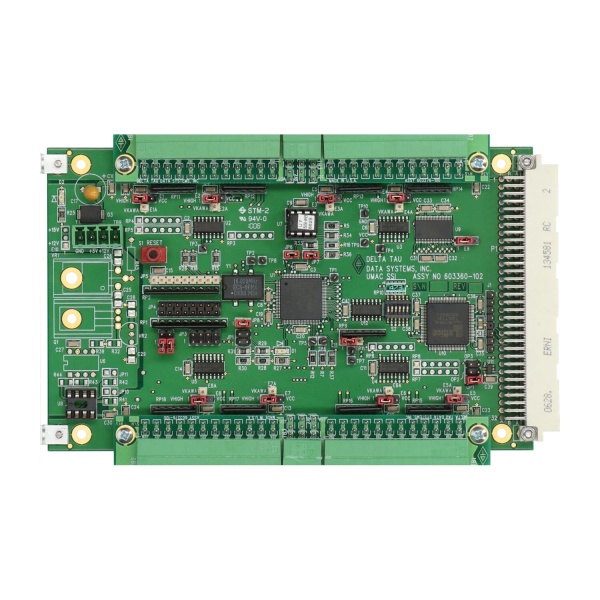

- Core Protocol & Functional Orientation: The board is customized for the SSI protocol. As a common synchronous serial communication protocol in industrial encoders, SSI is known for its high anti-interference ability and stable data transmission. The ACC-53E acts as a “signal bridge” between the SSI encoder and the UMAC controller. It converts the serial position data output by the SSI encoder into a signal format recognizable by the UMAC controller, which ensures the controller can accurately obtain the real-time position information of the mechanical moving parts.

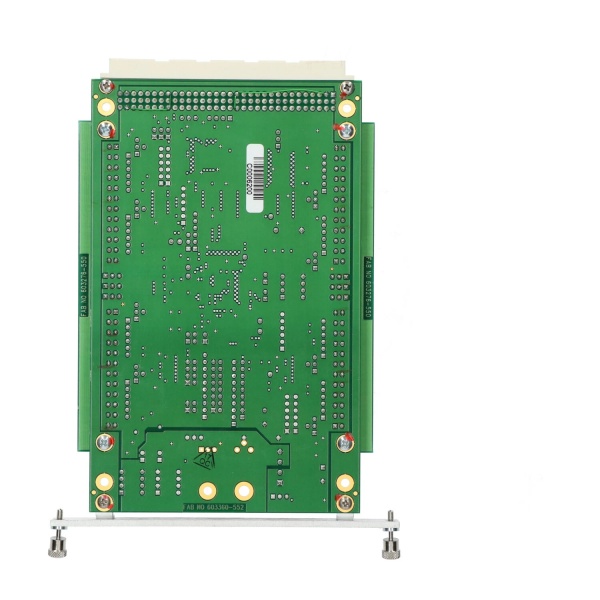

- Hardware Structure Matching: It adopts a 3U Eurocard standard structure, which is perfectly compatible with the 3U rack design of the UMAC modular system. It can be directly slid into the UMAC rack and connected through the UBUS universal bus. This modular design not only simplifies on-site wiring and installation operations but also facilitates quick replacement and maintenance when faults occur. Meanwhile, its weight is only 0.14 kg, which will not increase the burden of the rack system.

- System Compatibility: It has excellent compatibility with DELTA TAU’s UMAC series controllers. It can be seamlessly integrated with various UMAC CPU motherboards, whether it is a general-purpose CPU board for independent operation or a MACRO CPU board with an optical fiber interface. It does not require additional adapter modules, which reduces the complexity of system configuration. In addition, it can work in coordination with other accessory boards of the UMAC system such as the ACC-24E2 series axis boards and ACC-11E I/O boards to form a complete motion control solution.

ACC-53E

Field Application & Problem Solved

In high-precision motion control scenarios, the controller’s accurate acquisition of the real-time position of mechanical components is the key to ensuring the operation accuracy of the equipment. However, the SSI encoder’s output signal cannot be directly recognized by the UMAC controller. If there is a lack of a matching interface board, it will lead to problems such as inability to obtain position data or large data transmission delays, which will seriously affect the equipment’s motion accuracy.

The ACC-53E solves this core problem. In CNC precision machining, it connects the SSI encoder installed on the machine tool’s spindle and feed axis to the UMAC controller, realizing real-time feedback of the tool’s position and movement speed, ensuring the machining accuracy of complex workpieces. In semiconductor wafer production equipment, it can collect the position signals of the wafer transmission mechanism, helping the controller complete the high-precision positioning and transfer of wafers. In robotic arm systems, it transmits the joint position data of the robotic arm to the controller in real time, ensuring the coordination and accuracy of the robotic arm’s multi-axis movement. In addition, its stable signal conversion capability also solves the problem of signal distortion during the transmission process in complex industrial environments, laying a foundation for the stable operation of the equipment.

Installation & Maintenance Pitfalls (Expert Tips)

- Improper Rack Installation: Since it adopts a 3U structure and needs to be installed in the UMAC dedicated rack, if it is not inserted in place during installation or the rack slot is dusty, it will cause poor contact between the board and the bus. Before installation, it is necessary to clean the slot with a dust brush, and after insertion, check whether the board is firmly fixed to avoid poor signal transmission caused by vibration during equipment operation.

- Ignoring Protocol Matching: The board is specially designed for the SSI protocol. If it is mistakenly connected to encoders of other protocols such as incremental encoders, it will result in no data output. Before wiring, it is necessary to confirm that the encoder’s communication protocol is SSI, and check the encoder’s signal pin definition to avoid protocol mismatch problems.

- Neglecting Signal Line Shielding: The SSI encoder signal is easily interfered by the surrounding strong electromagnetic equipment during transmission. If unshielded wires are used for wiring or the signal line is laid parallel to the power line, the collected position data will have errors. It is recommended to use shielded twisted-pair wires for wiring, and keep a safe distance from the power line to enhance anti-interference ability.

- Blind Mixing with Other Feedback Boards: When the UMAC system is configured with multiple feedback interface boards such as ACC-51E and ACC-57E at the same time, if the address configuration is not standardized, signal conflicts may occur. It is necessary to set unique addresses for each feedback board according to the system manual, and verify the signal collection status through the upper computer software to ensure that each board works independently and stably.

ACC-53E

Technical Deep Dive & Overview

The ACC-53E is a cost-effective and targeted encoder interface product in DELTA TAU’s accessory board series. Its core advantage lies in the professional adaptation of the SSI protocol. Compared with universal multi-protocol interface boards, it has higher stability and lower signal delay in SSI signal transmission, which is more in line with the high-precision requirements of motion control systems.

Its integration with the UMAC system’s 3U modular architecture also reflects strong practicality. It can be flexibly combined with other functional boards of the UMAC system to meet the personalized configuration needs of different motion control projects. In the after-sales and maintenance aspects, the board has a simple structure and few fault points. It is a key component to ensure the position control accuracy of the UMAC system, and is irreplaceable in many precision manufacturing fields that rely on SSI encoder feedback.