Description

Key Technical Specifications

- Channel Configuration: The standard configuration provides 2 channels, and can be expanded to 4 channels by adding the Option 1 sub – module. When the expansion sub – module is installed, it occupies 2 slots of the 3U rack. A single UMAC controller can be connected to up to 8 ACC – 24E2A boards, which can expand the servo interface circuit to 32 channels at most.

- Control Signal Support: It supports a variety of servo and stepper control interfaces, including ±10V analog velocity commands, ±10V analog torque commands, sinusoidal analog phase current commands, as well as pulse and direction commands, which are compatible with most servo drives and stepper systems on the market.

- Encoder Interface: Each channel is equipped with a 3 – channel differential/single – ended encoder input interface, which can be configured through a resistor pack. It is compatible with incremental encoders and some grating encoders, and has an encoder loss detection circuit to timely feedback the encoder signal status.

- I/O and Auxiliary Functions: Each axis is equipped with 8 universal digital input flags and 2 universal digital output flags, supporting 5V – 24V flag input voltage levels. It also has amplifier fault and enable circuits to improve the safety and stability of the control system.

- Installation and Power Supply: It adopts 3U rack – mounted insertion design and is installed in the UMAC main frame. The power supply is ±15V DC, which is supplied by the host backplane without additional independent power supply.

- Operating Environment: The working temperature range is 0°C – 60°C, and it complies with industrial anti-interference specifications, which can stably operate in general industrial workshops and laboratory environments.

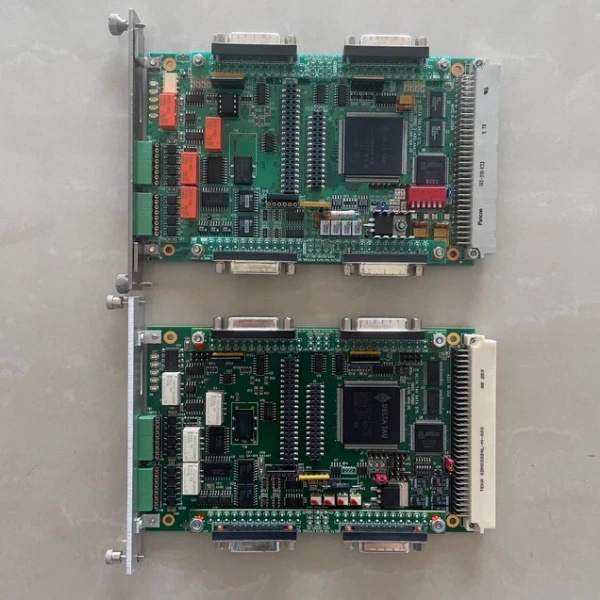

ACC-24E2A

Field Application & Problem Solved

In high-precision industrial control fields such as semiconductor manufacturing, precision machining, and robotic operations, the number of axes of the original controller is often insufficient to meet the control needs of multi – station and multi – execution components. For example, when a CNC machine tool needs to add additional spindle or feed axes, or when a multi – axis robotic arm needs to expand the end – effector control axis, it is not cost-effective to replace the entire high – cost main controller. At the same time, these scenarios also require the expansion module to have high synchronization with the original system and high control precision.

The ACC – 24E2A solves these pain points well. It can be directly plugged into the UMAC and other controllers through the expansion port, and can be flexibly expanded from 2 to 4 axes. It also supports multiple control modes to match different types of servo and stepper motors. In semiconductor wafer processing equipment, it can expand the control channels of the UMAC controller to realize the synchronous control of multiple wafer transfer and processing axes; in multi – axis laser cutting machines, it can ensure the high-precision matching between the laser head movement axis and the workbench movement axis. In addition, its encoder loss detection function can timely alarm when the encoder signal is abnormal, avoiding product scrap or equipment damage caused by signal loss, which is crucial for scenarios with high processing accuracy requirements.

Installation & Maintenance Pitfalls (Expert Tips)

- Incorrect Matching of Expansion Quantity and CPU: The number of expandable ACC – 24E2A boards is limited by the main controller’s CPU. The 16 – axis Macro CPU can only support 4 such expansion boards, and the 8 – axis Macro CPU can only support 2. If the number of expansion boards exceeds the limit, the system will fail to recognize or work abnormally. It is necessary to confirm the CPU model of the main controller before installation and plan the expansion quantity reasonably.

- Encoder Signal Type Configuration Error: The board supports both differential and single – ended encoders, which need to be selected through resistor pack configuration during installation. Many users ignore this step and directly wire, resulting in encoder signal distortion or no signal. It is necessary to select the corresponding resistor pack according to the encoder type used and complete the hardware configuration.

- Neglecting Flag Input Voltage Matching: The board’s flag input supports 5V – 24V voltage. If the input voltage does not match the resistor pack configuration of the limit/flag voltage level, it will lead to false triggering of the input signal or failure to trigger. During maintenance, the voltage level of the connected signal should be checked first when there is an input abnormality.

- Improper Installation of Expansion Sub – module: When expanding from 2 axes to 4 axes by adding the Option 1 sub – module, if the sub – module is not inserted in place or the slot is wrong, it will cause the expansion channel to fail to work. It should be ensured that the sub – module is firmly inserted into the specified interface, and after installation, the channel status should be detected through the upper software.

ACC-24E2A

Technical Deep Dive & Overview

The core advantage of the ACC – 24E2A lies in its high integration and strong compatibility with the DELTA TAU control system. It integrates a 4 – channel PMAC2 – style servo integrated circuit, which can realize independent servo loop control. It supports PID adjustment and feed – forward control algorithms, ensuring the high precision and fast response of the control process. Unlike independent motion control modules, it does not have an independent processor and relies on the main controller for instruction processing, which can avoid synchronization errors between the expansion module and the main system.

The design of its multi – type control interface reflects strong flexibility. The ±10V analog control mode is suitable for traditional servo drives, while the pulse – direction mode can match stepper systems, enabling users to choose different types of execution components according to application needs. The newly added encoder loss detection circuit is a major highlight. It can timely feed back the encoder fault to the main controller, and the main controller can quickly trigger protective actions such as emergency stop, which greatly improves the reliability of the system.

As an important part of DELTA TAU’s motion control solution, although it is an expansion board, it is highly integrated with the Power PMAC programming language of the main controller. Users can uniformly configure and debug the expansion channel through the upper software, without writing independent control programs for the module, which reduces the difficulty of system development. At present, even though there are more new motion control modules on the market, it is still widely used in the transformation and upgrading of legacy UMAC systems due to its stable performance and high cost – effectiveness, and is an important supporting component in many high-precision industrial automation fields.