Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Bently Nevada 79492-01 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Category | Seismic Velocity Sensor |

| Measurement Range | 0.5 to 1000 Hz frequency |

| Sensitivity | 100 mV/in/s (±5%) |

| Frequency Response | 4.5 Hz to 10 kHz (±3dB) |

| Dynamic Range | >80 dB |

| Operating Temperature | -50°C to +120°C |

| Housing Material | 316 Stainless Steel |

| Connector Type | MIL-C-5015 threaded |

| Mounting | 1/4-28 UNF threaded stud |

| Weight | 0.45 kg (1 lb) |

| Certifications | ATEX, IECEx, CSA, CE |

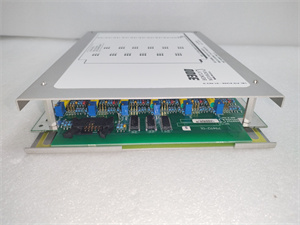

BENTLY 79492-01

Product Introduction

The Bently Nevada 79492-01 is a rugged seismic velocity sensor designed for permanent machinery monitoring in extreme industrial environments. Part of Bently Nevada’s comprehensive condition monitoring portfolio, this sensor provides reliable velocity-based vibration measurements for predictive maintenance of turbines, compressors, and other critical rotating equipment.

Engineered for continuous operation, the 79492-01 features a hermetically sealed stainless steel housing that withstands harsh conditions including moisture, chemicals, and explosive atmospheres. Its broad frequency response (4.5 Hz to 10 kHz) captures both low-speed machinery dynamics and high-frequency bearing defects, making it invaluable for comprehensive asset health monitoring.

Core Advantages and Technical Highlights

Precision vibration measurement:

The Bently Nevada 79492-01 delivers 100 mV/in/s sensitivity with ±5% tolerance for consistent velocity measurements across its operating range. The 4.5 Hz low-frequency cutoff enables accurate monitoring of slow-speed machinery, while the 10 kHz upper range detects early-stage bearing and gear mesh faults.

Extreme environment durability:

Constructed with 316 stainless steel, the sensor resists corrosion in offshore, refinery, and chemical plant environments. Its hermetic sealing (IP68 equivalent) prevents moisture ingress, and the -50°C to +120°C operating range ensures performance in arctic cold or desert heat conditions.

Reliable signal integrity:

The 79492-01 incorporates electromagnetic shielding that maintains signal quality in electrically noisy environments. The MIL-C-5015 threaded connector provides secure, vibration-resistant electrical connections, while integral cable strain relief prevents conductor fatigue.

Safety certifications:

Certified for ATEX Zone 0/20 and IECEx hazardous areas, the sensor meets global requirements for oil/gas, mining, and chemical applications. CSA and CE markings ensure compliance with North American and European standards.

Typical Application Scenarios

Gas turbine monitoring:

The Bently Nevada 79492-01 provides casing vibration data for aeroderivative turbines, detecting blade passing frequencies and combustion dynamics. Its wide temperature range allows installation near hot gas paths.

Offshore compressor packages:

Mounted on reciprocating compressors, the sensor’s hazardous area certification enables vibration monitoring in classified zones. The stainless steel construction withstands salt spray corrosion.

Power plant steam turbines:

Monitoring bearing housing vibration, the 79492-01 helps detect misalignment and fluid-induced instabilities. The broad frequency response captures both low-speed rotor dynamics and high-frequency steam whirl.

Mining conveyor systems:

The sensor’s rugged design survives the dust and vibration of mineral processing, providing early warning of gearbox and roller bearing failures through velocity trend analysis.

BENTLY 79492-01

Related Model Recommendations

Bently Nevada 79445-01: Accelerometer for higher frequency measurements

Bently Nevada 3300/25: Proximity transducer for shaft relative vibration

Bently Nevada 3500/42M: Vibration monitor for system integration

Bently Nevada 1900/65A: Portable vibration analyzer

Bently Nevada 3300/16: Proximitor® sensor power supply

Bently Nevada 3500/22M: Transient Data Interface Module

Installation and Commissioning

Installation preparation:

Select a mounting location on the machine casing that provides direct vibration transmission. Clean the surface thoroughly and verify the 1/4-28 UNF mounting stud is perpendicular to the surface. Route cables away from high-voltage sources and moving parts.

Commissioning steps:

Securely mount the sensor using the provided hardware

Verify proper grounding of the monitoring system

Check baseline vibration levels at normal operating conditions

Set alarm thresholds in the monitoring software

Document initial readings for future reference

Verify signal quality across the full speed range

Maintenance recommendations:

Quarterly inspections should verify connector integrity and cable condition. Annual calibration checks against reference standards are recommended. Monitor trending data for sensitivity changes indicating potential sensor degradation. Keep spare sensors for critical equipment, stored in their original packaging.

Service and Guarantee Commitment

Baker Hughes provides a 24-month warranty for the Bently Nevada 79492-01, supported by:

Global network of vibration experts

24/7 technical support hotline

On-site calibration services

Repair and recalibration programs

Comprehensive training courses

The sensor is backed by Bently Nevada’s Machine Health Center with remote diagnostics support and lifetime access to firmware updates. All units ship with complete documentation including calibration certificates and hazardous area certifications.