Description

Detailed parameter table

| Parameter name | Parameter value |

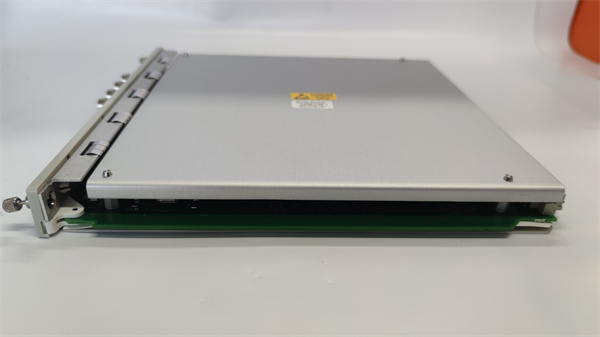

| Product model | 3500/40 176449-01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Transducer signal conditioner module |

| Electrical performance | 24V DC power supply; Power consumption: 7W max; Input range: ±10V DC, 4-20mA |

| Physical size | Width: 24.4mm, Height: 241.3mm, Depth: 242mm |

| Interface type | Backplane connector for 3500 series rack communication; 4 analog input channels; 4 analog output channels (4-20mA) |

| Signal processing | 16-bit ADC resolution; Filtering options: 1Hz, 10Hz, 100Hz, 1kHz; Isolation: 2.5kVrms channel-to-channel |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95%, non-condensing; Vibration resistance: 10g peak (10-2000Hz) |

| Installation method | Rack-mountable in 3500 series racks; Occupies 1 standard slot |

| Compatibility | Compatible with all 3500 series modules, including 3500/60 163179-01, 3500/50 133388-02, 3500/05-01-02-00-00-01, etc. |

BENTLY 3500/40 176449-01

Product introduction

The BENTLY NEVADA 3500/40 176449-01 is a versatile transducer signal conditioner module, designed to bridge external sensors and the 3500 series machinery protection system. It specializes in conditioning, filtering, and converting raw analog signals from a wide range of industrial sensors—such as temperature probes, pressure transducers, and load cells—into standardized outputs compatible with 3500 series modules like the 3500/60 163179-01 relay module and 3500/05-01-02-00-00-01 rack interface.

This module acts as a critical intermediary, ensuring that non-native sensor signals (those not directly compatible with 3500 series input requirements) are accurately processed and integrated into the system. With 4 input channels and 4 corresponding output channels, it can handle multiple sensor types simultaneously, making it ideal for expanding the monitoring capabilities of 3500 series racks beyond vibration and rotational speed. By converting signals to the 4-20mA standard, it enables seamless integration with alarm systems, data loggers, and control devices—including the 3500/60 163179-01, which can trigger relays based on conditioned signals.

Core advantages and technical highlights

Multi-sensor compatibility: The 3500/40 176449-01 supports a broad range of input types, including ±10V DC and 4-20mA signals, making it compatible with temperature sensors (e.g., RTDs via transmitters), pressure transducers, flow meters, and level sensors. This flexibility allows 3500 series systems to monitor auxiliary machinery parameters alongside vibration and speed data from modules like the 3500/25 149369-01 and 3500/33 149986-01.

Precision signal conditioning: Equipped with 16-bit ADC resolution and selectable filtering (1Hz to 1kHz), the module ensures accurate signal conversion and noise reduction. For example, it can filter high-frequency noise from a pressure transducer’s output before transmitting the signal to the 3500/60 163179-01 relay module, preventing false alarms caused by electrical interference.

Channel isolation: Each input channel features 2.5kVrms isolation from other channels and the backplane, protecting the 3500 series rack from ground loops, voltage spikes, and cross-talk. This isolation is critical when integrating sensors from different parts of a facility, where electrical potentials may vary—ensuring measurement integrity and system safety.

Seamless integration with alarm systems: The module’s 4-20mA outputs can be directly connected to the 3500/60 163179-01 relay module, enabling alarm triggers based on conditioned signals. For example, a high-temperature signal from a bearing thermocouple (conditioned by the 3500/40 176449-01) can activate a relay in the 3500/60 163179-01 to trigger a cooling system or shutdown, creating a closed-loop control chain.

Typical application scenarios

In gas turbine power plants, the 3500/40 176449-01 is used to integrate auxiliary sensors into the 3500 series system. It conditions signals from exhaust gas temperature probes (converting thermocouple mV outputs to 4-20mA) and fuel pressure transducers, then sends these signals to the 3500/05-01-02-00-00-01 rack interface. If temperature exceeds a threshold, the 3500/60 163179-01 relay module—receiving the conditioned signal—activates a relay to reduce fuel flow, preventing turbine damage. The 3500/50 133388-02 display shows both the raw and conditioned temperature values for operator verification.

Within refinery pump stations, the module processes signals from vibration accelerometers (non-native to 3500 series) and bearing temperature sensors. It filters vibration data to remove pump cavitation noise and converts temperature signals to 4-20mA, which are then used by the 3500/60 163179-01 to trigger alarms: a first-level alert for elevated temperature and a shutdown relay if vibration exceeds safe limits. This integration ensures that all critical pump parameters are monitored within a single system.

In manufacturing facilities with hydraulic presses, the 3500/40 176449-01 conditions pressure transducer signals from hydraulic lines and load cell outputs from press dies. It converts these signals to standardized outputs, which are fed to both the 3500/50 133388-02 display (for operator monitoring) and the 3500/60 163179-01 relay module. If pressure drops unexpectedly (indicating a leak), the relay module activates a shutdown, preventing workpiece damage.

Relationship with 3500/60 163179-01 and other modules

The 3500/40 176449-01 enhances the functionality of the 3500/60 163179-01 relay module and other 3500 series components by expanding their input capabilities:

With 3500/60 163179-01: The signal conditioner provides conditioned, standardized signals that the relay module uses to trigger alarms and control actions. For example, a temperature signal from the 3500/40 176449-01 can be mapped to a relay in the 3500/60 163179-01, enabling temperature-based shutdowns or alerts.

With 3500/05-01-02-00-00-01: The rack interface module aggregates data from the 3500/40 176449-01 alongside other modules (e.g., 3500/25 149369-01), ensuring that all sensor data is synchronized and available to the system. This aggregated data is used to generate comprehensive alarms for the 3500/60 163179-01.

With 3500/50 133388-02: The display module shows real-time values of conditioned signals from the 3500/40 176449-01, allowing operators to monitor parameters like temperature, pressure, or flow alongside vibration and speed data. This unified view enhances situational awareness.

With 170190-01E software: The software configures the 3500/40 176449-01’s filtering, scaling, and alarm thresholds, then uses the conditioned data for trend analysis and reporting. It can also link these parameters to the 3500/60 163179-01’s relay settings for coordinated system configuration.

Related model recommendations

3500/40 176449-02: A variant with 8 input/output channels, suitable for systems requiring more sensor integrations.

3500/60 163179-01: Relay module that uses conditioned signals from the 3500/40 176449-01 to trigger control actions.

3500/50 133388-02: Display module that visualizes conditioned data from the 3500/40 176449-01.

3500/05-01-02-00-00-01: Rack interface module that aggregates data from the 3500/40 176449-01 for system-wide distribution.

330103-00-05-10-02-00: Keyphasor sensor whose signal, while native to 3500/25 149369-01, can be routed through the 3500/40 176449-01 for additional filtering.

149992-01: Shielded cable for connecting external sensors to the 3500/40 176449-01, minimizing noise interference.

3500/15 106M1079-01: Power supply module ensuring stable operation of the 3500/40 176449-01.

Installation, commissioning and maintenance instructions

Installation preparation: Install the 3500/40 176449-01 in an available slot in the 3500 rack. Power off the rack and use an anti-static wrist strap. Ensure the module is positioned to facilitate wiring from external sensors (e.g., temperature probes, pressure transducers). Required tools include a torque wrench (0.5-0.7Nm), wire strippers, and a screwdriver for terminal blocks.

Installation steps: Align the module with rack guides and insert until the backplane connector engages. Secure with mounting screws. Connect external sensors to the input channels—use shielded cables (e.g., 149992-01) to reduce noise. Wire the output channels to downstream devices, such as the 3500/60 163179-01 relay module or data loggers. Label all connections clearly to avoid misconfiguration.

Commissioning: Power on the rack and launch 170190-01E software to configure the module. For each channel, set input type (±10V or 4-20mA), scaling (e.g., convert 4-20mA to temperature in °C), and filtering (based on sensor type). Calibrate inputs using a signal generator to ensure accurate conversion. Test signal flow by applying a known input and verifying the output on the 3500/50 133388-02 display and 3500/60 163179-01 relay activation (if configured).

Maintenance suggestions: Perform monthly visual inspections to check for loose connections, terminal corrosion, or damaged cables. Clean terminals with a dry cloth and tighten connections as needed. Quarterly, verify calibration using a precision signal generator and adjust via 170190-01E if drift is detected. Test channel isolation with a megohmmeter to ensure it remains above 2.5kVrms. Backup configurations via the software to streamline recovery in case of module replacement.

Service and guarantee commitment

The 3500/40 176449-01 comes with a 12-month warranty covering manufacturing defects, including signal conversion errors, channel isolation failures, or backplane issues. During this period, we provide free repair/replacement and 24/7 technical support for configuration with the 3500/60 163179-01 and other modules.

Optional extended warranties (up to 3 years) include priority support, on-site calibration, and replacement of worn components. Backed by BENTLY NEVADA’s expertise in signal processing, the 3500/40 176449-01 is guaranteed to deliver accurate, reliable signal conditioning, expanding the versatility of your 3500 series system to monitor a wider range of machinery parameters.