Description

Detailed parameter table

| Parameter name | Parameter value |

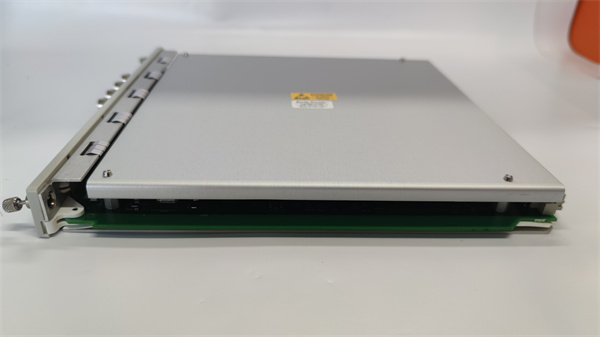

| Product model | 3500/40 176449 – 01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Proximity monitor |

| Electrical performance | 24V DC power supply, typical power consumption 7.7W; 4 – 20mA and 0 – 10V DC outputs |

| Physical size | 102mm (width) × 152mm (height) × 203mm (depth) |

| Interface type | Accepts 1 – 4 BENTLY NEVADA proximity sensor inputs; relay contacts for alarm outputs |

| Communication protocol | Modbus RTU/TCP, Ethernet |

| Environmental requirements | Operating temperature: – 40°C to 85°C; Humidity: 5% – 95%, non – condensing |

| Installation method | Rack – mountable, compatible with 3500 series racks |

| Performance indicators | Sensitivity: 7.87V/mm (200mV/mil); Linear measurement range: 0 – 2mm; Compliant with API 670 standard |

BENTLY 3500/40 176449-01

Product introduction

The BENTLY NEVADA 3500/40 176449 – 01 is a high – precision proximity monitor that is a key component of the BENTLY NEVADA 3500 machinery protection system. It is specifically designed to continuously and accurately monitor vibration and position parameters of rotating machinery, providing critical data for ensuring the safe and efficient operation of industrial equipment.

As an essential part of the 3500 series, the BENTLY NEVADA 3500/40 176449 – 01 integrates advanced signal processing technology to convert sensor inputs into meaningful measurements such as radial vibration, shaft eccentricity, and thrust position. Its role in automation systems is indispensable, as it enables early detection of potential mechanical faults, allowing for timely maintenance and reducing the risk of unplanned downtime.

Core advantages and technical highlights

High – precision measurement: The 3500/40 176449 – 01 utilizes advanced eddy current technology to achieve exceptional measurement accuracy. With a sensitivity of 7.87V/mm (200mV/mil) and a linear range of 0 – 2mm, it can detect even the smallest changes in machinery vibration and position, ensuring that subtle faults are not missed. This level of precision is crucial for protecting high – value rotating equipment where minor issues can escalate into major failures.

Wide environmental adaptability: Operating within a temperature range of – 40°C to 85°C and capable of withstanding humidity levels from 5% to 95% (non – condensing), the 3500/40 176449 – 01 is well – suited for harsh industrial environments. Whether in the high – temperature surroundings of a steel mill or the cold conditions of a northern power plant, it maintains stable performance, providing reliable monitoring data at all times.

Strong reliability: The 3500/40 176449 – 01 features a dual – redundant power supply design, ensuring continuous operation even if one power source fails. It also supports hot – swapping, allowing for module replacement without shutting down the entire system, minimizing maintenance – related downtime. Additionally, its IP20 protection rating effectively prevents dust ingress, safeguarding internal components and extending the product’s service life.

Seamless integration: Supporting Modbus RTU/TCP and Ethernet protocols, the 3500/40 176449 – 01 can easily integrate with distributed control systems (DCS) and monitoring networks. This enables smooth data transmission between the monitor and central control systems, facilitating centralized management and analysis of machinery health data, and enhancing the overall efficiency of industrial automation systems.

Typical application scenarios

In the power generation industry, the 3500/40 176449 – 01 is widely used for monitoring steam turbines and generators. For steam turbines, it tracks radial vibration and shaft displacement, helping detect problems such as rotor imbalance and misalignment at an early stage. By providing real – time data, it allows operators to take corrective actions before these issues lead to turbine damage or unplanned shutdowns, ensuring a stable power supply.

In the petrochemical sector, the 3500/40 176449 – 01 plays a vital role in monitoring compressors and pumps. It continuously measures the vibration of compressors, enabling the early detection of bearing wear and blade damage. For pumps, it monitors vibration and position to identify cavitation and impeller wear, ensuring the smooth transportation of raw materials and products, and maintaining the integrity of the production process.

In manufacturing, the 3500/40 176449 – 01 is used to monitor large motors and fans. It keeps track of motor vibration to detect rotor imbalance and bearing faults, preventing unexpected motor failures that could disrupt production lines. For fans, it monitors vibration to ensure proper operation, maintaining good ventilation in production workshops and ensuring a safe working environment.

BENTLY 3500/40 176449-01

Related model recommendations

3500/15: A power supply module from the same 3500 series, it provides stable power to the 3500/40 176449 – 01 and other modules in the system, ensuring their reliable operation.

3500/20: A rack interface module that facilitates communication between the 3500/40 176449 – 01 and the 3500 rack, enabling data exchange within the system.

3500/33: A vibration monitor similar to the 3500/40 176449 – 01 but with a focus on specific vibration measurement parameters, often used in conjunction for comprehensive machinery monitoring.

3500/92: A communication gateway module that enhances the data transmission capabilities of the 3500/40 176449 – 01, allowing it to connect with more types of external systems.

330180 – 90 – 00: A proximity sensor compatible with the 3500/40 176449 – 01, providing accurate input signals for vibration and position measurement.

3500/42: An upgraded version of the 3500/40 176449 – 01 with enhanced processing power and additional measurement functions, suitable for more complex monitoring requirements.

3500/50: A display module that works with the 3500/40 176449 – 01 to visually present monitoring data, making it easier for operators to understand machinery status.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 3500/40 176449 – 01, ensure the installation environment is clean and free from dust and moisture. Check that the 3500 rack is properly grounded and has sufficient space for the module. Required tools include a screwdriver and torque wrench. Power off the system before installation to avoid electrical hazards. Carefully align the module with the rack slots to prevent damage to the connectors.

Maintenance suggestions: Regularly inspect the 3500/40 176449 – 01 for physical damage and ensure all connections are tight. Clean the module’s surface with a dry cloth to remove dust. Calibrate the monitor periodically using standard calibration tools to maintain measurement accuracy. If an alarm is triggered, first check the sensor connections and power supply. For component replacement, use genuine BENTLY NEVADA spare parts to ensure compatibility and performance. Keep a maintenance log to track the module’s operation and service history.

Service and guarantee commitment

The 3500/40 176449 – 01 comes with a 12 – month warranty from the date of purchase. During the warranty period, we will provide free repair or replacement for any defects caused by manufacturing issues. Our professional technical support team is available 24/7 to assist with installation, commissioning, and troubleshooting. We offer online technical guidance, phone consultations, and on – site support if needed. We are committed to ensuring the reliable operation of the 3500/40 176449 – 01 and providing customers with peace of mind through our comprehensive after – sales service. Our confidence in the product’s quality is backed by our dedication to customer satisfaction and long – term partnership.