Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

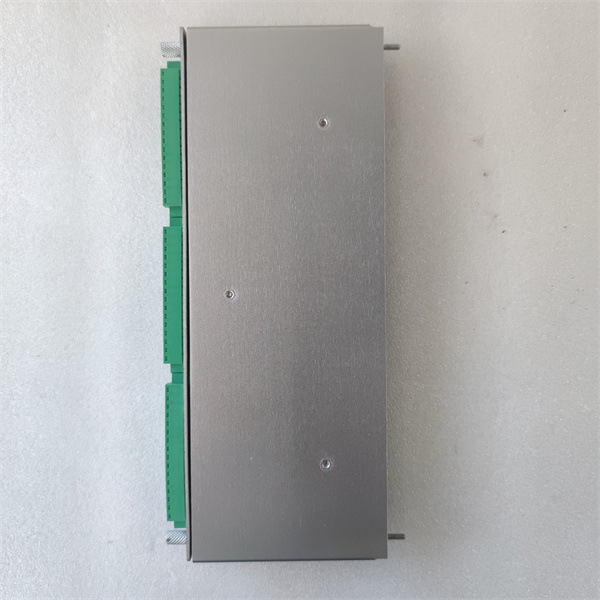

| Product Model | Bently Nevada 3500/33 149992-01 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Category | Speed Monitoring Module |

| Input Channels | 2 independent |

| Speed Range | 1 to 99,999 RPM |

| Accuracy | ±1 RPM or 0.01% (whichever is greater) |

| Input Types | Magnetic pickup, proximity probe, optical encoder |

| Alarm Relays | 4 per channel (Danger, Alert, etc.) |

| Response Time | <100 ms for speed changes |

| Power Supply | 18-30V DC or 90-250V AC |

| Operating Temperature | -20°C to +65°C |

| Dimensions | 3U (133.4 mm) rack height |

| Certifications | ATEX, IECEx, SIL 2 |

BENTLY 3500/33 149992-01

Product Introduction

The Bently Nevada 3500/33 149992-01 is a high-performance speed monitoring module for the 3500 Machinery Protection System. This critical component provides reliable overspeed and underspeed protection for turbines, compressors, and other rotating equipment where precise speed monitoring is essential for safety and equipment protection.

Designed for mission-critical applications, the 3500/33 module offers dual-channel redundancy and meets SIL 2 safety requirements. Its flexible input configuration supports various speed sensors including magnetic pickups, proximity probes, and optical encoders, making it suitable for virtually any industrial rotating machinery application.

Core Advantages and Technical Highlights

Precision Speed Monitoring:

1 to 99,999 RPM range covers all industrial machinery

±1 RPM or 0.01% accuracy for precise speed control

<100 ms response time for rapid overspeed detection

Programmable overspeed/underspeed curves

Advanced Protection Features:

Dual-channel voting logic for fail-safe operation

4 configurable alarms per channel (Danger, Alert, etc.)

Built-in sensor diagnostics for fault detection

SIL 2 compliant safety architecture

Flexible Configuration:

Multiple sensor input types supported

Programmable filter settings for noisy environments

Scalable voting logic for redundancy requirements

Event capture buffer for transient analysis

Industrial Reliability:

-20°C to +65°C operating range

Vibration-resistant design

Hot-swappable in redundant configurations

Long-term calibration stability

Typical Application Scenarios

Power Generation:

Steam turbine overspeed protection

Gas turbine startup sequencing

Generator speed synchronization

Oil & Gas:

Compressor train speed monitoring

Pipeline pump overspeed protection

Offshore platform critical machinery

Industrial Plants:

Large motor speed verification

Process compressor protection

Critical fan speed monitoring

Marine Applications:

Main propulsion engine monitoring

Shipboard turbine overspeed protection

Auxiliary machinery speed control

BENTLY 3500/33 149992-01

Related Model Recommendations

Bently Nevada 3500/33M: Enhanced version with metering

Bently Nevada 3500/42M: Vibration monitoring module

Bently Nevada 3500/25: Proximity probe monitor

Bently Nevada 3500/22M: Transient data module

Bently Nevada 3500/15: Power supply module

Bently Nevada 3300 XL: Alternative monitoring system

Installation and Commissioning

Installation Preparation:

Verify proper rack space in 3500 chassis

Prepare sensor cables per specifications

Ensure proper grounding of system

Have configuration tools ready

Commissioning Steps:

Install module in designated slot

Configure sensor input parameters

Set speed alarm thresholds

Test voting logic (if used)

Verify response to speed changes

Document all settings

Maintenance Recommendations:

Annual calibration verification

Regular inspection of connections

Firmware updates during outages

Monitoring of diagnostic status

Spare module for critical applications

Service and Guarantee Commitment

Baker Hughes provides:

36-month warranty

Global technical support

On-site commissioning

Firmware updates

Repair services

The Bently Nevada 3500/33 149992-01 is backed by Baker Hughes’ Machine Health Center with 24/7 support. All modules include complete documentation and meet global safety standards for machinery protection applications.