Description

Detailed parameter table

| Parameter name | Parameter value |

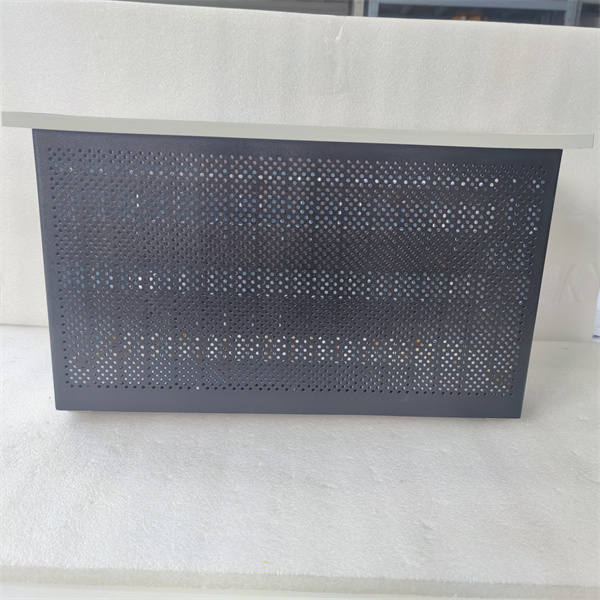

| Product model | 3500/05-01-02-00-00-01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Rack interface module |

| Electrical performance | 24V DC power supply; Power consumption: 4.5W max; Communication bus: 3500 system backplane |

| Physical size | Width: 24.4mm, Height: 241.3mm, Depth: 242mm |

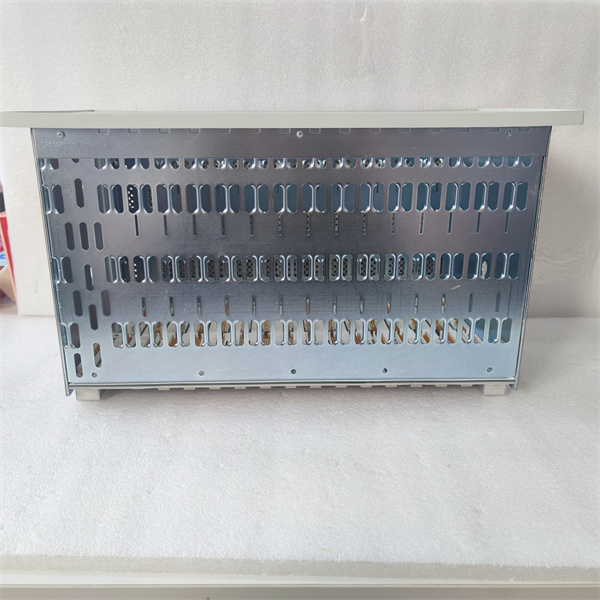

| Interface type | Backplane connector for internal system communication; RS-232 port for local configuration; Ethernet port (10/100Base-T) for network connectivity |

| Communication protocol | Supports 3500 series proprietary protocol; Modbus TCP/IP over Ethernet; Compatible with system configuration software |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95%, non-condensing; Vibration resistance: 10g peak (10-2000Hz) |

| Installation method | Rack-mountable in 3500 series racks; Required as the first module in the rack (leftmost position) |

| Performance indicators | Data transfer rate: Up to 100Mbps over Ethernet; Supports up to 16 modules per rack; Configuration storage: Non-volatile memory |

BENTLY 3500/05-01-02-00-00-01

Product introduction

The BENTLY NEVADA 3500/05-01-02-00-00-01 is a critical rack interface module, serving as the central communication and control hub for 3500 series machinery protection systems. It acts as the backbone of the rack, facilitating data exchange between all installed modules—such as the 3500/25 149369-01 Keyphasor monitor, vibration monitors, and power supplies—and external systems like DCS, SCADA, or configuration software.

This module is responsible for coordinating system operations, including configuration management, alarm aggregation, and data routing. It stores the rack configuration in non-volatile memory, ensuring that settings are preserved even during power cycles. With both local (RS-232) and network (Ethernet) connectivity, the 3500/05-01-02-00-00-01 enables flexible system setup and monitoring, making it an indispensable component for integrating 3500 series modules into broader industrial automation networks.

Core advantages and technical highlights

Centralized system coordination: The 3500/05-01-02-00-00-01 serves as the nerve center of the 3500 rack, managing communication between all connected modules. It synchronizes data collection from modules like the 3500/25 149369-01 (Keyphasor monitor) and vibration monitors, ensuring time-aligned measurements critical for accurate machinery diagnostics. This centralized coordination eliminates data latency issues that could compromise the correlation of vibration, speed, and position data.

Dual communication interfaces: Equipped with both RS-232 for local configuration and 10/100Base-T Ethernet for network integration, the module offers versatile connectivity options. The Ethernet port supports Modbus TCP/IP, enabling seamless integration with plant-wide control systems, while the RS-232 port allows direct connection to laptops or local HMIs for on-site configuration. This duality ensures flexibility in both initial setup and ongoing system management.

Robust configuration management: The module stores rack configurations in non-volatile memory, protecting against data loss during power outages. It supports remote configuration updates via Ethernet, allowing engineers to modify settings for multiple modules—including sensor parameters, alarm thresholds, and communication protocols—without physical access to the rack. Configuration changes are validated before implementation to prevent invalid settings that could disrupt system operation.

Enhanced alarm aggregation: The 3500/05-01-02-00-00-01 consolidates alarm signals from all modules in the rack, providing a unified alarm status for the entire system. It prioritizes critical alarms (e.g., danger-level vibrations or speed excursions) and transmits them to external systems in real time, ensuring that operators receive timely notifications. This aggregated alarm data simplifies event analysis and reduces the burden on control system networks by minimizing redundant data transmission.

Typical application scenarios

In combined-cycle power plants, the 3500/05-01-02-00-00-01 integrates multiple 3500 series modules monitoring gas turbines, steam turbines, and generators. It coordinates data from 3500/25 149369-01 Keyphasor monitors (tracking shaft speed) and vibration monitors, then transmits synchronized data to the plant DCS via Ethernet. This enables operators to correlate turbine vibration patterns with rotational speed, facilitating early detection of issues like rotor imbalance or bearing degradation.

Within refineries, the module manages racks monitoring compressors and pumps. It aggregates data from vibration monitors, temperature sensors, and the 3500/25 149369-01 (tracking pump shaft speed), then sends consolidated information to the refinery’s SCADA system. Its alarm aggregation feature ensures that critical alerts—such as excessive vibration in a main feed pump—are prioritized and displayed prominently, enabling rapid response to prevent unplanned downtime.

In manufacturing facilities with distributed machinery, the 3500/05-01-02-00-00-01 connects 3500 racks across the plant via Ethernet. It enables centralized monitoring of multiple production lines, each with their own 3500/25 149369-01 modules and vibration monitors. Plant managers can access real-time data from all racks via a single HMI, streamlining maintenance planning and reducing the need for on-site inspections.

BENTLY 3500/05-01-02-00-00-01

Relationship with 3500/25 149369-01 and other modules

The 3500/05-01-02-00-00-01 is essential for maximizing the functionality of the 3500/25 149369-01 Keyphasor monitor and other 3500 series components:

With 3500/25 149369-01: It synchronizes Keyphasor data with vibration measurements, ensuring that speed and phase information is time-aligned with vibration signals. This synchronization is critical for order analysis, where vibration data is filtered by rotational speed to isolate faults like misalignment or gear wear.

With sensor cables (e.g., 133396-01): While the module does not directly interface with sensor cables, it relies on the clean signal transmission provided by 133396-01 (Keyphasor sensor cable) to ensure accurate data from the 3500/25 149369-01. It validates signal integrity and flags anomalies that may indicate cable degradation.

With communication gateways (e.g., 3500/92-04-01-00): It collaborates with gateways to extend network connectivity, routing data from the rack to cloud-based monitoring platforms or enterprise resource planning (ERP) systems for long-term analysis.

Related model recommendations

3500/05-01-01-00-00-01: A variant with enhanced security features (e.g., encrypted communication) for applications requiring compliance with industrial cybersecurity standards.

3500/25 149369-01: Keyphasor monitor module whose data is synchronized and routed by the 3500/05-01-02-00-00-01.

133396-01: Keyphasor sensor cable that provides clean signals to the 3500/25 149369-01, ensuring data quality for the 3500/05-01-02-00-00-01 to process.

3500/92-04-01-00: Communication gateway that works with the 3500/05-01-02-00-00-01 to extend connectivity to non-Ethernet protocols (e.g., Profibus).

3500/15 106M1079-01: Redundant power supply module that ensures continuous operation of the 3500/05-01-02-00-00-01 and connected components.

3500/55: Display module that receives data via the 3500/05-01-02-00-00-01 for local monitoring of rack status and measurements.

Installation, commissioning and maintenance instructions

Installation preparation: The 3500/05-01-02-00-00-01 must be installed as the first module in the 3500 rack (leftmost slot). Before installation, power off the rack and verify proper grounding. Required tools include a torque wrench (0.5-0.7Nm) and anti-static wrist strap. Inspect the module for physical damage and ensure the rack backplane is clean and free of debris.

Installation steps: Align the module with the rack guides, ensuring the backplane connector is properly positioned. Gently insert the module until the connector engages, then secure with mounting screws using the torque wrench. Connect Ethernet and RS-232 cables (if needed) after installation. Ensure Ethernet cables are shielded and routed away from high-voltage lines to prevent EMI.

Commissioning: Power on the rack and launch the 3500 configuration software. Connect to the 3500/05-01-02-00-00-01 via Ethernet or RS-232, then upload the rack configuration (including settings for the 3500/25 149369-01 and other modules). Verify communication with all modules by checking status indicators in the software. Test alarm transmission to external systems by simulating faults (e.g., exceeding vibration thresholds) and confirming alerts are received.

Maintenance suggestions: Perform monthly visual inspections to check for loose connections, overheating, or dust accumulation. Clean the module with a dry, lint-free cloth. Quarterly, verify Ethernet connectivity and configuration integrity using the 3500 software. Back up the rack configuration to a secure location to facilitate recovery in case of module failure. If communication issues arise, check Ethernet cable continuity (using a cable tester) and verify IP address settings. Replace damaged cables with shielded industrial-grade equivalents (e.g., Cat 5e or higher).

Service and guarantee commitment

The 3500/05-01-02-00-00-01 comes with a 12-month warranty covering manufacturing defects, including communication failures or backplane connector issues. During this period, we provide free repair or replacement of faulty units. Our technical support team offers 24/7 assistance for installation, configuration, and troubleshooting, with expertise in integrating the module with 3500/25 149369-01 and other 3500 series components.

For critical applications, optional extended warranties (up to 3 years) are available, including priority technical support, on-site commissioning assistance, and configuration backup services. Backed by BENTLY NEVADA’s decades of experience in machinery protection systems, the 3500/05-01-02-00-00-01 is guaranteed to deliver reliable performance as the central hub of your 3500 series monitoring system.