Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/05 |

| Manufacturer | BENTLY NEVADA |

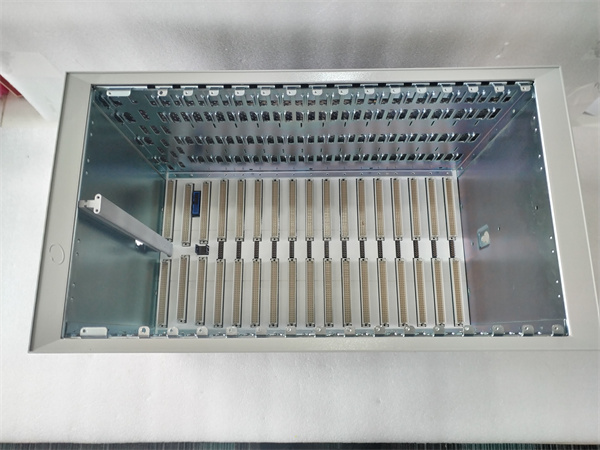

| Product category | Rack interface module |

| Electrical performance | 24V DC power supply; Power consumption: 4.5W max; Communication bus: 3500 system backplane |

| Physical size | Width: 24.4mm, Height: 241.3mm, Depth: 242mm |

| Interface type | Backplane connector for internal system communication; RS-232 port for local configuration; Ethernet port (10/100Base-T) for network connectivity |

| Communication protocol | Supports 3500 series proprietary protocol; Modbus TCP/IP over Ethernet; Compatible with system configuration software |

| Environmental requirements | Operating temperature: -40°C to +70°C; Humidity: 5% – 95%, non-condensing; Vibration resistance: 10g peak (10-2000Hz) |

| Installation method | Rack-mountable in 3500 series racks; Required as the first module in the rack (leftmost position) |

| Performance indicators | Data transfer rate: Up to 100Mbps over Ethernet; Supports up to 16 modules per rack; Configuration storage: Non-volatile memory |

BENTLY 3500/05

Product introduction

The BENTLY NEVADA 3500/05 is the foundational rack interface module of the 3500 series machinery protection system, serving as the central communication and control hub for all modules within a 3500 rack. It acts as the backbone that facilitates seamless data exchange between diverse components such as the advanced transducer signal conditioner 3500/42 176449-02, relay module 3500/60 163179-01, display module 3500/50 133388-02, and external systems like DCS, SCADA, or configuration software 170190-01E.

This module is responsible for coordinating the entire rack’s operations, including managing configuration data, aggregating alarms from all connected modules, and routing critical information to both local and remote monitoring systems. Its non-volatile memory ensures that rack configurations are preserved even during power disruptions, maintaining system integrity. With both local (RS-232) and network (Ethernet) connectivity options, the 3500/05 provides the flexibility needed for efficient system setup, monitoring, and integration into broader industrial automation networks.

Core advantages and technical highlights

Centralized system coordination: As the nerve center of the 3500 rack, the 3500/05 synchronizes data flow between all modules, including the 3500/42 176449-02. It ensures that conditioned signals from the 3500/42 176449-02 are time-aligned with data from other modules (such as vibration monitors or Keyphasor units), enabling accurate correlation of machinery parameters for diagnostics. This centralized coordination eliminates data latency issues that could compromise the analysis of interrelated measurements.

Unified alarm aggregation: The 3500/05 collects alarm signals from every module in the rack, including critical alerts from the 3500/42 176449-02 (e.g., temperature or pressure excursions) and the 3500/60 163179-01 (relay activations). It categorizes these alarms by severity, timestamps them, and transmits a consolidated alarm status to both the local 3500/50 133388-02 display and remote systems via Ethernet. This unified approach simplifies event analysis and ensures that operators receive a comprehensive view of system health.

Dual-mode communication: Equipped with RS-232 for local configuration and 10/100Base-T Ethernet for network integration, the 3500/05 offers versatile connectivity. The Ethernet port supports Modbus TCP/IP, enabling seamless integration with plant-wide control systems, while the RS-232 port allows direct access via laptops or HMIs for on-site troubleshooting. This duality ensures that the system remains accessible regardless of network status.

Robust configuration management: The module stores the entire rack configuration, including settings for the 3500/42 176449-02 (such as input types and filtering parameters) and other modules, in non-volatile memory. It supports remote configuration updates via Ethernet, allowing engineers to modify settings without physical access to the rack. Configuration changes are validated before implementation to prevent invalid parameters from disrupting system operation.

Typical application scenarios

In a combined-cycle power plant, the 3500/05 manages a rack containing the 3500/42 176449-02, 3500/60 163179-01, and vibration monitors. It collects conditioned temperature and pressure data from the 3500/42 176449-02 (connected to gas turbine sensors), aggregates alarms, and routes this information to the plant DCS via Ethernet. Operators use the 3500/50 133388-02 display (connected through the 3500/05) to monitor real-time values, while the module ensures that critical alarms trigger appropriate relays in the 3500/60 163179-01 to prevent equipment damage.

Within a refinery’s compressor station, the 3500/05 coordinates a rack monitoring multiple compressor parameters. It receives conditioned vibration, temperature, and pressure signals from the 3500/42 176449-02, processes these alongside data from Keyphasor modules, and transmits a unified data stream to the refinery’s SCADA system. During a pressure spike detected by the 3500/42 176449-02, the 3500/05 ensures the alarm is immediately relayed to both the 3500/60 163179-01 (triggering a shutdown) and the SCADA system, providing operators with full context for the event.

In a manufacturing facility with distributed production lines, multiple 3500/05 modules (each in separate racks) connect to a central monitoring system via Ethernet. Each 3500/05 manages data from a 3500/42 176449-02 monitoring line parameters (e.g., motor temperature, bearing vibration) and routes this information to the plant’s MES software. The modules’ non-volatile memory ensures that configuration settings for the 3500/42 176449-02 are preserved during power outages, minimizing downtime during recovery.

BENTLY 3500/05

Relationship with 3500/42 176449-02 and other modules

The 3500/05 is integral to maximizing the functionality of the 3500/42 176449-02 and other 3500 series components:

With 3500/42 176449-02: The 3500/05 serves as the primary interface for the 3500/42 176449-02 within the rack, receiving conditioned sensor data and distributing it to other modules and external systems. It stores the 3500/42 176449-02‘s configuration (e.g., thermocouple types, filtering settings) in non-volatile memory and enables remote updates to these parameters via 170190-01E software.

With 3500/60 163179-01: The 3500/05 sends aggregated alarm data to the relay module, ensuring that critical conditions detected by the 3500/42 176449-02 (e.g., high temperature) trigger appropriate relay actions (e.g., shutdowns). It also monitors the 3500/60 163179-01‘s status and reports relay activations to remote systems.

With 3500/50 133388-02: The display module receives real-time data and alarm statuses from the 3500/05, providing operators with a local visualization of information from the 3500/42 176449-02 and other modules. The 3500/05 enables two-way communication, allowing operators to adjust settings via the 3500/50 133388-02 that are then propagated to the 3500/42 176449-02.

With 3500/93: The communication gateway uses the 3500/05‘s Ethernet port to access rack data, including information from the 3500/42 176449-02, for transmission to cloud platforms or enterprise systems. This partnership extends the reach of the 3500/05‘s data beyond the local rack.

Related model recommendations

3500/05-01-02-00-00-01: A specific variant of the rack interface module with enhanced compatibility for large-scale systems.

3500/42 176449-02: Advanced transducer signal conditioner whose data is managed and distributed by the 3500/05.

3500/60 163179-01: Relay module that acts on alarm signals aggregated by the 3500/05.

3500/50 133388-02: Display module that visualizes data routed through the 3500/05.

170190-01E: Configuration software used to set up the 3500/05 and its connected modules, including the 3500/42 176449-02.

3500/93: Communication gateway that extends the 3500/05‘s data transmission capabilities to remote systems.

3500/15 106M1079-01: Redundant power supply that ensures continuous operation of the 3500/05 and connected modules.

Installation, commissioning and maintenance instructions

Installation preparation: The 3500/05 must be installed as the first module in the 3500 rack (leftmost slot) to ensure proper communication with all subsequent modules, including the 3500/42 176449-02. Power off the rack and verify proper grounding before installation. Required tools include a torque wrench (0.5-0.7Nm) and an anti-static wrist strap. Inspect the module for physical damage and ensure the rack backplane is clean.

Installation steps: Align the module with the rack guides, ensuring the backplane connector is correctly positioned. Gently insert the module until the connector engages, then secure it with mounting screws using the torque wrench. Connect Ethernet and RS-232 cables (if needed) after installation, using shielded Ethernet cables (e.g., 149992-01) to minimize EMI.

Commissioning: Power on the rack and launch the 170190-01E software. Connect to the 3500/05 via Ethernet or RS-232, then configure basic settings (IP address, subnet mask). Upload the rack configuration, including parameters for the 3500/42 176449-02 and other modules, and verify communication with all components using the software’s diagnostic tools. Test alarm propagation by simulating a fault in the 3500/42 176449-02 (e.g., exceeding a temperature threshold) and confirming the alarm is received by the 3500/60 163179-01 and displayed on the 3500/50 133388-02.

Maintenance suggestions: Perform monthly visual inspections to check for loose connections, dust accumulation, or overheating. Clean the module with a dry, lint-free cloth. Quarterly, verify configuration integrity using 170190-01E and test Ethernet connectivity. Back up the rack configuration to a secure location to facilitate recovery in case of module failure. If communication issues arise, check Ethernet cable continuity, IP address settings, and firewall rules to ensure the 3500/05 can communicate with both local modules and remote systems.

Service and guarantee commitment

The 3500/05 comes with a 12-month warranty covering manufacturing defects, including communication failures and backplane connector issues. During this period, we provide free repair or replacement of faulty units and 24/7 technical support for integration with the 3500/42 176449-02 and other modules.

Optional extended warranties (up to 3 years) are available, including priority technical support, on-site commissioning assistance, and configuration backup services. Backed by BENTLY NEVADA’s decades of expertise in machinery protection systems, the 3500/05 is guaranteed to deliver reliable performance as the central hub of your 3500 series monitoring system.