Description

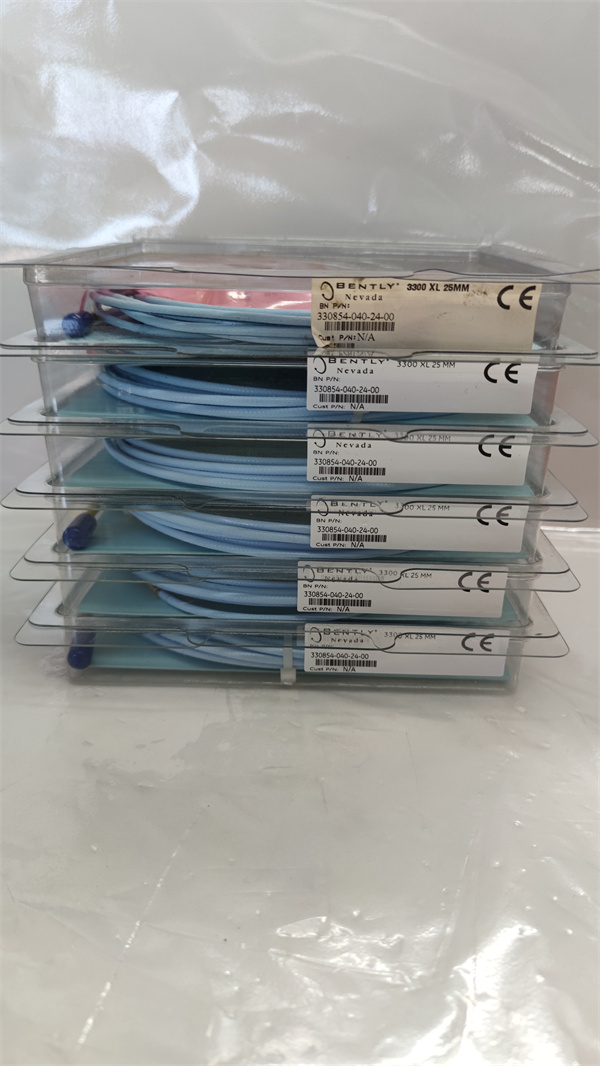

BENTLY 330854 – 040 – 24 – 00 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | 330854 – 040 – 24 – 00 |

| Manufacturer | BENTLY NEVADA |

| Product Category | Extension Cable |

| Cable Length | 4.0 meters (13.1 feet), denoted by ‘040’ in the model |

| Armor and Cable Type | High – temperature fluid loc cable, indicated by ’24’ in the model |

| Capacitance | 69.9 pf/m (21.3 pf/ft) typical |

| Material | 75 Ω triaxial, perfluoroalkoxyethylene (PFA) insulated fluid loc cable |

| Temperature Resistance | Operating and storage temperature: – 35 °C to + 200 °C (- 31 °F to + 392 °F) |

| Related System | Designed for use with the 3300 XL 25 mm system |

| Weight | 0.16 kg |

| Output Type | N/A (as it is a cable for connection, not an output – generating device) |

| Installation Type | Connects to relevant components in the system, typically in a plug – and – play manner (but proper grounding and connection procedures need to be followed) |

| Termination Type | Likely has a connector suitable for secure connection to the 3300 XL 25 mm system components, details not fully specified but may be a standard – type connector for the series |

| Application Areas | Machinery vibration monitoring systems, especially those related to the 3300 XL series; commonly used in industrial equipment such as steam turbines |

| Minimum Order Quantity | 1 (as per some product listings) |

| Price | ¥3,960.00 (as per one source, price may vary depending on supplier and market conditions) |

BENTLY 330854-040-24-00

Product Introduction

The BENTLY NEVADA 330854 – 040 – 24 – 00 is a specialized extension cable engineered for industrial applications, particularly within the realm of machinery vibration monitoring. It is an integral part of the 3300 XL 25 mm system, designed to provide a reliable connection solution in demanding industrial environments.

This extension cable is crafted with high – temperature fluid loc cable, ensuring its performance remains stable even in extreme temperature conditions. With a length of 4.0 meters, it offers flexibility in installation, allowing for proper placement of sensors and other components within the monitoring system. The use of 75 Ω triaxial, PFA – insulated fluid loc cable not only enhances its electrical conductivity but also contributes to its durability and resistance to harsh industrial elements.

Core Advantages and Technical Highlights

High – Temperature Resistance

One of the key advantages of the 330854 – 040 – 24 – 00 is its remarkable temperature resistance. With an operating and storage temperature range spanning from – 35 °C to + 200 °C, it can withstand the extreme heat often encountered in industrial settings such as power plants, steel mills, and refineries. In a power generation plant, for example, where steam turbines operate at high temperatures, this cable can maintain a stable connection between vibration sensors and the monitoring system, ensuring continuous and accurate data collection. This high – temperature resistance also reduces the risk of cable degradation over time, leading to increased reliability and a longer service life.

Precise Capacitance

The cable has a typical capacitance of 69.9 pf/m (21.3 pf/ft). This precise capacitance value is crucial for maintaining signal integrity in the vibration monitoring system. In machinery vibration monitoring, accurate transmission of sensor signals is essential for detecting even the slightest vibrations. The well – defined capacitance of this extension cable helps to minimize signal interference and distortion, enabling the monitoring system to receive clear and reliable data. This, in turn, allows for more accurate diagnosis of machinery health and early detection of potential mechanical issues.

Durable Material Construction

Constructed with 75 Ω triaxial, PFA – insulated fluid loc cable, the 330854 – 040 – 24 – 00 is built to last. The triaxial design provides enhanced shielding against electromagnetic interference, which is common in industrial environments filled with various electrical and mechanical equipment. The PFA insulation offers excellent chemical resistance, protecting the cable from corrosive substances that may be present in industrial processes. The fluid loc cable construction further contributes to its durability, making it suitable for use in areas where cables may be exposed to mechanical stress, such as in vibrating machinery or areas with frequent movement of equipment.

Typical Application Scenarios

In the power generation industry, the BENTLY 330854 – 040 – 24 – 00 is widely used in steam turbine monitoring systems. Steam turbines are critical components in power plants, and any abnormal vibration can lead to significant operational issues and potential damage. The extension cable connects vibration sensors installed on the turbine to the monitoring system, allowing operators to continuously monitor the turbine’s vibration levels. By providing a reliable connection even in the high – temperature environment of the turbine, it enables early detection of problems such as misalignment, bearing wear, or unbalanced rotors. This early detection can prevent costly turbine failures and ensure the stable operation of the power plant.

In the manufacturing sector, especially in plants with large – scale rotating machinery like motors and compressors, the cable plays a vital role. In a steel mill, for instance, large motors drive various mechanical processes. Monitoring the vibration of these motors is essential to prevent unexpected breakdowns that could disrupt production. The 330854 – 040 – 24 – 00 extension cable enables the connection of vibration sensors to the monitoring system, providing real – time data on motor vibrations. Maintenance teams can use this data to identify issues such as misalignment or worn – out bearings and schedule timely maintenance, thus minimizing production downtime.

Related Model Recommendations

3300 XL 8mm Proximity Transducer System Cables: While the 330854 – 040 – 24 – 00 is designed for the 3300 XL 25 mm system, the cables for the 3300 XL 8mm proximity transducer system are also from the BENTLY NEVADA product line. They may have different specifications in terms of length, capacitance, and cable type to suit the 8mm system requirements. However, they share the same high – quality standards and are suitable for use in similar industrial vibration – monitoring applications. In some cases, if the machinery being monitored has different sensor requirements or space limitations, the 3300 XL 8mm system cables may be a viable alternative.

3500 Series Cables: The 3500 series is another prominent product line from BENTLY NEVADA. Cables within this series are designed for use in the 3500 machinery protection system. Although they are part of a different system than the 3300 XL series, they offer similar functions in terms of providing reliable connections for monitoring various machinery parameters. If an industrial setup is based on the 3500 system, these cables can be used instead of the 330854 – 040 – 24 – 00 for connecting sensors and other components within that system. They may also have additional features or capabilities tailored to the specific requirements of the 3500 system, such as enhanced communication interfaces for data transfer within the system.

Generic High – Temperature Resistant Extension Cables: There are also generic high – temperature resistant extension cables available in the market. These cables may not be specifically designed for BENTLY NEVADA systems but can be used as a substitute in some cases. However, they may lack the precise engineering and compatibility features that the 330854 – 040 – 24 – 00 offers for the 3300 XL 25 mm system. Generic cables may not have the exact capacitance values required for optimal signal transmission in the BENTLY NEVADA vibration – monitoring system, and their durability and reliability in the long – term may also be a concern. They can be considered as a cost – effective option for less – critical applications or in situations where the exact specifications of the BENTLY NEVADA cable are not strictly required.

BENTLY 330854-040-24-00

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the BENTLY 330854 – 040 – 24 – 00 extension cable, ensure that the power to the 3300 XL 25 mm system is turned off. This is a crucial safety measure to prevent electrical shock during installation. The installation area should be clean and free from dust, debris, and any corrosive substances. Tools such as a screwdriver (if required for securing connectors) and cable strippers (if the cable needs to be terminated on – site) should be prepared. It is important to follow the grounding procedures specified in the 3300 XL 25 mm system manual. Proper grounding helps to minimize electrical interference and ensures the safe operation of the monitoring system. When handling the cable, avoid bending it at sharp angles, as this can damage the internal conductors and insulation.

Maintenance Suggestions

For regular maintenance, visually inspect the cable for any signs of physical damage, such as cuts, abrasions, or fraying of the outer sheath. Check the connectors for any signs of corrosion or looseness. If the cable is used in a high – temperature environment, periodically clean it to remove any accumulated dust or debris, as these can act as insulators and affect the cable’s ability to dissipate heat. In case of any connection issues, such as a loss of signal or intermittent data transmission, first check the cable connections at both ends. If necessary, use a multimeter to test the continuity of the cable and check for any breaks in the conductors. If a section of the cable is damaged, it may be possible to replace only the affected part, depending on the type of cable and the location of the damage. However, it is recommended to follow the manufacturer’s guidelines for cable repair or replacement.

Service and Guarantee Commitment

We are committed to the quality of the BENTLY 330854 – 040 – 24 – 00 extension cable. It comes with a comprehensive quality assurance program. In the event of any manufacturing defects, we will replace the cable free of charge within the warranty period. Our after – sales service is designed to be responsive and efficient. Our technical support team is available to assist with any installation – related questions, commissioning issues, or troubleshooting requirements. We strive to ensure that the 330854 – 040 – 24 – 00 continues to perform optimally throughout its service life, providing you with a reliable connection solution for your industrial vibration – monitoring needs.