Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

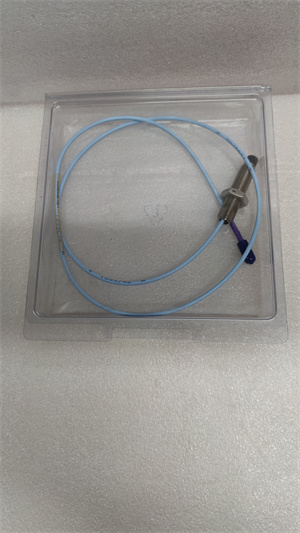

| Product Model | Bently Nevada 330703-000-060-10-02-00 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Category | Velocity Seismic Sensor |

| Measurement Range | 0.5 to 1000 Hz |

| Sensitivity | 20 mV/mm/s (±5%) |

| Frequency Response | 10 Hz to 1 kHz (±3dB) |

| Dynamic Range | >80 dB |

| Operating Temperature | -40°C to +100°C |

| Housing Material | 316 Stainless Steel |

| Mounting | M8 threaded stud |

| Weight | 450 g |

| Cable Length | 10 meters |

| Certifications | ATEX, IECEx, API 670 |

BENTLY 330703-000-060-10-02-00

Product Introduction

The Bently Nevada 330703-000-060-10-02-00 is a high-performance velocity seismic sensor designed for permanent machinery monitoring in demanding industrial environments. Part of Bently Nevada’s 3300 series condition monitoring systems, this rugged sensor provides reliable vibration measurement for predictive maintenance of large rotating equipment including turbines, compressors, and pumps.

Featuring a heavy-duty 316 stainless steel housing, the sensor withstands harsh plant conditions while delivering precise velocity-based vibration data (20 mV/mm/s sensitivity). The integrated 10-meter armored cable ensures signal integrity in electrically noisy environments, making it ideal for power generation, oil & gas, and heavy industry applications.

Core Advantages and Technical Highlights

Precision Vibration Monitoring:

10 Hz to 1 kHz frequency range covers most machinery defects

20 mV/mm/s sensitivity with ±5% tolerance for consistent measurements

Velocity measurement ideal for low-to-medium speed equipment

AC output signal eliminates DC drift issues

Industrial Durability:

316 stainless steel construction resists corrosion

M8 threaded stud mounting for secure installation

-40°C to +100°C operating range

ATEX/IECEx certified for hazardous areas

API 670 compliant for refinery applications

Reliable Signal Transmission:

10-meter integral armored cable with strain relief

EMI/RFI shielding for noise immunity

Hermetically sealed against moisture ingress

450g mass provides excellent mechanical coupling

BENTLY 330703-000-060-10-02-00

Typical Application Scenarios

Power Generation:

Steam turbine bearing housing monitoring

Generator frame vibration

Cooling water pump assessment

Oil & Gas:

Reciprocating compressor vibration

Pipeline pump monitoring

Offshore platform machinery

Heavy Industry:

Rolling mill drives

Mine hoist machinery

Cement kiln support rollers

Related Model Recommendations

Bently Nevada 330703-000-050-05-02-00: 5m cable version

Bently Nevada 330701: Accelerometer alternative

Bently Nevada 3500/42M: Vibration monitor

Bently Nevada 3300/20: Proximitor power supply

Bently Nevada 1900/65A: Portable vibration analyzer

Installation and Commissioning

Installation:

Mount on clean, flat surface perpendicular to vibration

Use proper torque on M8 mounting stud

Route cable away from interference sources

Verify proper grounding

Commissioning:

Check baseline vibration levels

Verify signal to monitoring system

Set appropriate alarm thresholds

Document initial readings

Maintenance:

Annual calibration verification

Regular cable inspections

Monitoring of trend data

Replacement per OEM schedule

Service and Guarantee Commitment

24-month warranty

Global technical support

Calibration services

Repair programs

Lifetime product support