Description

Technical Specifications Table

| Parameter | Specification |

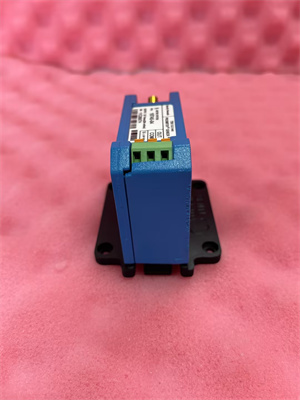

| Model Number | Bently Nevada 18745-04 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Piezoelectric Accelerometer |

| Sensitivity | 100 mV/g (±5%) |

| Frequency Range | 1 Hz to 10 kHz (±3 dB) |

| Measurement Range | ±50 g peak |

| Output Signal | 2-wire, 4-20 mA |

| Power Supply | 18-30 VDC loop powered |

| Resonant Frequency | >25 kHz |

| Housing Material | 316 Stainless Steel |

| Mounting | M6 threaded stud |

| Environmental Rating | IP67 |

| Operating Temperature | -40°C to +120°C (-40°F to +248°F) |

| Compliance | API 670, ISO 10816 |

BENTLY 18745-04

Product Overview

The Bently Nevada 18745-04 is a rugged industrial accelerometer designed for continuous vibration monitoring of rotating machinery in demanding environments. This high-performance sensor provides reliable acceleration measurements for condition-based maintenance programs, enabling early detection of developing mechanical faults.

As part of Bently Nevada’s comprehensive machinery protection portfolio, the 18745-04 features robust construction with all-welded stainless steel housing and integrated electronics. Its wide frequency range and excellent temperature stability make it particularly suitable for monitoring high-speed equipment where early detection of bearing defects and other mechanical issues is critical.

Key Features and Benefits

Precision Measurement Capabilities:

Wide frequency response (1 Hz to 10 kHz) captures both low and high-frequency vibration components

High sensitivity (100 mV/g) ensures accurate detection of subtle vibration changes

Excellent signal-to-noise ratio for reliable diagnostics

4-20 mA output for direct integration with control systems

Durable Industrial Design:

316 stainless steel housing resists corrosion and mechanical damage

Hermetically sealed construction (IP67) protects internal components

Withstands high levels of mechanical shock (up to 500 g)

Integrated electronics eliminate need for separate charge amplifiers

Installation and Maintenance Advantages:

Compact, low-profile design fits in space-constrained locations

Standard M6 mounting thread for secure attachment

Integral cable with strain relief for reliable connections

Maintenance-free operation with no moving parts

Industrial Applications

The Bently Nevada 18745-04 is ideally suited for:

Power Generation: Steam and gas turbine bearing monitoring

Oil & Gas: Compressor and pump vibration measurement

Petrochemical: Critical rotating equipment protection

Wind Turbines: Gearbox and generator monitoring

Pulp & Paper: Roll and dryer section vibration analysis

Typical monitored faults include:

Bearing defects (inner/outer race, rolling element)

Gear tooth damage

Mechanical looseness

Rotor rub conditions

Imbalance and misalignment

BENTLY 18745-04

Compatible and Related Products

Bently Nevada 18745-05: High-temperature version (+150°C limit)

Bently Nevada 18745-06: Hazardous area certified (ATEX/IECEx) variant

Bently Nevada 3300/25: Seismic monitor for vibration measurement

Bently Nevada 3500/42: Vibration monitor for system integration

Bently Nevada 1900/65: Proximity transducer system for displacement measurement

Installation and Maintenance Guidelines

Installation Best Practices:

Mount directly on machine bearing housings at measurement points

Ensure clean, flat mounting surface (surface finish <3.2 μm Ra)

Tighten to recommended torque (typically 5-7 Nm)

Route cable away from moving parts and heat sources

Use proper cable glands for environmental protection

Maintenance Recommendations:

Annual visual inspection of sensor and cable

Verify mounting integrity during routine maintenance

Check for proper signal output during system calibration

Replace if physical damage is observed or measurements become erratic

Use only genuine Bently Nevada replacement parts

Warranty and Support

Bently Nevada provides:

24-month standard warranty

Global technical support network

Application engineering assistance

Comprehensive documentation

Calibration and repair services

The 18745-04 accelerometer is backed by Bently Nevada’s extensive experience in machinery protection systems, ensuring reliable performance throughout its service life.

This technical product description provides a complete overview of the Bently Nevada 18745-04 accelerometer, presenting detailed specifications, features, and application information in a professional format suitable for industrial users and procurement specialists. The content is optimized for both technical accuracy and marketing effectiveness while maintaining readability.