Description

Technical Specifications Table

| Parameter | Specification |

| Model Number | Bently Nevada 146031-02 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Seismic Velocity Sensor |

| Measurement Range | 0-25.4 mm/s (1 in/s) peak |

| Frequency Response | 10 Hz to 1 kHz (±3 dB) |

| Sensitivity | 200 mV/mm/s (5.0 mV/mil/s) |

| Output Signal | 2-wire, 4-20 mA |

| Power Supply | 18-30 VDC loop powered |

| Housing Material | 316 Stainless Steel |

| Mounting | M10 x 1.5 threaded stud |

| Operating Temperature | -40°C to +150°C (-40°F to +302°F) |

| Environmental Rating | IP67 |

| Shock Resistance | 100 g, 11 ms half-sine |

| Compliance Standards | API 670, ISO 10816 |

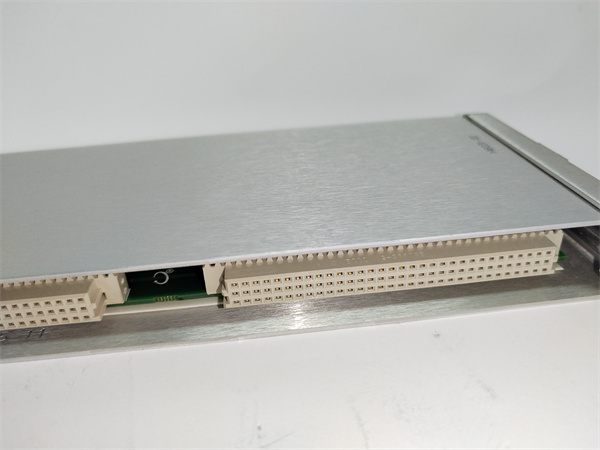

BENTLY 146031-02

Product Overview

The Bently Nevada 146031-02 is an industrial-grade seismic velocity transducer designed for continuous vibration monitoring in extreme operating environments. This high-temperature variant of Bently Nevada’s proven velocity sensor platform delivers reliable machinery protection in applications where elevated temperatures would compromise standard sensors.

Featuring an extended temperature range up to 150°C (302°F), the 146031-02 maintains measurement accuracy in hot oil pumps, gas turbine enclosures, and other high-heat applications. Its all-welded 316 stainless steel construction provides exceptional durability while the hermetic seal prevents moisture ingress in challenging industrial environments.

Key Features and Benefits

High-Temperature Performance:

Extended operating range to +150°C (+302°F)

Stable sensitivity across full temperature range

Special high-temp cable materials

Thermal isolation design

Precision Vibration Measurement:

Wide frequency response (10 Hz to 1 kHz)

Excellent linearity (±5% typical)

4-20 mA output for direct system integration

High signal-to-noise ratio

Rugged Industrial Design:

316 stainless steel housing

Hermetically sealed construction

Withstands 100 g mechanical shock

IP67 environmental protection

Installation Guidelines

BENTLY 146031-02

Mounting Requirements:

Clean, flat mounting surface (Ra < 3.2 μm)

Secure to machine housing using M10 stud

Recommended torque: 20 Nm (±10%)

Maintain minimum 25 mm clearance

Electrical Connections:

Use shielded cable for all connections

Properly ground shield at monitor end only

Verify polarity before power-up

Check for proper loop current

High-Temp Considerations:

Allow for thermal expansion

Avoid direct heat sources on cable

Use high-temp cable ties

Route cables away from hot surfaces

Maintenance Procedures

Routine Checks:

Monthly visual inspections

Verify tightness of mounting hardware

Check cable condition

Confirm proper signal output

Calibration:

Annual sensitivity verification

Check against reference standard

Record calibration results

Replace if out of tolerance

Troubleshooting:

Zero output: Check power and connections

Erratic signal: Inspect for cable damage

Drifting baseline: Verify mounting integrity

Noise issues: Confirm proper grounding

Warranty and Support

Coverage:

24-month limited warranty

Defects in materials/workmanship

Excludes improper installation/misuse

Support Services:

Global technical assistance

Application engineering

Repair and recalibration

Spare parts availability

Documentation:

Installation manuals

Technical bulletins

Application notes

Safety guidelines

The Bently Nevada 146031-02 combines proven velocity measurement technology with enhanced high-temperature capabilities for reliable machinery protection in the most demanding industrial applications.