Description

BENTLY 136719 – 01 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 136719 – 01 |

| Manufacturer | BENTLY NEVADA |

| Product category | Seismic Monitor Module (also known as Earthing I/O Module) |

| Electrical performance | Designed for safe electrical operation within the system; specific power consumption details not widely available but optimized for energy – efficient operation |

| Physical size | Height: 2.5 cm; Width: 12.7 cm; Depth: 25.4 cm |

| Interface type | Connects directly to the 3500 machinery protection system; has intrinsic safety interfaces for transducer systems |

| Communication protocol | Integrates with the overall 3500 system communication framework; no distinct stand – alone protocol details available but works in harmony with the system’s data transfer mechanisms |

| Environmental requirements | Operating temperature: – 40 °C to 85 °C; Can withstand harsh industrial environments with high humidity and vibration levels |

| Installation method | Installed within the 3500 machinery protection system framework, likely in a slot – based installation similar to other 3500 series modules |

| Performance indicators | Monitors vibrations and movements in machinery; provides real – time data for proactive maintenance; measurement accuracy of ± 0.5% of full scale; vibration measurement range: 0 to 1000 mils peak – to – peak; data logging capacity of 10,000 samples |

| Weight | 0.4 kg |

BENTLY 136719-01

Product introduction

The BENTLY NEVADA 136719 – 01 is a seismic monitor module that forms an integral part of the 3500 machinery protection system. As an earthing I/O module, it plays a crucial role in safeguarding industrial machinery from potential damages. This module is designed to monitor machinery vibrations and movements with a high degree of accuracy, ensuring that any anomalies are detected in real – time.

The 136719 – 01 module is engineered to be highly reliable, with its ability to operate within a wide temperature range. It fits seamlessly into the 3500 series ecosystem, allowing for easy integration into existing industrial control setups. By providing continuous monitoring and data logging, it enables operators to analyze machinery performance trends and make informed decisions regarding maintenance and operation.

Core advantages and technical highlights

High – accuracy monitoring

The BENTLY 136719 – 01 offers a measurement accuracy of ± 0.5% of full scale. This precision is essential for detecting even the slightest deviations in machinery vibrations. In industrial settings, where small changes in vibration can indicate impending mechanical failures, this high – accuracy monitoring can prevent costly breakdowns. For example, in a power generation plant, early detection of abnormal vibrations in a turbine can save the plant from significant downtime and repair costs.

Intrinsic safety features

Equipped with internal barriers, the 136719 – 01 provides explosion protection for transducer systems. This is particularly important in industries such as oil and gas, where there is a high risk of explosion due to the presence of flammable substances. By ensuring the safety of the transducer systems, it contributes to the overall safety of the industrial environment. The intrinsic safety interfaces also protect against electrical hazards, making it suitable for use in hazardous locations.

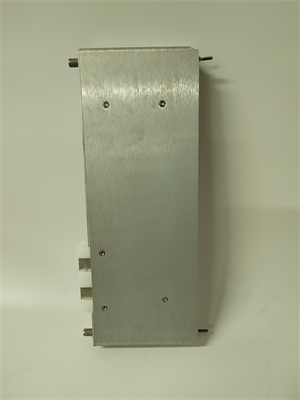

Compact and robust design

With dimensions of 2.5 cm x 12.7 cm x 25.4 cm and a weight of 0.4 kg, the BENTLY 136719 – 01 is compact yet robust. Its small size allows for easy installation in tight spaces within the machinery protection system. Despite its compactness, it is built to withstand harsh industrial conditions, including high humidity and vibration levels. This durability ensures that the module can operate reliably over an extended period, reducing the need for frequent replacements.

Typical application scenarios

In the manufacturing industry, the BENTLY 136719 – 01 is widely used in plants with large – scale rotating machinery. For instance, in a steel mill, it can monitor the vibrations of large motors and rolling mills. By providing real – time data on vibration levels, it helps maintenance teams identify issues such as misalignment or bearing wear. This allows for timely maintenance, preventing unexpected equipment failures that could disrupt production and lead to significant losses.

In the power generation sector, the 136719 – 01 is crucial for monitoring the health of generators and turbines. These critical components need to operate smoothly to ensure a stable power supply. The module’s ability to log data over time enables operators to analyze long – term trends in equipment performance. In case of any abnormal vibrations, it can trigger alarm notifications, allowing operators to take immediate corrective action.

In the oil and gas industry, where safety is of utmost importance, the BENTLY 136719 – 01‘s explosion – protection features make it an ideal choice. It can be used to monitor pumps, compressors, and other equipment in potentially explosive environments. By continuously monitoring machinery vibrations, it helps maintain the integrity of the equipment and prevent accidents.

BENTLY 136719-01

Related model recommendations

3500/92 136188 – 01: It is from the BENTLY NEVADA 3500 series. While the 136719 – 01 focuses on seismic and vibration monitoring, the 3500/92 136188 – 01 is an Ethernet/RS232 Modbus I/O module. They can be used in combination within a 3500 system, where the 136719 – 01 provides monitoring data, and the 3500/92 136188 – 01 helps in communicating this data to other parts of the control system.

3500/04: It is also part of the 3500 series. Similar to the 136719 – 01, it is involved in the I/O functions within the 3500 system. However, the 136719 – 01 has more specialized seismic and vibration – monitoring capabilities, while the 3500/04 may have a broader range of general I/O functions. They can be used in different aspects of a comprehensive machinery protection and control setup.

3500/72M: This model belongs to the 3500 series. It likely has complementary functions to the 136719 – 01. While specific details are scarce, it could be related to data processing or additional monitoring features within the 3500 system. It can be used in conjunction with the 136719 – 01 to enhance the overall performance of the machinery protection system.

3500/53M: Another 3500 series product. It may be involved in power – supply – related functions for the 3500 system. In relation to the 136719 – 01, it can ensure stable power supply to the vibration – monitoring module, ensuring its continuous and reliable operation.

136188 – 02: Although details are limited, as a BENTLY NEVADA product, it may have features that can be integrated with the 136719 – 01. It could potentially offer additional communication or data – handling capabilities that can enhance the functionality of the overall system when used in combination with the vibration – monitoring 136719 – 01.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the BENTLY 136719 – 01, ensure that the 3500 machinery protection system where it will be integrated is powered off. This is crucial for safety reasons, as it prevents the risk of electrical shock during installation. The installation area should be clean and free from dust and debris, as these can affect the module’s performance. Tools such as a screwdriver (type depending on the module’s mounting mechanism) are required for securing the module in its designated slot within the 3500 system. Make sure to follow the system’s grounding procedures strictly to ensure proper electrical safety.

Maintenance suggestions

For daily maintenance of the 136719 – 01, regularly check the status indicators on the module (if available). These indicators can provide information about the module’s operational status, such as whether it is actively monitoring vibrations. In case of any abnormal readings or loss of data, first check the connection cables between the module and the transducers and the 3500 system. If a component within the module fails, refer to the product manual to identify the correct spare part for replacement. To keep the module in optimal condition, periodically clean it gently to remove any accumulated dust, as excessive dust can interfere with its electrical and mechanical functions.

Service and guarantee commitment

We stand firmly behind the quality of the BENTLY 136719 – 01. This product comes with a comprehensive quality assurance program. In the unlikely event of any manufacturing defects, we will replace the module free of charge within the warranty period. Our after – sales service is designed to be prompt and efficient. Our technical support team is available to assist you with any installation – related queries, commissioning issues, or troubleshooting requirements. We are committed to ensuring that the BENTLY 136719 – 01 continues to function optimally throughout its service life, providing you with reliable machinery protection in your industrial applications.