Description

Technical Specifications Table

| Parameter | Specification |

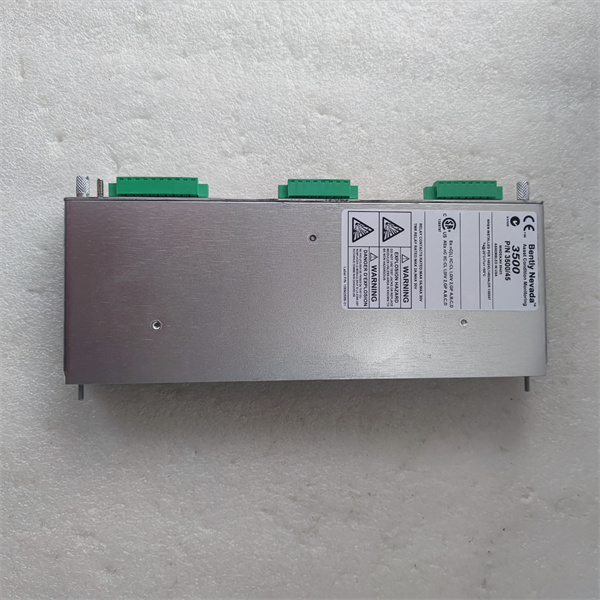

| Model Number | Bently Nevada 135137-01 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Proximity Transducer System |

| Measurement Range | 0.08 to 2.36 in (2 to 60 mm) |

| Output Signal | -4 to -20 VDC (LVDT) |

| Frequency Response | 0 to 10 kHz |

| Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Power Requirement | 18-30 VDC, 10 mA typical |

| Probe Diameter | 8 mm standard |

| Cable Length | 20 ft (6 m) standard |

| Environmental Rating | IP67 |

| Compliance | API 670, ISO 10816 |

BENTLY 135137-01

Product Overview

The Bently Nevada 135137-01 represents a high-performance proximity transducer system engineered for critical machinery monitoring applications. As part of Bently Nevada’s comprehensive condition monitoring solutions, this system provides precise measurement of shaft vibration and position in demanding industrial environments.

Designed for reliability and accuracy, the Bently Nevada 135137-01 integrates a robust probe, high-quality extension cable, and signal conditioning electronics to deliver stable, repeatable measurements. The system’s wide operating temperature range and IP67 protection rating ensure dependable performance in challenging conditions, from offshore oil platforms to power generation facilities.

Key Features and Benefits

Precision Measurement:

The Bently Nevada 135137-01 offers exceptional measurement accuracy with a linear range of 0.08 to 2.36 inches, capable of detecting subtle changes in shaft position that may indicate developing machinery faults. The system’s high-frequency response (0 to 10 kHz) captures dynamic motion characteristics critical for vibration analysis.

Robust Construction:

Engineered for industrial durability, the system features a stainless steel probe housing resistant to corrosion and mechanical stress. The high-temperature rated cables maintain signal integrity even in extreme operating environments, while the IP67 rating ensures protection against dust and moisture ingress.

Flexible Integration:

The Bently Nevada 135137-01 is designed for seamless integration with Bently Nevada’s monitoring systems and third-party control equipment. The standard 20-foot cable length accommodates most installation requirements, with options for custom lengths when needed. The system’s compliance with API 670 and ISO 10816 standards guarantees its suitability for critical machinery protection applications.

Industrial Applications

The Bently Nevada 135137-01 is ideally suited for:

Power Generation: Continuous monitoring of turbine shafts in steam, gas, and hydroelectric power plants

Oil & Gas: Critical vibration monitoring of compressors, pumps, and motors in upstream and downstream operations

Petrochemical: Protection of large rotating equipment in refineries and chemical processing plants

Heavy Industry: Condition monitoring of large motors, gearboxes, and other critical machinery in mining and metals applications

The system’s ability to provide early warning of developing machinery problems makes it invaluable for predictive maintenance programs, helping to prevent costly unplanned downtime and catastrophic failures.

Compatible and Related Products

Bently Nevada 135137-02: Extended temperature range version (-60°C to +150°C)

Bently Nevada 135137-03: Hazardous area certified (ATEX/IECEx) variant

Bently Nevada 3300 XL 8mm: Proximity probe with integrated electronics

Bently Nevada 3500/42: Monitor for radial vibration measurement

Bently Nevada 1900/65: High-temperature proximity transducer system

Bently Nevada 330180-50-00: Extension cable assembly for harsh environments

BENTLY 135137-01

Installation and Maintenance Guidelines

Installation Requirements:

The Bently Nevada 135137-01 requires proper grounding of the monitoring system and careful verification of clearance between the probe tip and target surface. Mounting location should be free from excessive vibration and within specified temperature limits. Use provided alignment tools for precise probe positioning.

Maintenance Recommendations:

Regular inspection of cables for damage or wear

Periodic verification of probe gap voltage during routine maintenance

Annual system recalibration per OEM specifications

Keep probe tips clean and free from buildup

Use only genuine Bently Nevada replacement parts

Warranty and Support

Bently Nevada provides a comprehensive 24-month warranty for the 135137-01 system, covering defects in materials and workmanship. Customers benefit from Baker Hughes’ global support network, including:

24/7 technical assistance

On-site service options

Application engineering support

Training and certification programs

The product is backed by Bently Nevada’s extensive expertise in machinery protection systems and condition monitoring solutions.

This technical product description provides a complete overview of the Bently Nevada 135137-01 proximity transducer system, highlighting its technical specifications, features, applications, and support services while maintaining a professional, marketing-appropriate tone. The information is structured for easy reference and optimized for industrial automation professionals seeking detailed product information.