Description

Technical Specifications Table

| Parameter | Specification |

| Model Number | Bently Nevada 128229-01 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Seismic Velocity Sensor |

| Measurement Range | 0-25.4 mm/s (1 in/s) peak |

| Frequency Response | 10 Hz to 1 kHz (±3 dB) |

| Sensitivity | 200 mV/mm/s (5.0 mV/mil/s) |

| Output Signal | 2-wire, 4-20 mA |

| Power Supply | 18-30 VDC loop powered |

| Housing Material | 316 Stainless Steel |

| Mounting | M10 x 1.5 threaded stud |

| Operating Temperature | -40°C to +120°C (-40°F to +248°F) |

| Environmental Rating | IP67 |

| Shock Resistance | 100 g, 11 ms half-sine |

| Compliance Standards | API 670, ISO 10816 |

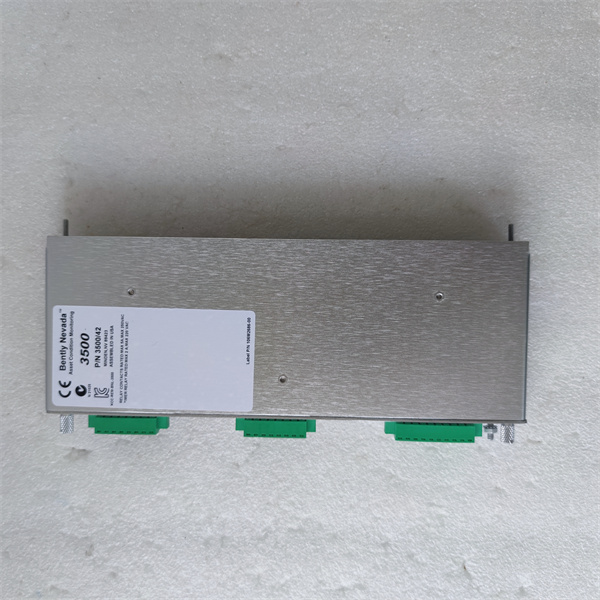

BENTLY 128229-01

Product Overview

The Bently Nevada 128229-01 is a rugged industrial velocity transducer designed for continuous vibration monitoring of rotating machinery in demanding environments. This seismic sensor provides reliable velocity measurements for condition monitoring and predictive maintenance programs, enabling early detection of mechanical faults before catastrophic failure occurs.

As part of Bently Nevada’s comprehensive machinery protection portfolio, the 128229-01 features all-welded stainless steel construction with hermetic sealing for maximum durability. Its wide operating temperature range and IP67 environmental rating make it suitable for harsh applications in power generation, oil & gas, and heavy industry.

Key Features and Benefits

Precision Measurement:

Wide frequency response captures critical vibration components (10 Hz-1 kHz)

High sensitivity (200 mV/mm/s) for accurate diagnostics

Excellent linearity (±5% typical) across measurement range

Stable 4-20 mA output for direct system integration

Robust Construction:

316 stainless steel housing resists corrosion

Hermetically sealed against moisture ingress

Withstands 100 g mechanical shock

Vibration resistant to 20 g RMS

Installation Advantages:

Standard M10 mounting thread

Compact, low-profile design

Integral cable with strain relief

Maintenance-free operation

Industrial Applications

Power Generation:

Steam turbine bearing monitoring

Generator vibration analysis

Cooling fan condition monitoring

Oil & Gas:

Centrifugal compressor protection

Pump vibration monitoring

Gas turbine auxiliary systems

Heavy Industry:

Large motor bearing analysis

Gearbox vibration monitoring

Rolling mill equipment protection

Installation Guidelines

BENTLY 128229-01

Mounting Surface Preparation:

Clean, flat surface (Ra < 3.2 μm)

Degrease mounting area

Apply light thread lubricant

Sensor Installation:

Hand-tighten plus 1/4 turn with wrench

Recommended torque: 20 Nm (±10%)

Avoid over-tightening

Cable Routing:

Use proper cable glands

Maintain minimum bend radius

Secure at regular intervals

Electrical Connections:

Verify proper polarity

Check power supply (18-30 VDC)

Confirm 4-20 mA output range

Maintenance Procedures

Quarterly:

Visual inspection of sensor and cable

Verify mounting integrity

Check for corrosion or damage

Annually:

Sensitivity verification

Frequency response check

Cable integrity test

Troubleshooting:

No output: Check power and connections

Erratic signal: Inspect for cable damage

Drifting baseline: Verify mounting

Noise issues: Confirm proper grounding

Warranty and Support

Coverage:

24-month limited warranty

Covers defects in materials/workmanship

Excludes physical damage or misuse

Support Services:

Global technical assistance

Application engineering

Repair and recalibration

Spare parts availability

Documentation:

Installation manuals

Technical bulletins

Safety guidelines

Certificates of conformance

The Bently Nevada 128229-01 provides reliable vibration monitoring for predictive maintenance programs, helping to prevent unexpected machinery failures in critical industrial applications.