Description

Technical Specifications Table

| Parameter | Specification |

| Model Number | Bently Nevada 106M1081-01 |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Product Type | Vibration Monitoring Module |

| Input Channels | 2 independent vibration channels |

| Measurement Range | 0-20 mm/s RMS velocity (configurable) |

| Frequency Range | 10 Hz to 1 kHz (±3 dB) |

| Signal Inputs | Accepts velocity, acceleration, or proximity signals |

| Output Signals | 4-20 mA (per channel), relay contacts |

| Power Supply | 90-264 VAC, 50/60 Hz or 24 VDC |

| Operating Temperature | -20°C to +70°C (-4°F to +158°F) |

| Enclosure Rating | IP66/NEMA 4X |

| Communication | RS-485 Modbus RTU |

| Dimensions | 150 x 100 x 60 mm (5.9 x 3.9 x 2.4 in) |

| Compliance | API 670, ISO 10816 |

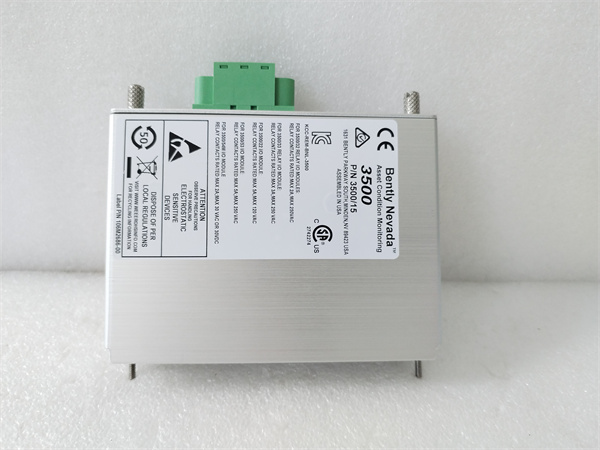

BENTLY 106M1081-01

Product Overview

The Bently Nevada 106M1081-01 is a sophisticated vibration monitoring module designed for continuous condition monitoring of critical rotating machinery. This compact yet powerful unit provides reliable vibration measurement and analysis for predictive maintenance programs in industrial environments.

As part of Bently Nevada’s machinery protection portfolio, the 106M1081-01 offers dual-channel capability in a rugged enclosure, making it suitable for standalone installations or integration into larger monitoring systems. Its flexible input configuration supports various sensor types, including velocity seismometers, accelerometers, and proximity probes.

Key Features and Benefits

Advanced Monitoring Capabilities:

Dual independent monitoring channels

Programmable alarm setpoints with adjustable delay timers

Built-in dynamic signal processing

Configurable for velocity, acceleration, or displacement measurements

Robust System Design:

Industrial-grade enclosure (IP66/NEMA 4X)

Wide operating temperature range

Dual power supply options (AC/DC)

Electrically isolated inputs

Integration Flexibility:

Analog (4-20 mA) and digital (Modbus) outputs

Compatible with Bently Nevada System 1® software

Supports integration with DCS and PLC systems

Field-configurable for various sensor types

Industrial Applications

Power Generation:

Steam turbine bearing monitoring

Generator vibration analysis

Auxiliary pump protection

Oil & Gas:

Centrifugal compressor monitoring

Pipeline pump protection

Gas turbine auxiliary systems

Heavy Industry:

Large motor vibration monitoring

Gearbox condition assessment

Rolling mill equipment protection

Compatible Sensors

Bently Nevada 3300 XL Proximity Probes

Bently Nevada 18745 Series Accelerometers

Bently Nevada 133442 Velocity Seismometers

Bently Nevada 1900/65 High-Temperature Sensors

Third-party sensors with compatible outputs

BENTLY 106M1081-01

Installation Guidelines

Electrical Connections:

Use shielded cable for all sensor connections

Maintain proper grounding practices

Observe polarity for powered sensors

Verify signal levels before commissioning

Mounting Requirements:

Install in accessible location

Allow minimum 50 mm clearance around unit

Secure firmly to vibration-free surface

Protect from direct water spray

Configuration Steps:

Set measurement parameters (velocity/acceleration/displacement)

Configure alarm setpoints

Adjust filter settings as required

Verify output scaling

Test alarm functionality

Maintenance Procedures

Routine Checks:

Monthly visual inspection

Quarterly connection tightness verification

Annual calibration check

Diagnostic Features:

Built-in signal validation

Sensor fault detection

System health monitoring

Event capture capability

Troubleshooting:

LED status indicators

Modbus-accessible diagnostics

Output signal verification

Sensor loop testing

Warranty and Support

Coverage:

24-month standard warranty

Defects in materials and workmanship

Global technical support

Services:

Application engineering

Configuration assistance

Repair and recalibration

Software updates

Documentation:

Installation manual

Configuration guide

Technical specifications

Certificates of compliance

The Bently Nevada 106M1081-01 provides reliable vibration monitoring for critical machinery protection applications, combining advanced measurement capabilities with rugged industrial construction for dependable operation in demanding environments.