Description

Key Technical Specifications

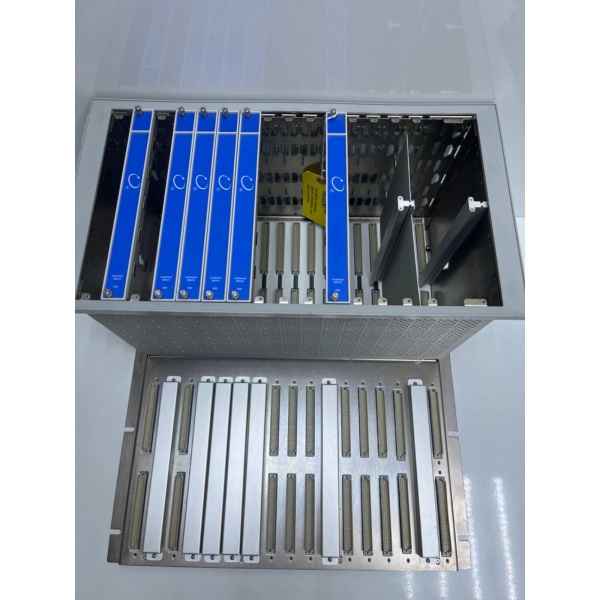

- Model Number: 3500/05 130768-01

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Rack Type: Passive backplane rack (no active components)

- Slot Capacity: Full-size (14 slots for 1U 3500 modules); Mini (7 slots, 12-inch height)

- Backplane Function: Distributes 24VDC power; enables module-to-module communication (100Mbps)

- Power Compatibility: 3500/10 Power Modules (1 or 2 for N+1 redundancy)

- Mounting Options: 19-inch EIA rack-mount, panel-mount, bulkhead-mount (front-access only)

- Environmental Ratings: Operating Temp: -30°C to +65°C (-22°F to +150°F); Humidity: 95% non-condensing

- Cover Kit Contents: 1 full-height blank front panel, 1 I/O module cover, mounting hardware (130768-01)

- Weight: Full-size: 3kg (6.6lbs) (empty); Mini: 1.8kg (4lbs) (empty)

- Certifications: CE, UL 508, ATEX Zone 2, IECEx, API 670 compliant

- Compatibility: 3500/22M/42M Monitoring Modules, 3500/25 Relay Modules, 3500/94 Communication Modules

- Mechanical Design: Steel chassis with keyed module slots (prevents misinstallation); anti-vibration mounting points

Bently Nevada 3500/05 130768-01

Field Application & Problem Solved

In critical machinery protection—power plant steam turbines, refinery gas compressors, chemical plant centrifugal pumps—the 3500 system’s modules need a rugged, purpose-built rack to function reliably. Generic industrial racks fail in three critical ways: they lack keyed slots (causing module misalignment and communication drops), don’t integrate with the 3500 backplane (leading to power distribution issues), and leave unused slots open (allowing dust/moisture ingress that fries electronics). A Texas refinery lost $270k in a 3.5-hour outage when a generic rack’s misaligned slots damaged a 3500/42M module’s backplane pins, leaving a turbine unmonitored. A Pennsylvania power plant spent $22k annually replacing modules damaged by dust entering open slots in non-Bently racks.

This rack solves these issues as the factory-designed backbone of the 3500 system. You’ll find it in control rooms, turbine enclosures, and compressor skid panels—anywhere 3500 modules are deployed to protect critical rotating assets. It’s mandatory for API 670-compliant systems, as its structured design ensures module placement and environmental protection meet industry safety standards.

Its core value is 3500-native integration + failure-proof module alignment + environmental hardening. Unlike generics, it’s engineered to the exact mechanical/electrical specs of 3500 modules, eliminating communication latency. The blank cover kit (130768-01) isn’t just cosmetic— it seals unused slots to prevent debris ingress, doubling module lifespan in dusty refinery environments. For a Louisiana chemical plant, this rack reduced 3500 system downtime by 80% compared to their old generic rack, avoiding $190k in unplanned outages.

Installation & Maintenance Pitfalls (Expert Tips)

- Module Slot Order Is Non-Negotiable: Rookies install monitoring modules in the leftmost slots, which are reserved for power/interface modules. A Michigan steel mill’s 3500 system failed to boot until the 3500/10 power module was moved to the first slot. Always follow the 3500 rack layout: leftmost slots for power/interface modules, monitoring/relay modules to the right.

- Segregate Power & Signal Cables: Routing 24VDC power cables alongside signal cables (e.g., proximity probe wires) induces EMI. A Florida refinery’s vibration data had persistent noise until power cables were routed through a separate conduit. Maintain 15cm minimum separation between power and signal cables in the rack.

- Blank Covers Are Critical (Not Optional): Leaving unused slots uncovered lets dust and moisture enter, corroding backplane pins. A North Carolina paper mill’s rack backplane failed after 18 months due to unprotected slots—install the 130768-01 blank covers immediately, even if you plan to add modules later.

- Ventilation Clearance: 50mm Minimum Rear Space: The rack’s backplane dissipates heat through convection—blocking it with cables or equipment triggers overheating. A Texas chemical plant’s power module shut down during summer until rear clearance was increased to 50mm. Never stack tools or cables against the rack’s rear panel.

- Plan for Expansion: Rookies fill all slots during initial installation, leaving no room for upgrades. A Pennsylvania power plant had to rewire an entire rack to add a 3500/94 communication module—leave 1-2 spare slots for future expansion (e.g., additional monitoring channels or redundancy).

Bently Nevada 3500/05 130768-01

Technical Deep Dive & Overview

The Bently 3500/05 130768-01 is the passive backbone of the 3500 Machinery Protection System, engineered to provide a stable platform for module integration, power distribution, and signal communication. At its core is a precision-machined steel chassis with a passive backplane—no active electronics, which reduces failure points and improves reliability. The backplane features two key functions: distributing 24VDC power from 3500/10 modules to all installed modules, and enabling high-speed data transfer between modules (e.g., from a 3500/42M monitoring module to a 3500/25 relay module).

Keyed module slots prevent misinstallation by only allowing 3500 modules to seat correctly—each module’s connector aligns with the backplane’s power and signal pins, eliminating contact resistance. The 130768-01 blank cover kit seals unused slots, creating a dust-tight barrier that protects the backplane from industrial contaminants. The rack’s steel chassis and anti-vibration mounting points withstand 5g vibration (10-2000Hz), common in turbine and compressor enclosures.

Unlike active racks with built-in electronics, the passive design of the 3500/05 means it has no firmware to update or components to fail—its reliability depends solely on mechanical integrity. This makes it ideal for harsh industrial environments where unplanned downtime is catastrophic. For maintenance teams, this rack isn’t just a housing—it’s a critical infrastructure component that ensures the 3500 system’s modules work in harmony, delivering the reliable monitoring and shutdown capability needed to protect critical rotating assets.