Description

Key Technical Specifications

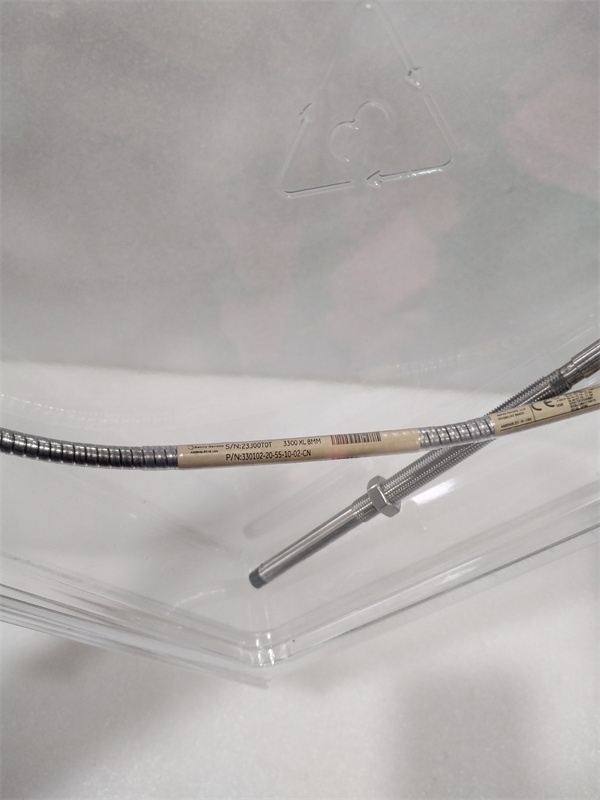

- Model Number: 330102-00-28-05-02-00

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Probe Type: Eddy current (inductive) proximity sensor with integral cable

- Probe Diameter: 5mm (0.197″) – optimized for tight bearing housings

- Case Length: 28mm (1.102″) – ultra-compact for limited-clearance installations

- Unthreaded Length: 0mm – flush-mount capability for shallow bores

- Cable Configuration: 5ft (1.52m) integral cable; PFA (perfluoroalkoxy) insulation, 100% stainless steel braided shield, 22 AWG stranded copper conductors

- Connector Type: MIL-C-5015 male (mates with 3300 XL Proximitors)

- Linear Measurement Range: 2mm (0.079″) peak-to-peak

- Sensitivity: 200 mV/mm (5.08 mV/mil) typical (ferrous target, 25°C)

- Operating Temperature: -54°C to +121°C (-65°F to +250°F)

- Impedance: 50Ω (matched to 3300 XL Proximitor impedance)

- Certifications: CE, ATEX Zone 0 (Ex ia IIC T6), IECEx ia IIC T6, API 670 compliant

- Compatibility: Bently 3300 XL Proximitors, 3500 Machinery Protection System, System 1 Condition Monitoring Software

- Bend Radius: 12mm (static), 20mm (dynamic)

- Weight: 0.3kg (0.66lbs) (including 5ft cable)

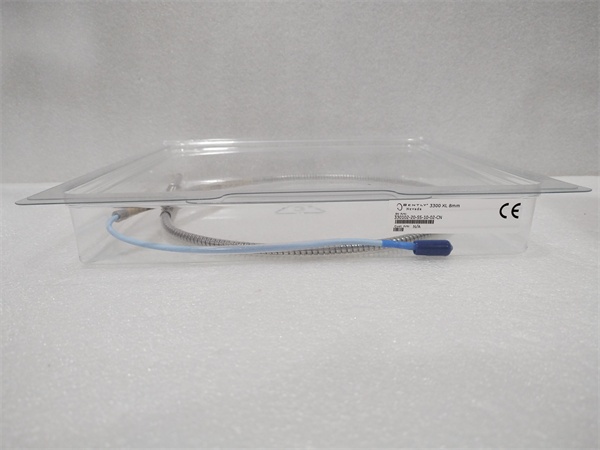

Bently Nevada 330102-00-28-05-02-00

Field Application & Problem Solved

In ultra-compact rotating machinery—refinery precision lube pumps, power plant auxiliary exciters, medical device manufacturing turbines—the biggest probe challenge is fitting a reliable vibration sensor into spaces where even standard 5mm probes with 35mm+ cases won’t fit. Generic 5mm probes fail here: their cases are too long (30mm+), cables use brittle PVC insulation (cracking in high-vibration compact enclosures), or lack impedance matching (causing sensitivity loss over even 5ft runs). A Texas refinery lost $85k in a 2-hour outage when a generic probe’s 32mm case forced improper mounting, leading to inaccurate vibration data and a precision pump bearing failure. A Pennsylvania medical device plant spent $22k annually replacing generic probes with PVC cables that degraded in their cleanroom high-temperature turbines.

This probe solves these issues with its 28mm ultra-compact case and 5ft PFA-shielded cable. You’ll find it in: micro-turbine bearing housings, close-coupled precision pumps, small fan shafts—anywhere space is measured in millimeters but reliable vibration data is critical. It’s the standard for retrofitting legacy compact machinery with 3300/3500 system compatibility, as its flush-mount design (0mm unthreaded length) fits in shallow bores that longer probes can’t access.

Its core value is ultra-compact form factor + short-run signal integrity + harsh-environment durability. Unlike generics, it maintains 200 mV/mm sensitivity over 5ft via 50Ω impedance matching, resists chemicals and temperature swings with PFA insulation, and fits in spaces where even 3mm-case probes (too fragile for industrial use) are the only alternative. For a Louisiana pharmaceutical plant, this probe enabled monitoring of their 20mm-diameter reactor pumps—avoiding $30k in machinery modification costs and eliminating false trips from generic probe misalignment.

Installation & Maintenance Pitfalls (Expert Tips)

- Gap Setting: 1mm Mid-Range Is Non-Negotiable: Rookies set the gap too close (saturating the signal) or too far (losing linearity) in tight spaces. An Ohio steel mill’s micro-turbine monitor showed 0μm displacement until we adjusted the gap to 1mm (midpoint of the 2mm linear range) with a precision feeler gauge. Never guess—use a 0.040″ (1mm) feeler for ferrous targets.

- Connector Torque: 0.8Nm (7.1 in-lbs) – No Exceptions: Over-torquing MIL connectors strips threads; under-torquing causes intermittent signal loss in high-vibration compact machinery. A Florida refinery’s precision pump probe failed after 3 months when the connector was torqued to 1.2Nm—invest in a mini torque wrench for tight spaces.

- Shield Grounding: Single-Point at Proximitor End Only: Grounding the shield at both probe and proximitor creates a ground loop, introducing 60Hz noise. A North Carolina power plant’s auxiliary exciter data had persistent hum until we disconnected the shield from the pump housing and grounded it solely at the proximitor. Never splice the shield—maintain continuity.

- Cable Routing: Avoid Sharp Bends in Compact Spaces: Rookies force the cable into tight bends (≤8mm radius) to fit, cracking the PFA insulation. A Michigan paper mill’s small fan probe shorted after 6 months until we rerouted the cable with 12mm+ bends and used rubber grommets to protect against sharp edges.

- Splicing Is a Failure Point: Rookies splice shorter cables to reach 5ft, doubling impedance. A Texas chemical plant’s probe sensitivity dropped by 30% until we replaced the spliced setup with this integral 5ft model—splicing voids calibration and API 670 compliance.

Bently Nevada 330102-00-28-05-02-00

Technical Deep Dive & Overview

The Bently Nevada 330102-00-28-05-02-00 is a precision-engineered eddy current proximity probe designed for the tightest industrial spaces. At its core, a miniature wound coil in the 5mm probe tip generates a high-frequency electromagnetic field. When a ferrous shaft (target) enters the field, eddy currents are induced in the shaft, altering the coil’s impedance. The integral 5ft cable transmits this impedance change to a 3300 XL Proximitor, which converts it into a linear voltage output (-24V to 0V) proportional to the probe-to-shaft gap—enabling accurate measurement of radial vibration, axial displacement, and eccentricity.

What sets this probe apart is its balance of ultra-compact size and industrial durability. The 28mm case length is 20-30% shorter than standard 5mm probes, fitting in bores and housings where longer models can’t—yet it retains industrial-grade PFA insulation (resistant to lube oil, chemicals, and temperature extremes) and a 100% stainless steel braided shield (blocks EMI/RFI from nearby motors/VFDs). The 50Ω impedance matching ensures no sensitivity loss over the 5ft run—unlike generic compact probes, which often see 15-20% signal degradation at this length.

Unlike generic 5mm probes, it’s API 670 compliant, meeting strict reliability standards for machinery protection. Its flush-mount design (0mm unthreaded length) allows installation in shallow bores, and the MIL-C-5015 connector provides a vibration-resistant connection that won’t loosen in high-vibration compact machinery. For maintenance teams, this probe isn’t just a “small sensor”—it’s a reliable solution for extending 3300/3500 system monitoring to assets that were previously unmonitorable due to space constraints. By providing accurate, noise-free data, it enables early detection of faults like bearing wear or shaft misalignment in critical compact machinery, preventing costly unplanned downtime.