Description

Key Technical Specifications

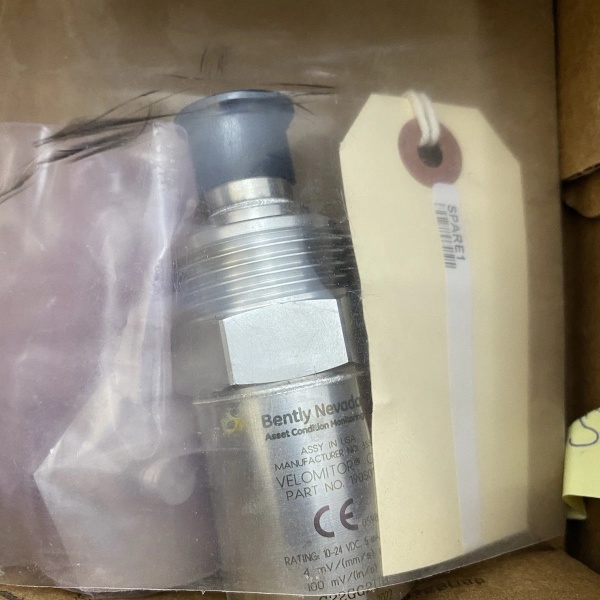

- Model Number: 190501-12-00-04

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Channel Count: 2 independent monitoring channels

- Measurement Parameters: Vibration velocity (RMS) or displacement (peak-peak); configurable per channel

- Measurement Range: Velocity: 0-25mm/s (0-1.0 ips); Displacement: 0-254μm (0-10 mils)

- Input Type: Accepts signals from eddy current proximity probes (3301 series) or accelerometers (IEPE/charge)

- Power Supply: 12VDC ±10% (10.8-13.2VDC); 0.2A typical current draw

- Output Configuration: 2 form C relays (1 per channel) – 5A @ 250VAC / 5A @ 30VDC

- Display: 4-digit LED display (per-channel measurement value + status)

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Mounting Type: Panel-mount (DIN rail or direct bolt-on), IP65 front panel

- Isolation Rating: 500V AC (input circuits to power/output)

- Certifications: CE, UL 508, ATEX Zone 2 (Ex nA IIC T4), IECEx

- Compatibility: Bently 3301 proximity probes, industrial accelerometers, auxiliary pumps/fans/motors

- Diagnostic Capability: LED status indicators (power, channel alarm/trip, fault), relay activation feedback

- Response Time: ≤20ms (alarm/trip trigger)

Field Application & Problem Solved

In auxiliary rotating machinery—refinery lube oil pumps, power plant cooling fans, chemical plant process pumps—the biggest challenge is cost-effective, standalone vibration monitoring. Full rack systems (like 3500 Series) are overkill for small assets, while generic standalone monitors lack ruggedness, accurate measurement, and reliable trip logic. A Texas refinery lost $85k in a 2-hour outage when a generic monitor failed to detect a 20mm/s vibration spike in a lube oil pump, leading to bearing seizure. A Pennsylvania food processing plant spent $15k annually on false trips from monitors that couldn’t filter out motor noise.

This monitor solves these issues by offering Bently’s precision in a compact, standalone package. You’ll find it in: pump skids, fan housings, motor control panels, and remote auxiliary equipment where wiring to a central rack is impractical. It’s the standard for facilities looking to extend predictive maintenance to secondary assets without the cost of a full protection system.

Its core value is standalone functionality + Bently-calibrated accuracy + rugged design. Unlike generics, it uses Bently’s proprietary signal processing to filter noise and accurately measure vibration, while the IP65 front panel withstands washdowns and dust. For a Louisiana water treatment plant, this monitor reduced pump-related downtime by 60% by detecting early bearing wear in their chemical dosing pumps—something generic monitors missed until failure.

Installation & Maintenance Pitfalls (Expert Tips)

- Sensor Type Calibration: Match Input to Configuration: Rookies use accelerometers with the monitor set to “proximity probe” mode, causing incorrect readings. An Ohio steel mill’s fan monitor showed 0mm/s vibration until the input type was adjusted in the menu. Use the front-panel buttons to select “accelerometer” or “proximity” per channel—verify with a calibration signal.

- Power Supply Mismatch: Don’t Use 24VDC for 12VDC Models: The “12” suffix denotes 12VDC—wiring 24VDC fries the internal power supply. A Florida refinery destroyed two units ($900 total) before checking the model label. Use a regulated 12VDC source and confirm voltage with a multimeter before powering on.

- Relay Wiring: Test Trip Logic Post-Installation: Rookies assume relay logic works without verification, leading to failed shutdowns. A Michigan paper mill’s pump didn’t shut down during a high-vibration event because the relay was wired to NC instead of NO. Use a signal generator to simulate a fault and confirm relay activation—document results for safety compliance.

- Display Ignorance: Learn to Interpret LED Codes: Rookies ignore the LED status indicators, missing alarm conditions. A North Carolina power plant’s fan monitor was in “fault” mode for 3 days until a technician recognized the flashing LED—traced to a loose sensor wire. Familiarize yourself with the manual: steady green = normal, flashing amber = alarm, steady red = trip.

- Environmental Protection: Seal Panel Cutouts: The front panel is IP65, but poor panel cutouts let dust/water enter the housing. A Texas chemical plant’s monitor failed after rain seeped through a gap—use the included gasket and torque mounting screws to 1.0Nm for a tight seal.

Technical Deep Dive & Overview

The Bently Nevada 190501-12-00-04 is a standalone vibration monitor engineered to deliver Bently’s precision in a compact, self-contained package. At its core, a 16-bit microprocessor processes signals from accelerometers or proximity probes, converting raw data into calibrated vibration velocity or displacement values. The processor compares these values to user-set alarm/trip thresholds (configurable via front-panel buttons) and activates the corresponding form C relay for shutdown or alert.

Unlike generic monitors, it uses Bently’s proprietary noise-filtering algorithm to eliminate electrical interference from VFDs and motors, ensuring accurate measurements even in noisy environments. The dual-channel design allows monitoring two assets (e.g., a pump and its motor) with one unit, reducing installation costs. The IP65 front panel and wide operating temperature range (-40°C to +70°C) make it suitable for harsh industrial environments, from refinery basements to outdoor fan enclosures.

What sets it apart is its balance of simplicity and performance. It requires no external software or rack system—configuration is done via front-panel buttons, and measurements are displayed in real time on the LED screen. The integral relays eliminate the need for external switching, while the compatibility with Bently’s 3301 probes ensures seamless integration with existing sensor networks. For maintenance teams, this monitor isn’t just a tool—it’s a cost-effective way to extend reliable vibration monitoring to auxiliary assets, preventing unplanned downtime and extending equipment life.