Description

Key Technical Specifications

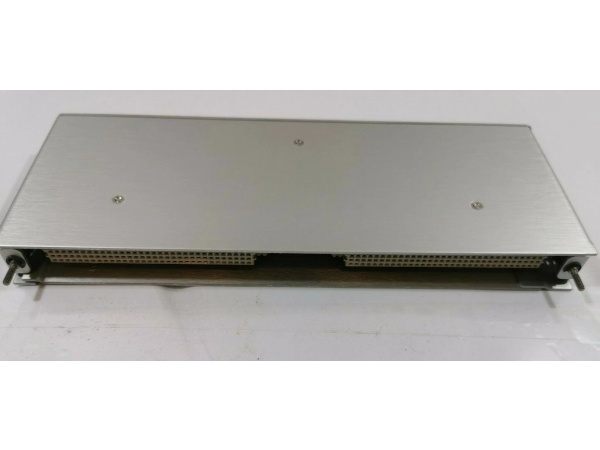

- Model Number: 3500/61-05-01 136711-02

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Channel Count: 6 fully independent temperature channels

- Input Compatibility: RTD (2/3/4-wire Pt100); Thermocouple (J/K/T/E types) – configurable per channel

- Intrinsic Safety Rating: Ex ia IIC T4 (Zone 1/Class I Div 1, Groups A-D)

- Internal Barriers: 250V AC channel-to-channel isolation; eliminates external IS barriers

- Output Signals: 6 isolated 4-20mA recorder outputs (1 per channel); 0-600Ω load resistance

- Power Supply: 24VDC ±10% (19.2-26.4VDC) from 3500 rack backplane; 0.6A typical current draw

- Operating Temperature: -30°C to +65°C (-22°F to +150°F)

- Isolation Rating: 1kV AC (inputs/outputs to backplane/power)

- Certifications: CE, ATEX, IECEx, UL 508, API 670 compliant, SIL 2 (IEC 61508)

- Compatibility: Bently 3500/15 Rack Assembly, 3500/25 Relay Modules, 3500/94 Communication Modules

- Accuracy: ±0.1% of reading (RTD); ±0.2% of reading (TC with cold junction compensation)

- Diagnostic Capability: Per-channel LED indicators (power, signal OK, alarm, fault), open/short circuit detection

Bently 3500/61-05-01 136711-02

Field Application & Problem Solved

In hazardous industrial environments—offshore oil platforms, refineries, chemical plants—the biggest temperature monitoring challenge is reliable, safety-compliant measurement of bearing, lube oil, and winding temps without bulky external intrinsic safety barriers. Generic temp modules fail here: they require separate IS barriers (adding cost and installation complexity), lack 3500 system integration (causing latency), or can’t handle both RTD and TC inputs (forcing multiple modules). An offshore platform in the Gulf of Mexico lost $1.8M in a 12-hour outage when a generic module’s external barrier failed, cutting off compressor bearing temp data and leading to seizure. A Texas refinery spent $45k annually on barrier maintenance and wiring errors from mismatched generic components.

This module solves these issues as a 3500-native system with integrated IS barriers. You’ll find it in Zone 1/Class I Div 1 areas: gas turbine bearing housings, refinery reactor pumps, chemical plant centrifugal compressors—anywhere explosive atmospheres exist and temperature data is critical for safety. It’s mandatory for API 670-compliant systems in hazardous areas, as it meets both machinery protection and explosion safety standards.

Its core value is integrated IS barriers + 3500-native sync + multi-input flexibility. Unlike generics, it eliminates external barriers (cutting installation time by 50%), communicates directly with the 3500 backplane (latency <10ms), and supports RTD/TC on the same module. For a Louisiana chemical plant, this module detected a 20°C bearing temp rise in a Zone 1 compressor 36 hours before failure—avoiding a $320k unplanned shutdown and complying with OSHA hazardous area regulations.

Installation & Maintenance Pitfalls (Expert Tips)

- IS Earthing Module is Mandatory: Rookies skip installing the 3500/04-01 IS Earthing Module, violating hazardous area codes. An Ohio refinery’s safety audit failed until the earthing module was added—this module grounds fault current and maintains IS integrity. Always pair with the 3500/04-01 in the same rack.

- Separate Hazardous/Safe Wiring: Routing IS sensor wires (hazardous) with power cables (safe) causes noise and code violations. A Florida offshore platform’s temp readings were erratic until wires were segregated by 30cm and run in separate conduits. Use blue jacketed IS cables for easy identification.

- Channel Configuration Must Match Sensor Type: Rookies leave channels set to “RTD” when using thermocouples, resulting in invalid readings. A Michigan paper mill’s lube oil temp showed -200°C until channels were reconfigured via 3500 software. Verify each channel’s input type (RTD/TC) before commissioning.

- Terminal Torque: 0.5Nm for Small-Gauge Wires: Over-torquing 22AWG sensor wires strips terminals; under-torquing causes arcing. A North Carolina refinery’s TC channel failed intermittently until terminals were torqued to Bently’s spec. Use a precision torque screwdriver for sensor connections.

- Firmware Compatibility with 3500 Rack: Outdated module firmware (pre-v7.0) causes communication drops with 3500 racks running v8.0+. A Texas chemical plant’s technicians wasted 6 hours troubleshooting until the module was updated via the rack’s USB port. Check Bently’s matrix—mismatched firmware breaks data logging.

Technical Deep Dive & Overview

The Bently 3500/61-05-01 136711-02 is a dual-component system: the 3500/61-05-01 base module handles signal processing, while the 136711-02 I/O module provides integrated intrinsic safety barriers. At its core, a 32-bit microprocessor processes inputs: for RTDs, it applies a constant 1mA current and measures voltage drop (Ohm’s law) to calculate temperature; for thermocouples, it uses built-in cold junction compensation (CJC) to correct ambient temp effects, then converts millivolt signals to temperature.

The 136711-02’s integrated IS barriers limit electrical energy (voltage/current) to safe levels, preventing sparks that could ignite explosive atmospheres—eliminating the need for external barriers. The module’s 3500 backplane integration enables real-time data sync with 3500/25 relay modules for safety shutdowns, while 4-20mA outputs feed data to DCS/SCADA for trending.

What sets it apart is its hazardous area compliance without compromise. It maintains API 670 precision (±0.1% for RTDs) while meeting ATEX/IECEx IS standards, a balance generic modules can’t match. The 6-channel design reduces rack space, and open/short circuit detection alerts operators to sensor failures (preventing false trips). For maintenance teams, this module isn’t just a temp monitor—it’s a safety-compliant, integrated solution that protects personnel and assets in the most dangerous industrial environments.