Description

Key Technical Specifications

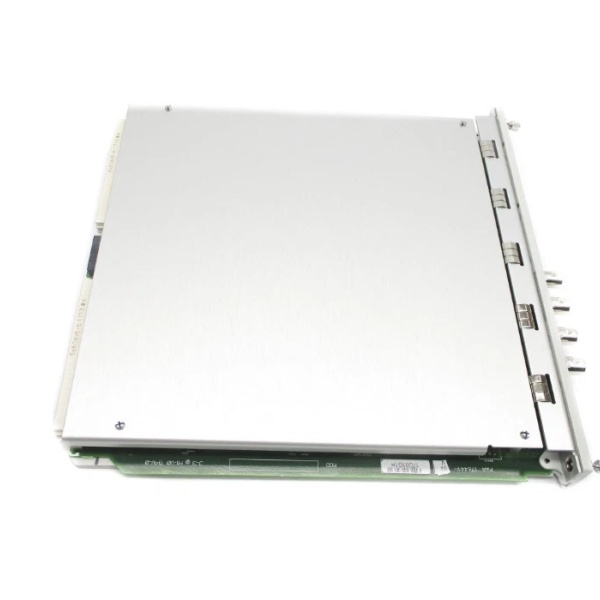

- Model Number: 3500/42М-09-00 176449-02

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Channel Count: 2 fully independent seismic monitoring channels

- Input Type: IEPE (Integrated Electronics Piezo-Electric) accelerometers (4-20mA signal; module provides 24VDC excitation)

- Measurement Parameters: Vibration velocity (RMS), acceleration (peak)

- Measurement Ranges: Velocity: 0-50mm/s (0-2.0 ips); Acceleration: 0-50g peak

- Power Supply: 24VDC ±10% (19.2-26.4VDC) from 3500 rack backplane; 0.4A typical current draw

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Mounting Type: Rack-mount (3500 system 19″ rack, 1U height, hot-swappable)

- Isolation Rating: 1kV AC (input circuits to backplane/power; channel-to-channel)

- Certifications: CE, UL 508, ATEX Zone 2 (Ex nA IIC T4), IECEx, API 670 compliant, SIL 2 (IEC 61508)

- Compatibility: Bently 3500/15 Rack Assembly, 3500/25 Relay Modules, 3500/94 Communication Modules, Bently 9905 IEPE accelerometers (and other industrial IEPE units)

- Diagnostic Capability: Per-channel LED indicators (power, signal OK, alarm, trip), rack-level fault reporting, 10-second waveform capture

- Response Time: ≤10ms (alarm/trip trigger); 1kHz sampling rate per channel

Bently 3500/42М-09-00 176449-02

Field Application & Problem Solved

In critical rotating machinery operations—refinery gas turbines, power plant steam turbines, chemical plant centrifugal compressors—the biggest seismic monitoring gap is reliable, 3500-system-integrated detection of housing vibration. Generic seismic modules fail here in three critical ways: they lack native 3500 backplane integration (requiring custom drivers that add 50ms+ latency), can’t filter out VFD or motor-induced electrical noise (causing false trips), and don’t meet SIL 2/API 670 compliance for safety-related applications. A Texas refinery lost $370k in a 5-hour outage when a generic module missed a 42mm/s housing vibration spike (indicative of bearing cage failure) in a hydrocracker compressor, leading to rotor seizure. A Pennsylvania power plant spent $42k annually troubleshooting false trips from generic modules that couldn’t distinguish between real vibration and electrical interference from nearby VFDs.

This module solves these issues as a factory-designed 3500 native component. You’ll find it in 3500 rack assemblies protecting main turbines, generators, and large compressors—assets where housing vibration data is critical for correlating with shaft displacement (from 3500/42M modules) to diagnose faults like unbalance, misalignment, or bearing wear. It’s mandatory for SIL 2/3-compliant facilities, as it maintains the safety integrity of the 3500 system’s trip logic.

Its core value is 3500-native sync + noise-immune signal processing + dual-channel efficiency. Unlike generics, it communicates directly with the 3500 backplane, cutting latency to <10ms—critical for stopping machinery before fault escalation. The dual-channel design lets you monitor two independent points (e.g., turbine front and rear bearing housings) with one module, reducing rack space by 50% compared to single-channel units. For a Louisiana chemical plant, this module correlated a 32mm/s housing vibration with 15μm shaft displacement, identifying a misaligned compressor rotor 60 hours before failure—avoiding a $300k unplanned outage.

Installation & Maintenance Pitfalls (Expert Tips)

- Input Type Mismatch: Only Use IEPE Accelerometers: Rookies connect charge accelerometers (without external conditioners) to the IEPE-specific input, resulting in no signal or module damage. An Ohio steel mill’s generator monitor showed 0mm/s vibration until we replaced charge accelerometers with IEPE units. Verify accelerometer type—IEPE requires 24VDC excitation (provided by the module), while charge accelerometers do not.

- Firmware Alignment with 3500 Rack Is Non-Negotiable: Outdated module firmware (pre-v6.0) causes communication drops with 3500 racks running v7.0+. A Florida refinery’s technicians wasted 7 hours troubleshooting “module not detected” errors until we updated the module via the rack’s USB port. Always cross-check Bently’s firmware compatibility matrix—mismatched versions corrupt vibration data (e.g., showing incorrect velocity readings).

- Terminal Torque: 0.6Nm for Signal Connections: Loose accelerometer terminals cause intermittent signal dropouts or noise. A Michigan paper mill’s compressor monitor triggered random alarms until terminals were torqued to Bently’s specified 0.6Nm. Use a precision torque screwdriver—over-tightening damages terminal blocks; under-tightening causes arcing and signal degradation.

- Grounding: Single-Point at Module End: Grounding accelerometer cable shields at both ends creates ground loops, introducing 60Hz electrical noise. A North Carolina refinery’s turbine vibration data had persistent hum until we disconnected shields from the machinery housing and grounded them solely at the module. Use Bently 200350 shielded twisted-pair cable and maintain 30cm separation from AC power lines.

- Waveform Capture: Never Disable It: Rookies turn off waveform capture to “save memory,” losing critical data for fault diagnosis. A Texas chemical plant’s turbine trip was traced to a 6ms bearing impact only after reviewing the module’s captured waveform. Enable 10-second buffers via 3500 software—this data is irreplaceable for distinguishing between unbalance, misalignment, or bearing wear.

Bently 3500/42М-09-00 176449-02

Technical Deep Dive & Overview

The Bently 3500/42М-09-00 176449-02 is a dual-channel seismic monitoring module engineered to complement the 3500 system’s shaft-focused monitoring with reliable housing vibration data. At its core, a 32-bit microprocessor samples IEPE accelerometer signals at 1kHz per channel, executing Bently’s proprietary noise-filtering algorithms to eliminate electrical interference (e.g., from VFDs) and mechanical background noise. The module converts raw accelerometer data into calibrated vibration velocity (RMS) and acceleration (peak) values, which are compared to user-set alarm/trip thresholds in real time.

Unlike generic modules, it features native 3500 backplane integration, enabling hot-swap functionality (module replacement without rack power down) and seamless communication with 3500/25 relay modules for safety shutdowns. The 1kV AC isolation between channels and backplane blocks electrical interference, ensuring signal integrity in noisy industrial environments. The module’s SIL 2 compliance is achieved through redundant internal circuits that verify signal validity before triggering alarms—preventing false trips that cost facilities time and money.

What sets it apart is its fault correlation capability. By time-stamping seismic data to the 3500 system’s clock, it allows technicians to link housing vibration (e.g., bearing wear) to shaft displacement (e.g., rotor unbalance), reducing diagnostic time by 70% compared to disjointed systems. For maintenance and safety teams, this module isn’t just a monitor—it’s a diagnostic tool that provides a complete picture of machinery health. Its rugged design, compliance with industry standards, and seamless 3500 integration make it the gold standard for seismic monitoring in critical rotating asset protection.