Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Speed and Keyphasor Monitor |

| Input Channels | 2 channels (speed) + 1 channel (keyphasor) |

| Sensor Compatibility | Magnetic pickup, active proximity probes |

| Frequency Range | 0.1 Hz to 12 kHz (speed), 1 Hz to 12 kHz (keyphasor) |

| Output Signals | 4-20 mA analog, digital (via 3500 system bus) |

| Voltage Supply | 24V DC ±15% |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 17.78 mm (width) × 165.1 mm (height) × 233.68 mm (depth) |

| Certifications | CE, RoHS, ISO 9001 compliant |

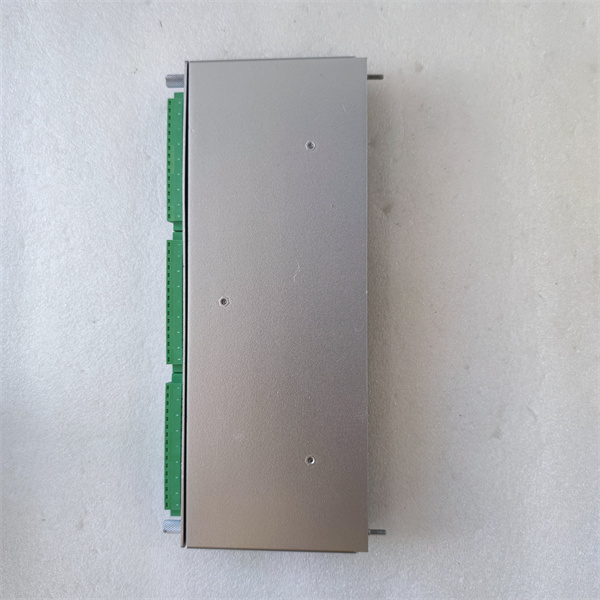

BENTLY 3500/33 149992-01

3. Advantages and Features

4. Application Areas and Case Studies

5. Competitive Comparison

Compared to similar monitoring modules, the BENTLY 3500/33 149992-01 offers superior noise immunity and measurement accuracy, particularly in high-temperature and high-vibration environments. Its robust integration with the 3500 system provides a comprehensive monitoring solution, unlike standalone modules that may require additional hardware or software adjustments. The module’s dual-channel design and advanced diagnostics also offer enhanced functionality, making it a more versatile choice for complex machinery setups where reliability and precision are non-negotiable.

BENTLY 3500/33 149992-01

6. Selection Recommendations

- System Compatibility: Ensure it is compatible with your existing 3500 framework and sensor types (e.g., magnetic pickups or active probes).

- Measurement Requirements: Confirm the frequency range and accuracy meet your machinery’s operational speed and monitoring needs.

- Environmental Conditions: Verify the module’s temperature and vibration resistance align with your site’s industrial environment.

- Redundancy Needs: Evaluate if the dual-channel design is necessary for your application to ensure continuous monitoring and system reliability.

7. Precautions

- Installation: Power down the 3500 system and follow electrostatic discharge (ESD) protocols to avoid damaging the module during installation.

- Sensor Calibration: Regularly calibrate connected sensors to maintain measurement accuracy, following the manufacturer’s guidelines.

- Maintenance: Inspect wiring connections and clean the module periodically to prevent signal interference or mechanical issues.

- Safety Compliance: Adhere to local safety standards when working with high-voltage systems or rotating machinery to ensure operator and equipment safety.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.