Description

Key Technical Specifications

- Model Number: 3500/25-02-01-01

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Channel Count: 4 independent relay channels (per module)

- Contact Type: Form C (changeover) – 1 NO (Normally Open) + 1 NC (Normally Closed) per channel

- Contact Rating: 5A @ 250VAC / 5A @ 30VDC (resistive load)

- Power Supply: 24VDC ±10% (19.2-26.4VDC); 0.3A typical current draw

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Mounting Type: Rack-mount (3500 system 19″ rack, 1U height, hot-swappable)

- Isolation Rating: 1kV AC (control circuits to power contacts)

- Certifications: CE, ATEX Zone 2 (Ex nA IIC T4), IECEx, UL 508

- Compatibility: Bently 3500/15 Rack Assembly, 3500/40 Monitoring Modules, 3500/92 Communication Module, rotating machinery safety systems

- Diagnostic Capability: Per-channel LED indicators (power, energized status), rack-level fault reporting

- Response Time: ≤10ms (relay energization/de-energization)

- Mechanical Life: 10 million operations (min); Electrical Life: 100,000 operations (at rated load)

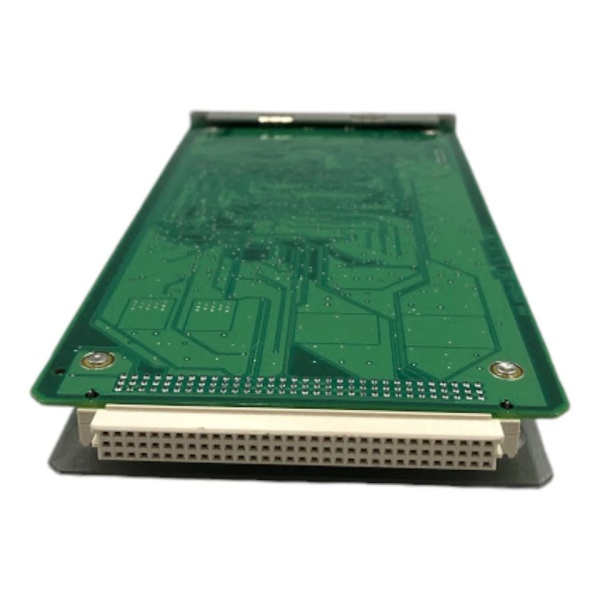

Bently 3500/25-02-01-01

Field Application & Problem Solved

In rotating machinery protection—refinery gas turbines, power plant centrifugal compressors, chemical plant pumps—the biggest challenge is translating electronic alarm/trip signals from monitoring systems into reliable mechanical actions (shutdown valves, emergency stops, alarms). Generic relays fail to integrate with Bently 3500 systems, suffer from contact bounce, or can’t withstand harsh industrial conditions, leading to catastrophic failures or nuisance trips. A Texas refinery lost $420k in a 7-hour outage when a generic relay failed to trigger a turbine shutdown during a high-vibration event, causing bearing damage. A Pennsylvania power plant spent $30k annually troubleshooting false trips from relays that didn’t sync with 3500 monitoring modules.

This module solves these issues by acting as a native interface for the 3500 system. You’ll find it in: 3500 rack assemblies protecting critical rotating assets, turbine control rooms, compressor skid safety panels, and pump station emergency shutdown (ESD) systems. It’s the standard for facilities requiring SIL 2/3 compliance, as it meets IEC 61508 requirements for safety-related systems.

Its core value is 3500-native integration + form C contact flexibility + rugged reliability. Unlike generics, it communicates directly with 3500 monitoring modules (e.g., vibration, displacement) without adapters, eliminating latency. The form C contacts accommodate both shutdown (NO) and alert (NC) logic, while the wide temperature range and vibration resistance (5g @ 10-2000Hz) withstands harsh plant environments. For a Louisiana chemical plant, this relay module reduced false trips by 90% compared to generic units, avoiding 12 hours of annual unplanned downtime.

Installation & Maintenance Pitfalls (Expert Tips)

- Contact Wiring: Match Form C Logic to Safety Requirements: Rookies mix up NO/NC contacts, reversing shutdown/alert logic. An Ohio steel mill’s compressor failed to shut down during a high-displacement event because the relay was wired to NC instead of NO. Use the 3500 Configuration Software to map channels to logic, and verify with a multimeter (energized = NO closes, NC opens).

- Power Supply Mismatch: Never Use AC for 24VDC Modules: The “02” suffix denotes 24VDC—rookies who wire 120VAC fry the module. A Florida refinery destroyed three units ($1,800 total) before checking the model suffix. Always confirm power supply type with the module’s label—use a regulated 24VDC source to avoid voltage spikes.

- Terminal Torque: Tighten to 0.8Nm: Loose terminals cause contact bounce or intermittent failures. A Michigan paper mill’s pump relay triggered random alerts until terminals were torqued to Bently’s specified 0.8Nm. Use a precision torque screwdriver—over-tightening strips terminals; under-tightening causes arcing.

- Hot-Swap Caution: De-Energize Channel First: Rookies hot-swap modules while channels are energized, risking contact welding. A North Carolina power plant’s turbine relay contacts fused after a live swap. Disable the channel via the 3500 software or isolate the power before replacing the module.

- Ignoring LED Diagnostics: Use LEDs for Quick Troubleshooting: Rookies overlook per-channel LEDs, wasting hours on wiring checks. A Texas refinery’s technician spent 3 hours troubleshooting a “no trip” issue until noticing the channel’s LED wasn’t energized—traced to a faulty 3500/40 module. Green = de-energized, red = energized; use LEDs to verify signal flow before deep diagnostics.

Bently 3500/25-02-01-01

Technical Deep Dive & Overview

The Bently 3500/25-02-01-01 is a dedicated relay module engineered to bridge Bently’s 3500 Machinery Protection System with physical safety/alert devices. At its core, each channel features an electromechanical form C relay that responds to digital signals from 3500 monitoring modules (e.g., vibration, axial displacement). When a monitoring module detects a fault (e.g., vibration exceeding 25mm/s), it sends a 24VDC signal to the relay, which energizes—switching NO contacts closed (for shutdowns) and NC contacts open (for silencing alerts).

Unlike generic relays, it’s hot-swappable in the 3500 rack, enabling maintenance without powering down the entire system—critical for 24/7 operations. The module’s 1kV AC isolation blocks electrical interference from VFDs and motor cables, while the form C contacts provide flexibility for dual-purpose logic (e.g., one channel for shutdown, another for HMI alerts). The electromechanical design ensures reliable operation in high-vibration environments, with no software latency or firmware failures.

What sets it apart is its seamless integration with the 3500 ecosystem. It’s configured via the 3500 Configuration Software, allowing technicians to map channels to specific monitoring modules and set delay times (0-60 seconds) to prevent nuisance trips. The per-channel LEDs and rack-level fault reporting provide real-time visibility into relay status, simplifying troubleshooting. For facilities relying on 3500 systems, this module isn’t just a relay—it’s a critical safety component that ensures rotating machinery shuts down or alerts operators when faults occur, preventing catastrophic damage and protecting personnel.