Description

Key Technical Specifications

- Model Number: 3500/25-02-01-00-00

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Relay Configuration: 2 fully independent channels (each configurable for alarm or trip)

- Contact Type/Rating: SPST-NO (Single Pole Single Throw – Normally Open); 5A @ 240VAC / 5A @ 24VDC (resistive load); 1A @ 240VAC (inductive load)

- Power Supply: 24VDC ±10% (19.2-26.4VDC) from 3500 rack backplane; 0.2A typical current draw

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Mounting Type: Rack-mount (3500 system 19″ rack, 1U height, hot-swappable)

- Isolation Rating: 1kV AC (relay outputs to backplane/power; channel-to-channel)

- Certifications: CE, UL 508, ATEX Zone 2 (Ex nA IIC T4), IECEx, SIL 2 (IEC 61508), API 670 compliant

- Compatibility: Bently 3500/15 Rack Assembly, 3500/42M/22M/61 Monitoring Modules, 3500/94 Communication Modules

- Diagnostic Capability: Per-channel LED indicators (power, ready, alarm/trip, bypass, fault), rack-level fault reporting, relay contact wear monitoring

- Response Time: ≤5ms (relay actuation from 3500 trip signal)

- Firmware Requirement: 3500 system firmware v6.0+ (must align with rack controller)

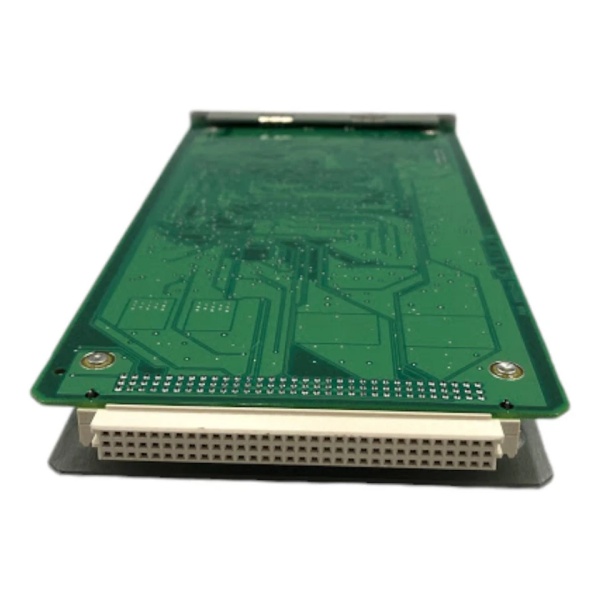

- Dimensions: 483mm W × 44mm H × 242mm D (19″ × 1U × 9.5″); Weight: 0.7kg (1.54lbs)

3500/25-02-01-00-00

Field Application & Problem Solved

In critical rotating machinery safety—refinery gas turbines, power plant steam turbines, chemical plant centrifugal compressors—the biggest challenge is reliable dual-channel shutdowns for interdependent faults (e.g., high vibration + bearing overtemp) without latency or false trips. Generic 2-channel relays fail here: they lack native 3500 backplane integration (requiring hardwired connections that add 50ms+ latency), can’t sync with 3500 fault data (complicating root-cause analysis), and don’t meet SIL 2/API 670 standards for safety-critical applications. A Texas refinery lost $320k in a 4-hour outage when a generic relay delayed a shutdown by 180ms after a 3500/42M detected rotor rub, leading to turbine damage. A Pennsylvania power plant spent $38k annually troubleshooting false trips from generic relays that couldn’t filter VFD-induced electrical noise.

This module solves these issues as the factory-designed 2-channel relay for 3500 systems. You’ll find it in 3500 rack assemblies protecting main turbines, generators, and large compressors—assets where two independent fault triggers (e.g., radial vibration + lube oil temp) require fast, coordinated shutdowns. It’s mandatory for SIL 2/3-compliant facilities, as it maintains the safety integrity of the 3500 system’s trip logic while optimizing rack space (1U for two channels).

Its core value is 3500-native sync + dual-channel efficiency + SIL 2 reliability. Unlike generics, it communicates directly with the 3500 backplane (latency ≤5ms), allows independent configuration of each channel (alarm/trip), and logs actuation events with time-stamps linked to 3500 monitoring data. For a Louisiana chemical plant, this module triggered a compressor shutdown within 6ms of simultaneous high vibration and bearing temp faults—avoiding $270k in unplanned downtime and complying with API 670 requirements.

Installation & Maintenance Pitfalls (Expert Tips)

- Overloading Contacts Destroys Reliability: Rookies use the 5A contacts to switch 6A motor starters or 3A inductive loads, welding contacts and causing delayed shutdowns. An Ohio steel mill’s turbine failed to trip because a relay contact was fused—always derate for inductive loads (1A max) and verify load specs against Bently’s datasheet. Use contactors for loads exceeding 5A resistive.

- Firmware Mismatch Breaks Trip Signal Flow: Outdated module firmware (pre-v7.0) causes “signal not received” faults with 3500 racks running v8.0+. A Florida refinery’s technicians wasted 6 hours troubleshooting until we updated the module via the rack’s USB port. Cross-check Bently’s firmware matrix—mismatched versions block communication between monitoring modules and the relay.

- Terminal Torque: 0.6Nm (5.3 in-lbs) Is Non-Negotiable: Loose terminals cause intermittent actuation; over-torquing strips terminal blocks. A Michigan paper mill’s compressor relay triggered random alarms until terminals were torqued to spec. Use a precision torque screwdriver for 18-22 AWG wiring—no “hand-tight” shortcuts.

- Bypass Mode Is a Safety Hazard: Rookies enable bypass to test wiring and forget to reset it, leaving machinery unprotected. A North Carolina refinery’s turbine ran unprotected for 3 days until a safety audit—always confirm the “bypass” LED is off before commissioning, and install a physical lock on the bypass switch in production.

- Wiring Segregation Prevents Noise-Induced False Trips: Routing 24VDC trip wires alongside 480V power cables induces noise. A Texas chemical plant’s relay tripped randomly until trip wires were rerouted through shielded conduit with 30cm separation from power cables. Use twisted-pair shielded cable and ground shields at the module end only.

- Monitor Contact Wear for Preventive Maintenance: Relay contacts degrade over time (typically 100k+ cycles). A Louisiana refinery’s relay failed to actuate after 5 years of heavy use—use 3500 software to log contact actuation cycles, and replace the module at 80% of Bently’s rated cycle life (80k cycles for this model).

3500/25-02-01-00-00

Technical Deep Dive & Overview

The Bently 3500/25-02-01-00-00 is a 2-channel safety relay module engineered to act as the final link in the 3500 Machinery Protection System’s safety chain. At its core, a dedicated 32-bit microprocessor receives fault commands from 3500 monitoring modules (e.g., 3500/42M vibration, 3500/61 temperature) via the rack backplane. It validates each signal (filtering electrical noise and transient spikes) and actuates the corresponding SPST-NO relay within ≤5ms—fast enough to stop rotating machinery before faults escalate to catastrophic damage (e.g., rotor seizure, bearing failure).

Unlike generic relays, its 3500-native integration ensures seamless sync with the entire system: each channel can be independently configured via 3500 software (e.g., Channel 1 = “high vibration trip,” Channel 2 = “high temp alarm”), and actuation events are time-stamped to the 3500 system clock for root-cause analysis. The hot-swappable design allows module replacement without powering down the 3500 rack—critical for 24/7 operations where downtime is costly.

What sets it apart is its SIL 2-compliant fault-tolerant design. Redundant internal circuits verify relay actuation, ensuring no single component failure prevents a shutdown. The 1kV AC isolation between channels and backplane blocks interference from VFDs, motor cables, and industrial equipment—eliminating false trips that plague generic relays. The 2-channel form factor optimizes rack space, replacing two single-channel modules with one 1U unit while maintaining independent control of dual fault triggers.

For maintenance and safety teams, this module isn’t just a relay—it’s a reliable, compliant solution that translates 3500 monitoring data into actionable safety responses. Its rugged design, seamless 3500 integration, and adherence to industry standards make it the gold standard for dual-channel safety shutdowns in critical rotating machinery.