Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/05-01-03-00-00-00 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Communication Module |

| Communication protocols | Modbus RTU, Modbus TCP/IP, Ethernet/IP |

| Data transfer rate | Up to 100 Mbps (Ethernet), 115.2 kbps (serial) |

| Channel configuration | 1 Ethernet port, 2 serial ports |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15 106M1079-01 power supply) |

| Power consumption | 5 W typical, 7 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

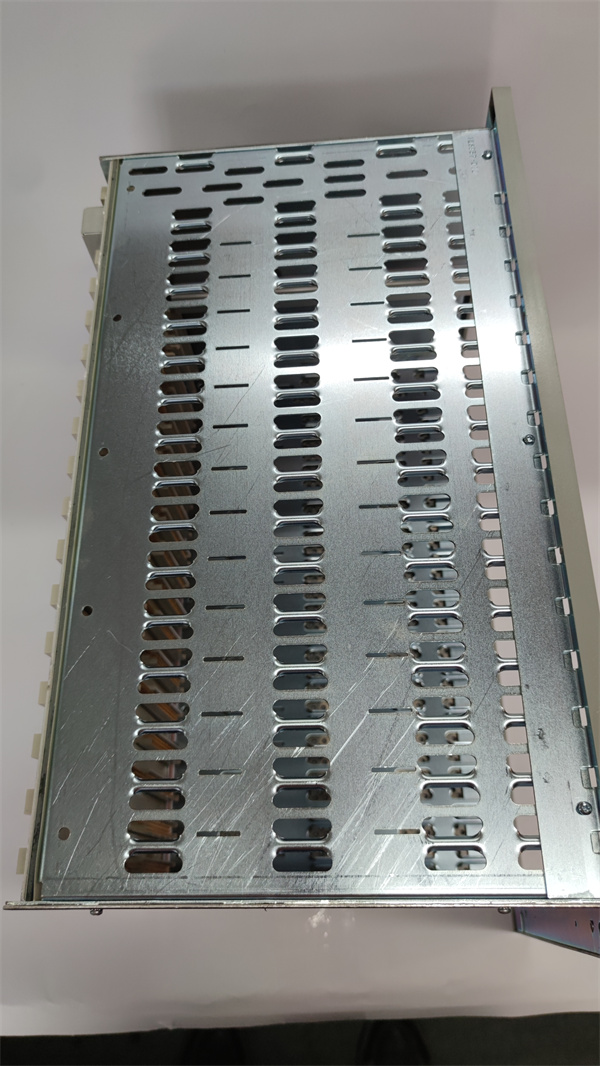

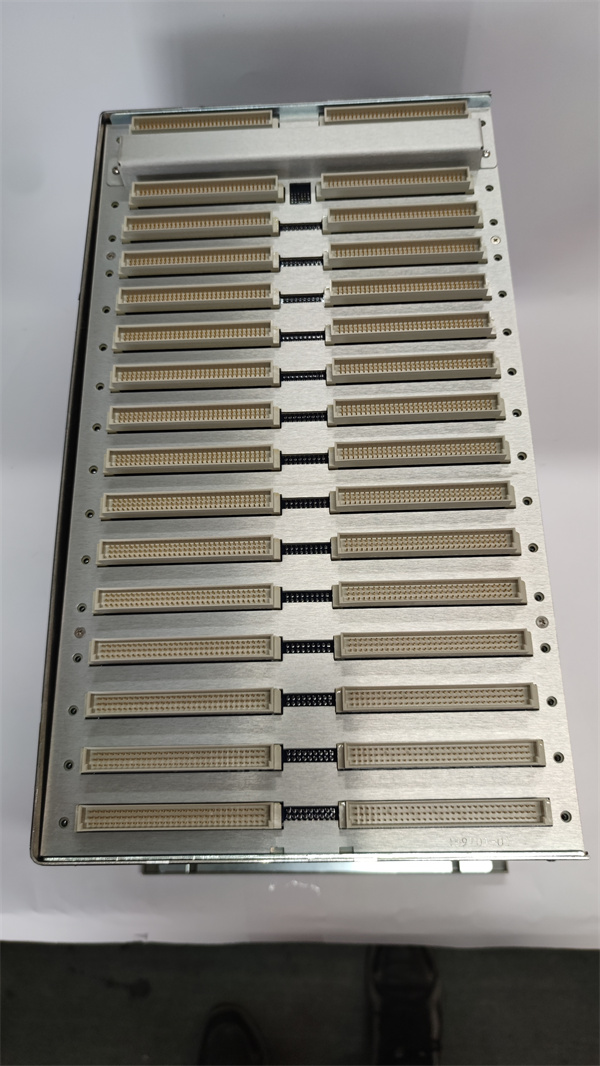

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 72 mm (W) × 229 mm (D) (5.2″ × 2.8″ × 9.0″) |

| Compatibility | 125744-02 racks, 3500/44M 176449-03 monitors, SCADA systems |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 3500/05-01-03-00-00-00

Product introduction

The 3500/05-01-03-00-00-00 from Bently Nevada is a critical communication gateway in the 3500 Machinery Protection System, serving as the primary interface between monitoring modules and enterprise-level systems. This 1-slot module enables seamless data transmission from measurement components like the 3500/44M 176449-03 to plant control systems, SCADA platforms, and asset management software. As the communication backbone of 3500 systems, 3500/05-01-03-00-00-00 ensures that critical machinery health data—including vibration, position, and temperature measurements—flows reliably across industrial networks.

Bently Nevada’s 3500/05-01-03-00-00-00 consolidates data from connected 3500 modules, converts it into industry-standard protocols, and distributes it to authorized systems. Installed in 125744-02 racks and powered by 3500/15 106M1079-01 supplies, it acts as a secure data hub that maintains measurement integrity while enabling remote monitoring and analysis. This module is essential in modern industrial environments where integrated data systems drive both real-time protection and predictive maintenance strategies.

Core advantages and technical highlights

Multi-protocol support: A key feature of 3500/05-01-03-00-00-00 is its support for multiple industrial communication protocols, including Modbus RTU, Modbus TCP/IP, and Ethernet/IP. This versatility allows seamless integration with diverse control systems and enterprise platforms, eliminating the need for custom interface solutions when connecting 3500/44M 176449-03 and other monitoring modules to plant-wide networks.

High-speed data transmission: The module delivers data transfer rates up to 100 Mbps over Ethernet, ensuring timely delivery of critical measurements from 3500/44M 176449-03 modules. This speed is particularly important for transmitting transient data captures and alarm events, where real-time visibility can prevent machinery damage or unplanned downtime.

Reliable data aggregation: 3500/05-01-03-00-00-00 consolidates data from multiple 3500 modules into a unified stream, maintaining time synchronization and measurement correlation. This aggregation simplifies data analysis by preserving relationships between parameters—such as the link between temperature spikes and vibration increases monitored by 3500/44M 176449-03—ensuring accurate diagnostic insights.

Secure communication: The module includes built-in security features such as access controls, data encryption, and protocol filtering to protect sensitive machinery data. This security is critical in modern industrial networks, preventing unauthorized access to protection system data while ensuring compliance with industry cybersecurity standards.

Typical application scenarios

Power plant asset management

In power generation facilities, 3500/05-01-03-00-00-00 modules serve as the communication bridge between turbine monitoring systems and enterprise asset management platforms. They collect correlated vibration, position, and temperature data from 3500/44M 176449-03 modules monitoring turbine bearings, convert it to Modbus TCP/IP, and transmit it to centralized maintenance systems. This integration enables plant engineers to analyze long-term trends, schedule predictive maintenance, and receive real-time alerts when turbine conditions approach alarm thresholds.

Oil and gas pipeline monitoring

Remote pipeline compressor stations utilize 3500/05-01-03-00-00-00 to connect 3500/44M 176449-03 monitors to SCADA systems via Ethernet/IP. The module transmits compressor vibration and temperature data across wide-area networks, allowing central control rooms to monitor equipment health at dispersed locations. In this application, the module’s robust communication ensures continuous data flow even in remote areas with challenging network conditions.

Manufacturing plant integration

In large manufacturing complexes, 3500/05-01-03-00-00-00 modules integrate multiple 3500/44M 176449-03 monitoring systems into the plant’s MES (Manufacturing Execution System). Using Modbus RTU, they transmit motor and gearbox health data to production dashboards, enabling operators to correlate machinery condition with production output. This integration helps optimize production schedules by aligning maintenance activities with planned downtime.

BENTLY 3500/05-01-03-00-00-00

Related model recommendations

3500/44M 176449-03: Multi-parameter monitor providing data to 3500/05-01-03-00-00-00.

3500/15 106M1079-01: Power supply module providing regulated power to the communication module.

125744-02: Rack assembly housing the communication module and associated components.

136180-01: Configuration module for programming communication parameters.

3500/60 163179-01: Display module receiving data via 3500/05-01-03-00-00-00.

133388-01: Transient monitor whose data is transmitted through the communication gateway.

123M4610: USB cable for local configuration of communication settings.

Installation, commissioning and maintenance instructions

Installation

Install 3500/05-01-03-00-00-00 in a 125744-02 rack with a properly configured 3500/15 106M1079-01 power supply. Ensure a 1-slot position is available, typically near the top of the rack for easy network access. Connect the module to the rack backplane to establish communication with monitoring modules like 3500/44M 176449-03. Wire Ethernet cables to the network switch using shielded Cat5e or higher cabling, and connect serial devices if using Modbus RTU. Secure all connections with appropriate torque to prevent vibration-induced loosening.

Commissioning

After installation, configure the module using 136180-01 tools or via USB connection with 123M4610 cables. Set network parameters (IP address, subnet mask, gateway) to match plant network requirements. Configure protocol settings (Modbus register mapping, Ethernet/IP assembly instances) to ensure compatibility with target systems. Establish data points to be transmitted, including critical parameters from 3500/44M 176449-03 like vibration levels and temperature readings. Test communication links by verifying data reception at target systems and confirming time synchronization across the network.

Maintenance

Include 3500/05-01-03-00-00-00 in quarterly network inspections, verifying Ethernet link status and serial communication integrity. Check status indicators to ensure proper power (from 3500/15 106M1079-01) and data flow. Monitor network performance metrics to identify potential bottlenecks affecting data transmission from 3500/44M 176449-03 modules. Update firmware during scheduled system upgrades to maintain protocol compatibility and security. Clean Ethernet ports annually with approved contact cleaner and inspect cabling for damage during routine rack maintenance.

Service and guarantee commitment

Bently Nevada provides the 3500/05-01-03-00-00-00 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including communication reliability, protocol functionality, and component durability when powered by compatible supplies like 3500/15 106M1079-01. Our technical support team offers expert guidance on network configuration, protocol integration, and troubleshooting data transmission issues between this module and systems like 3500/44M 176449-03.

We offer specialized training on communication architecture design, protocol configuration, and network security specific to 3500/05-01-03-00-00-00. Beyond the warranty period, our service agreements include performance verification, technical support, and expedited replacement services to minimize communication downtime. Bently Nevada’s commitment to quality ensures reliable data transmission throughout the module’s operational lifecycle, backed by our global network of service professionals.