Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 3500/05-01-01-00-00-01 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Communication Module |

| Communication protocols | Modbus RTU, RS-485 |

| Data transfer rate | Up to 115.2 kbps (serial) |

| Channel configuration | 2 RS-485 serial ports |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15 106M1079-01 power supply) |

| Power consumption | 4 W typical, 6 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

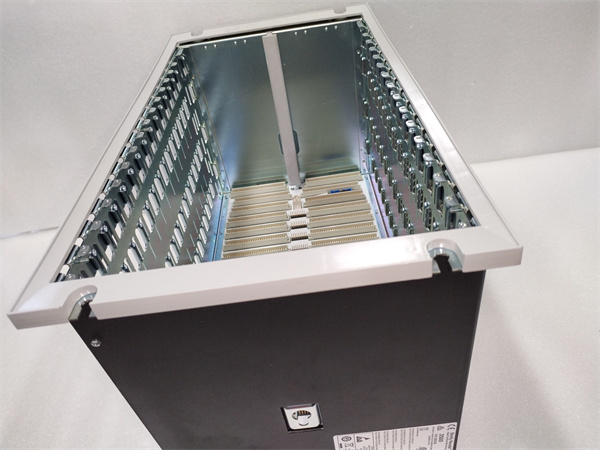

| Form factor | 3500 system rack mount (1 slot width) |

| Dimensions | 133 mm (H) × 72 mm (W) × 229 mm (D) (5.2″ × 2.8″ × 9.0″) |

| Compatibility | 133819-02 cables, 3500/40M 140734-01 modules, 3500 racks |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

| Application | Serial data transmission between monitoring modules and control systems

Product introduction |

BENTLY 3500/05-01-01-00-00-01

The 3500/05-01-01-00-00-01 from Bently Nevada is a specialized serial communication module in the 3500 Machinery Protection System, engineered to facilitate reliable data transmission between monitoring components and industrial control systems. This 1-slot module focuses on Modbus RTU protocol over RS-485, serving as a critical gateway for translating machinery health data into a format compatible with legacy and modern control platforms.

As a protocol-specific communication solution, 3500/05-01-01-00-00-01 connects seamlessly to monitoring modules like the 3500/40M 140734-01, collecting vibration, position, and temperature data from sensors linked via cables such as 133819-02. It consolidates this information into structured Modbus data tables, enabling efficient communication with SCADA systems, PLCs, and asset management software.

In industrial automation ecosystems, 3500/05-01-01-00-00-01 plays a vital role in bridging machinery protection systems with broader operational infrastructure. By ensuring timely and accurate data flow, it supports both real-time decision-making and historical analysis, enhancing overall plant efficiency and machinery reliability across power generation, oil and gas, and manufacturing sectors.

Core advantages and technical highlights

Modbus RTU optimization: 3500/05-01-01-00-00-01 is specifically engineered for Modbus RTU communication over RS-485, delivering optimized data framing and error checking that ensures reliable transmission of critical machinery data. This focus eliminates protocol overhead associated with multi-protocol modules, reducing latency when transmitting time-sensitive alarm information from monitoring systems.

Robust serial communication: The module features isolated RS-485 ports with surge protection (2500V isolation) that safeguards against electrical noise and transient voltage spikes common in industrial environments. This protection is particularly valuable when communicating with systems connected to field sensors via cables like 133819-02, ensuring data integrity even in noisy electrical environments.

Extended communication range: Supporting RS-485 communication distances up to 1200 meters (4000 feet) at lower baud rates, 3500/05-01-01-00-00-01 enables flexible system architecture where control rooms may be remotely located from machinery. This range eliminates the need for expensive fiber optic extensions in many applications, reducing installation costs while maintaining reliable communication.

Seamless system synchronization: The module maintains precise data timestamping and synchronization with connected 3500/40M 140734-01 monitoring modules, ensuring that alarm events and measurement data correlate accurately with process variables in the control system. This synchronization is critical for root cause analysis, allowing engineers to align machinery health data with operational changes.

Typical application scenarios

In power generation facilities, 3500/05-01-01-00-00-01 modules connect turbine vibration monitoring systems to plant SCADA via Modbus RTU. They transmit critical data from 3500/40M 140734-01 modules—fed by sensors linked through 133819-02 cables—including bearing vibration levels, shaft position, and temperature readings. This allows operators to monitor turbine health alongside other plant parameters, enabling coordinated decision-making during normal operation and fault conditions.

Oil and gas pipeline compressor stations utilize 3500/05-01-01-00-00-01 to integrate machinery protection data into pipeline control systems. The module communicates compressor vibration and thrust position data to PLCs, which use this information to adjust operating parameters or initiate shutdowns when abnormal conditions are detected. The RS-485 interface’s long-range capability allows centralized monitoring of multiple compressor stations from a remote control center.

Manufacturing plants employ 3500/05-01-01-00-00-01 to connect motor and pump monitoring systems to factory MES platforms. By translating vibration and bearing temperature data into Modbus registers, the module enables production managers to correlate machinery health with production output, scheduling maintenance during planned downtime rather than experiencing unplanned production stoppages. The module’s robust communication ensures reliable data flow even in electrically noisy factory environments.

BENTLY 3500/05-01-01-00-00-01

Related model recommendations

3500/40M 140734-01: Monitoring module whose data is transmitted by 3500/05-01-01-00-00-01 to control systems.

133819-02: Interface cable connecting sensors to monitoring modules that feed data to this communication module.

3500/15 106M1079-01: Power supply module providing regulated power to 3500/05-01-01-00-00-01.

330106-05-30-10-02-00: Proximity probe system whose measurements are communicated via this module.

3500/25 184684-01: Relay module whose status is reported through 3500/05-01-01-00-00-01.

3500/22M: Transient data module that shares information with this communication gateway.

133323-01: Extension cable compatible with sensor networks feeding data to this module.

3500/60 163179-01: Display module receiving status updates via 3500/05-01-01-00-00-01.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 3500/05-01-01-00-00-01, verify the 3500 rack has a properly functioning 3500/15 106M1079-01 power supply. Prepare RS-485 communication cables with twisted-pair construction and proper shielding to minimize noise. Ensure the installation location provides adequate ventilation and maintains temperature within 0°C to +60°C. Plan cable routes away from high-voltage equipment and motor leads to prevent electromagnetic interference with the module’s serial communication.

Maintenance suggestions: Include 3500/05-01-01-00-00-01 in quarterly communication system checks, verifying RS-485 bus integrity using a Modbus scanner tool. Inspect serial connectors for corrosion or loose pins, cleaning contacts with approved electronic cleaner if necessary. Monitor communication error logs to detect increasing packet loss or retries, which may indicate cable degradation or termination issues. During scheduled maintenance, update module firmware to ensure compatibility with connected systems. Replace the module if communication failures persist after troubleshooting cabling and termination points.

Service and guarantee commitment

Bently Nevada provides the 3500/05-01-01-00-00-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including communication reliability, protocol implementation, and component durability when powered by compatible supplies like 3500/15 106M1079-01. Our technical support team offers expert guidance on Modbus configuration, network design, and troubleshooting interactions with monitoring modules and sensors.

We offer specialized training on RS-485 network design, Modbus protocol implementation, and system integration specific to 3500/05-01-01-00-00-01. Beyond the warranty period, our service agreements include communication network testing, firmware updates, and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures reliable data transmission throughout the module’s operational lifecycle, backed by our global network of service professionals.