Description

Detailed parameter table

| Parameter name | Parameter value |

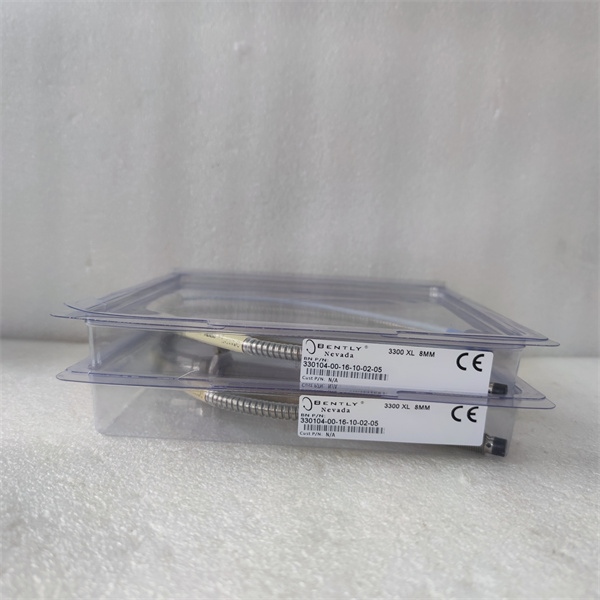

| Product model | 330104-00-05-10-02-00 |

| Manufacturer | Bently Nevada |

| Product category | Proximitor Sensor Extension Cable |

| Series affiliation | 3300 XL Proximitor Sensor System |

| Cable length | 5 meters (16.4 feet) |

| Connector type | Micro-D 15-pin male to Micro-D 15-pin female |

| Cable construction | Shielded twisted-pair conductors |

| Conductor gauge | 22 AWG |

| Operating temperature | -51°C to +149°C (-60°F to +300°F) |

| Vibration resistance | 10 g peak from 10 to 2000 Hz |

| Flex life | 1,000,000 cycles minimum at 25 mm (1 inch) bend radius |

| Protection rating | IP67 when mated with compatible connectors |

| Configuration code breakdown | 00 (base model), 05 (length code), 10 (connector type), 02 (sheath material) |

| Compatibility | 330180 series sensors, 330100-90-01 housings, 3300 XL monitors |

| Certification | Compliant with CE, RoHS, and API 670 standards |

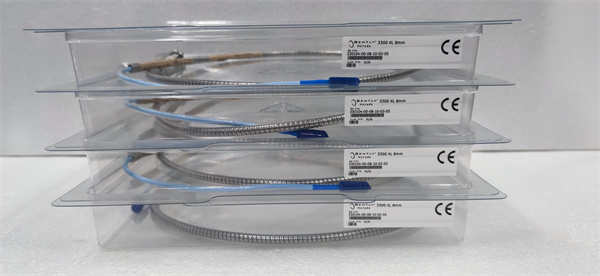

BENTLY 330104-00-05-10-02-00

Product introduction

The 330104-00-05-10-02-00 from Bently Nevada is a high-performance extension cable specifically engineered for the 3300 XL Proximitor Sensor System, serving as a critical link between proximity sensors and monitoring equipment. This precision cable ensures reliable transmission of low-level sensor signals over a 5-meter distance, maintaining signal integrity even in harsh industrial environments. Bently Nevada’s 330104-00-05-10-02-00 is designed to work seamlessly with 330100-90-01 sensor housings and 330180 series proximity sensors, forming an essential component of accurate machinery vibration and position monitoring systems.

Bently Nevada’s 330104-00-05-10-02-00 addresses the challenges of signal transmission in industrial settings where electromagnetic interference and environmental hazards can compromise measurement accuracy. Its shielded, twisted-pair construction minimizes noise pickup, while its rugged design withstands extreme temperatures, vibration, and mechanical stress. This extension cable plays a vital role in ensuring that calibration accuracy achieved with tools like the 330130-085-00-00 is preserved through the entire signal path, delivering reliable data to monitoring systems and HMI interfaces.

Core advantages and technical highlights

Signal integrity preservation: The 330104-00-05-10-02-00 features shielded twisted-pair construction that effectively rejects electromagnetic interference (EMI) and radio frequency interference (RFI) common in industrial environments. This design ensures that weak proximity sensor signals remain unaffected by nearby power cables, motors, or variable frequency drives, maintaining the measurement accuracy established during calibration with the 330130-085-00-00.

Extreme environment performance: With an operating temperature range of -51°C to +149°C, the 330104-00-05-10-02-00 delivers reliable performance in the most demanding industrial conditions. Its rugged jacket material resists oil, chemicals, and abrasion, making it suitable for installation in turbine enclosures, compressor rooms, and other harsh environments where sensor cables are exposed to harsh substances or physical wear.

Precision connectivity: Equipped with Micro-D 15-pin connectors, the 330104-00-05-10-02-00 ensures secure, low-impedance connections between sensors and monitoring equipment. The connectors feature gold-plated contacts that resist corrosion and ensure consistent electrical performance over time, preventing signal degradation that could lead to measurement errors or system instability.

System compatibility: Designed specifically for the 3300 XL system, the 330104-00-05-10-02-00 maintains impedance matching with 330100-90-01 housings and 330180 series sensors. This electrical compatibility is critical for preserving measurement accuracy, ensuring that the calibration data from the 330130-085-00-00 remains valid through the entire signal chain to monitoring systems like the 1900/27.

Typical application scenarios

In power generation facilities, the 330104-00-05-10-02-00 connects proximity sensors mounted on turbine shafts (housed in 330100-90-01 enclosures) to monitoring systems located in control rooms or equipment cabinets. Its ability to transmit signals accurately over 5 meters allows flexible sensor placement while maintaining measurement integrity, essential for monitoring shaft vibration and position in steam and gas turbines. The cable’s high-temperature rating makes it suitable for installation in turbine compartments where ambient temperatures can reach extreme levels.

Oil and gas processing plants utilize the 330104-00-05-10-02-00 to connect sensors on compressors and pumps to local monitoring panels. Its EMI-resistant design ensures reliable signal transmission in environments with high electrical noise from motor controls and variable frequency drives. The cable’s rugged construction withstands exposure to hydrocarbon vapors and industrial cleaning agents, maintaining performance in refineries, offshore platforms, and pipeline compressor stations.

Manufacturing facilities deploy the 330104-00-05-10-02-00 in production line machinery monitoring, connecting sensors on motors, gearboxes, and spindles to centralized monitoring systems. Its flexibility and durability allow installation in tight spaces and robotic cells, where cables may be subject to continuous movement or mechanical stress. The cable ensures that vibration data used by the 1900/55-0Z-01-01-01 HMI remains accurate, supporting predictive maintenance programs and reducing unplanned downtime.

BENTLY 330104-00-05-10-02-00

Related model recommendations

330180-90-01 (Bently Nevada): Proximity sensor directly connected to the 330104-00-05-10-02-00 cable.

330100-90-01 (Bently Nevada): Sensor housing compatible with the 330104-00-05-10-02-00 extension cable.

330130-085-00-00 (Bently Nevada): Calibration fixture used to verify sensors connected via 330104-00-05-10-02-00.

1900/27 (Bently Nevada): Controller that receives signals transmitted through the 330104-00-05-10-02-00.

133819-01 (Bently Nevada): Signal conditioner connected via 330104-00-05-10-02-00 in extended systems.

330104-00-10-10-02-00 (Bently Nevada): 10-meter variant of the 330104-00-05-10-02-00 for longer distance applications.

330106-00-05-10-02-00 (Bently Nevada): Right-angle connector version of the 330104-00-05-10-02-00 for tight installations.

60M100-00 (Bently Nevada): Display unit that visualizes data transmitted through the 330104-00-05-10-02-00.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 330104-00-05-10-02-00, verify that the cable length matches installation requirements and that connectors are compatible with the target sensor (typically with 330100-90-01 housing) and monitoring equipment. Required tools include connector torque wrenches, cable ties, and appropriate routing hardware. Inspect the cable for shipping damage, checking for cuts in the jacket, connector bent pins, or shield damage. Ensure routing paths avoid sharp edges, excessive heat sources, and high-voltage cables to prevent signal interference or physical damage.

Maintenance suggestions: To maintain optimal performance of the 330104-00-05-10-02-00, conduct semi-annual visual inspections to check for cable jacket damage, connector corrosion, or excessive bending. Verify that connectors remain securely fastened with proper torque. Avoid bending the cable beyond its minimum bend radius or subjecting it to continuous flexing beyond specified limits. During sensor recalibration with the 330130-085-00-00, check for signal degradation by comparing measurements with and without the extension cable. If intermittent signal issues occur, clean connector contacts with approved electrical contact cleaner and verify shield continuity.

Service and guarantee commitment

Bently Nevada provides the 330104-00-05-10-02-00 with a 24-month warranty covering manufacturing defects and material failures, ensuring reliable signal transmission performance under normal operating conditions. Our technical support team offers expert guidance on proper installation techniques, routing practices, and compatibility verification with 330100-90-01 housings and other system components.

We offer specialized training on cable handling and maintenance best practices for the 330104-00-05-10-02-00, ensuring your technicians can maximize cable service life. Beyond the warranty period, our service agreements include cable testing services to verify signal integrity and recommend replacement when degradation is detected. Bently Nevada’s commitment to quality ensures the 330104-00-05-10-02-00 delivers reliable signal transmission throughout its operational lifecycle, backed by our global network of service professionals.