Description

Key Technical Specifications

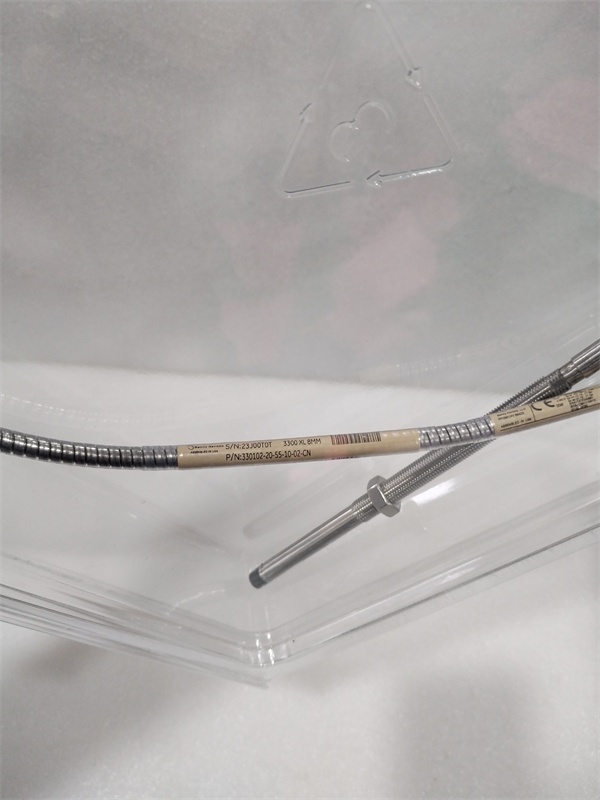

- Model Number: 330102-00-72-10-02-05

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Probe Type: Eddy current (inductive) proximity probe with integral cable

- Probe Diameter: 5mm (0.197″) – optimized for small machinery/bearing housings

- Case Length: 72mm (2.83″) – extended for deep mounting in compact enclosures

- Cable Length: 10ft (3.05m) – mid-range for balanced reach vs signal integrity

- Cable Construction: PFA (perfluoroalkoxy) insulation, 100% stainless steel braided shield, 22 AWG stranded copper conductors

- Connector Type: MIL-C-5015 male (mates with 3300 XL Proximitors)

- Linear Measurement Range: 2mm (0.079″) peak-peak

- Sensitivity: 200 mV/mm (5.08 mV/mil) typical (ferrous target, 25°C)

- Operating Temperature: -54°C to +121°C (-65°F to +250°F)

- Isolation Rating: 500V AC (conductor to shield)

- Impedance: 50Ω (matched to 3300 XL Proximitor impedance)

- Certifications: CE, ATEX Zone 0 (Ex ia IIC T6), IECEx ia IIC T6, API 670 compliant

- Compatibility: Bently 3300 XL Proximitors, 3500 Machinery Protection System, 3300 Series monitoring modules

- Bend Radius: 12mm (static), 20mm (dynamic)

- Weight: 0.5kg (1.1lbs) (including 10ft cable)

-

Bently 330102-00-72-10-02-05

Field Application & Problem Solved

In small-to-medium rotating machinery—refinery lube oil pumps, power plant cooling fans, chemical plant compact turbines—the biggest probe challenge is finding a 5mm-diameter sensor with a 10ft cable that maintains signal integrity while fitting in tight spaces. Generic 5mm probes fail here in three critical ways: their cables use brittle PVC insulation (cracking in vibration-prone environments), lack proper shielding (picking up motor/VFD noise), or have mismatched impedance (causing sensitivity loss over 10ft runs). A Texas refinery lost $95k in a 2-hour outage when a generic probe’s PVC cable fractured in a lube pump housing, cutting off vibration data and leading to bearing seizure. A Pennsylvania food processing plant spent $18k annually replacing generic probes that introduced electrical noise into their fan monitoring system, triggering false trips.

This 330102 probe solves these issues with its factory-integrated 10ft PFA-shielded cable and 5mm compact design. You’ll find it in: auxiliary pump bearing housings, small turbine casings, cooling fan shafts, and any installation where space is limited but a 10ft cable is needed to reach the proximitor. It’s the standard for retrofitting legacy small machinery with 3300/3500 system compatibility, as its 72mm case length fits in shallow mounting bores that larger probes can’t access.

Its core value is compact form factor + mid-range cable reach + harsh-environment durability. Unlike generics, it’s impedance-matched to Bently proximitors, ensuring no loss of the 200 mV/mm sensitivity critical for accurate displacement measurements over 10ft. The PFA insulation resists oil, chemical washdowns, and temperature extremes, while the 100% braided shield blocks EMI/RFI. For a Louisiana water treatment plant, this probe enabled monitoring of their chemical dosing pumps—avoiding $22k in machinery modification costs and eliminating false trips caused by generic cable noise.

Installation & Maintenance Pitfalls (Expert Tips)

- Gap Setting: Mid-Range 1mm Is Non-Negotiable: Rookies set the probe gap too close (saturating the signal) or too far (losing linearity). An Ohio steel mill’s cooling fan monitor showed erratic readings until the gap was adjusted to 1mm (midpoint of the 2mm linear range). Use a precision feeler gauge—never guess based on visual alignment.

- Connector Torque: 0.8Nm (7.1 in-lbs) – Exact Value Matters: Over-torquing strips MIL connector threads; under-torquing causes intermittent signal loss. A Florida refinery’s probe failed after 4 months when the connector was torqued to 1.2Nm—invest in a torque wrench with a MIL adapter to avoid this.

- Cable Routing: 20cm Clearance from 240V+ Power Cables: The 10ft cable is prone to noise if run near low-voltage power lines. A Michigan paper mill’s pump vibration data had 60Hz hum until the cable was rerouted away from motor control wiring. Use shielded conduit for runs parallel to power cables.

- Shield Grounding: Single-Point at Proximitor End Only: Grounding the shield at both the probe and proximitor creates a ground loop, corrupting signals. A North Carolina refinery’s turbine data was unusable until we disconnected the shield from the pump housing and grounded it solely at the proximitor. Never splice or break the shield continuity.

- Inspect for Cable Abrasion in High-Vibration Areas: The 10ft cable’s braid wears thin when rubbing against machinery casings. A Texas chemical plant’s probe shorted after 12 months when the braid abraded on a pump mounting bolt—use rubber grommets or cable ties to secure high-wear sections.

Technical Deep Dive & Overview

The Bently 330102-00-72-10-02-05 is a purpose-built 5mm eddy current proximity probe designed for small-scale critical machinery. At its core, a precision-wound coil in the 5mm probe tip generates a high-frequency electromagnetic field. When a ferrous shaft (target) enters the field, eddy currents are induced in the shaft, altering the coil’s impedance. The integral 10ft cable transmits this impedance change to a 3300 XL Proximitor, which converts it into a linear voltage output (-24V to 0V) proportional to the probe-to-shaft gap—enabling accurate measurement of radial vibration, axial displacement, and eccentricity.

What sets this probe apart is its balance of compact size and signal integrity. The 5mm diameter fits in small bearing housings (common in auxiliary pumps/fans) where 8mm probes are too large, while the 10ft cable provides enough reach to route around machinery without splicing. The 50Ω impedance matching ensures no sensitivity loss over the 10ft run—unlike generic probes, which often see 15-20% sensitivity drop at this length. The PFA insulation outperforms PVC by resisting turbine lube oil, chemical cleaners, and temperature swings, while the 100% stainless steel braid blocks interference from VFDs and motor windings.

Unlike generic 5mm probes, it’s API 670 compliant, meeting strict reliability standards for machinery protection. Its 72mm case length allows deep mounting in recessed bores, and the MIL-C-5015 connector ensures a vibration-resistant connection that won’t loosen during operation. For maintenance teams, this probe isn’t just a sensor—it’s a reliable solution for extending 3300/3500 system monitoring to small, hard-to-reach assets. By providing accurate, noise-free data, it enables early detection of faults like bearing wear or shaft misalignment, preventing costly unplanned downtime in auxiliary machinery that’s often overlooked but critical to overall plant operations.