Description

Key Technical Specifications

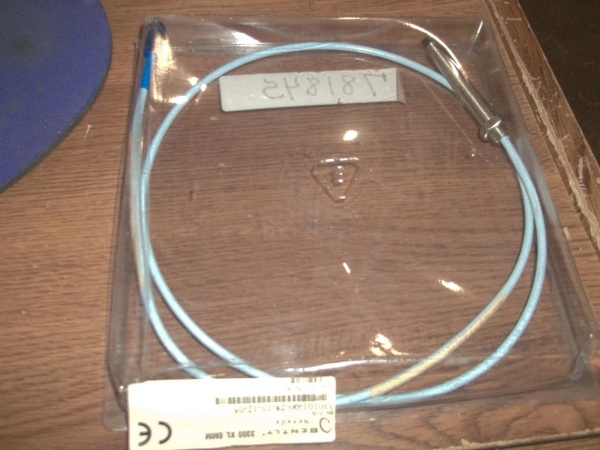

- Model Number: 330101-00-28-10-12-05

- Manufacturer: Bently Nevada (a Baker Hughes business)

- Probe Technology: Eddy current (non-contact, inductive)

- Probe Diameter: 5mm (0.197″) – compact for tight installation spaces

- Measurement Range: 0-2.8mm (0-0.110″) – optimized for small shaft movements

- Cable Length: 10ft (3.05m) – standard for most machinery installations

- Connector Type: 12-pin MIL-C-5015 male connector – secure industrial-grade connection

- Operating Temperature: -54°C to +121°C (-65°F to +250°F) – withstands extreme process environments

- Sensitivity: 800 mV/mm (20.32 mV/mil) typical (at 25°C) – high precision for small displacements

- Cable Construction: PFA insulation, stainless steel braided shield (EMI/RFI protection) – resists oil, chemicals, and electrical interference

- Isolation Rating: 500V AC (probe tip to cable shield) – prevents ground loop issues

- Certifications: CE, ATEX Zone 0 (Ex ia IIC T6), IECEx ia IIC T6 – suitable for hazardous areas

- Compatibility: Bently 3300 XL Proximitor Sensors, 3300 Series Monitor Systems, 1900 Series Vibration Monitors, 3500 Machinery Protection System

- Calibration: Factory-calibrated for ferrous targets (05 suffix indicates NIST-traceable calibration)

Field Application & Problem Solved

In rotating machinery with small-diameter shafts—refinery auxiliary turbines, power plant boiler feed pumps, chemical plant centrifugal pumps—the biggest challenge is precise, non-contact monitoring of tiny shaft movements. Generic probes are either too large for tight installation spaces or lack the sensitivity to detect small displacements (≤2mm) that precede bearing failure. A Pennsylvania power plant lost $170k in a 3.5-hour outage when a generic 8mm probe couldn’t fit in the pump housing, forcing a contact sensor that wore through the shaft seal. Legacy probes with low sensitivity also miss early warnings: a Texas refinery’s 2MW auxiliary turbine suffered catastrophic bearing failure because its old probe didn’t detect a 0.8mm shaft displacement.

This 5mm probe solves these issues. You’ll find it in: small-diameter turbines (≤100mm shaft), compact pumps, electric motor shafts, and any rotating asset where space is limited and precision is critical. It’s the go-to for auxiliary machinery in refineries, power plants, and chemical facilities—equipment that’s often overlooked but critical to overall process uptime.

Its core value is compact size + high sensitivity + harsh environment durability. Unlike larger 8mm probes, it fits in tight spaces without modifying machinery. The 800 mV/mm sensitivity detects even minute displacements, while the braided cable and wide temperature range withstand oil, chemicals, and extreme heat. For a Louisiana chemical plant, this probe enabled early detection of a 0.5mm shaft misalignment in a centrifugal pump, avoiding a 4-hour unplanned outage and $90k in repair costs.

Installation & Maintenance Pitfalls (Expert Tips)

- Probe-to-Target Gap: Set to Mid-Range (1.4mm): Rookies set the gap too close (≤0.5mm), risking contact during shaft movement, or too far (≥2.5mm), exceeding the measurement range. An Ohio steel mill’s pump probe failed after 2 weeks when the shaft contacted the tip—use a feeler gauge and proximitor to set the gap to 1.4mm (verify with 1.12V output at 800 mV/mm sensitivity).

- Cable Bending Radius: Minimum 15mm (0.6″): The 5mm probe’s cable is thinner than 8mm models—kinking it (bending radius <15mm) severs the internal conductors. A Florida refinery’s auxiliary turbine probe lost signal until the cable was rerouted with a 20mm bend radius. Use small cable ties to secure the cable—avoid sharp edges or tight bundles.

- Shield Grounding: Single-Point at Proximitor Only: Grounding the cable shield at both the probe and proximitor creates a ground loop, causing 60Hz noise in the signal. A Michigan paper mill’s vibration data showed false spikes until the shield was disconnected from the machinery housing and grounded solely at the proximitor.

- Target Surface Preparation: Machined to 1.6μm Finish: Rust, paint, or rough surfaces distort the eddy current signal. A North Carolina water treatment plant’s motor probe gave erratic readings until the shaft target area was cleaned and machined to a smooth finish. Avoid non-conductive coatings—even thin paint can reduce sensitivity by 30%.

- Calibration Verification: Annual Testing with Bently Kit: Rookies assume factory calibration lasts indefinitely, but vibration and temperature cycles drift sensitivity. A Texas refinery’s probe sensitivity dropped to 720 mV/mm after 18 months, leading to missed displacement alerts. Use a Bently 3300 Series calibration kit to verify sensitivity—replace the probe if drift exceeds ±5%.

Technical Deep Dive & Overview

The Bently 330101-00-28-10-12-05 is a compact eddy current proximity probe engineered for precise monitoring of small-diameter rotating shafts. At its core, a high-frequency oscillator (10MHz typical) generates an alternating magnetic field from the 5mm probe tip. When positioned near a ferrous shaft, the field induces eddy currents in the shaft’s surface—this interaction changes the probe’s electrical impedance proportionally to the probe-to-shaft gap.

The probe pairs with a Bently proximitor (e.g., 3300 XL), which converts the impedance change into a linear voltage output (0-2.24V = 0-2.8mm gap at 800 mV/mm sensitivity). The 12-pin MIL connector provides secure connectivity, while the stainless steel braided cable shields the signal from EMI/RFI—critical in environments with VFDs and electric motors. The 5mm diameter is 37.5% smaller than Bently’s 8mm probes (e.g., 330104), making it ideal for tight spaces like pump bearing housings or small turbine shafts.

What sets it apart is its balance of size and performance. The 2.8mm measurement range is optimized for small shaft movements, while the 800 mV/mm sensitivity is 4x higher than larger probes—enabling detection of minute displacements that precede failure. The rugged design (PFA insulation, wide temperature range, hazardous area certifications) ensures reliability in harsh industrial environments. For maintenance teams, this probe isn’t just a sensor—it’s a precision tool that protects critical auxiliary machinery, minimizing unplanned downtime and extending equipment life.