Description

Detailed parameter table

| Parameter name | Parameter value |

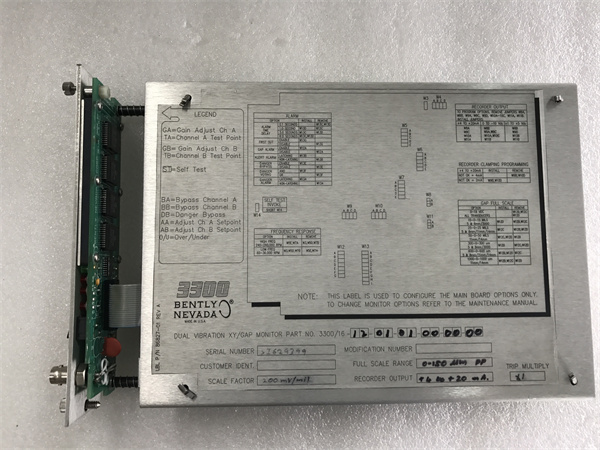

| Product model | 3300/16-11-01-03-00-00-01 |

| Manufacturer | Bently Nevada |

| Product category | Proximitor Sensor System Monitor Module |

| Channel configuration | 2 independent monitoring channels |

| Input type | Proximity probe signals (compatible with eddy current sensors) |

| Measurement type | Radial vibration, shaft position, differential expansion |

| Frequency range | 0 Hz to 10 kHz |

| Sensitivity | 8 mV/mil (315 mV/mm) ±5% (matches probe system specifications) |

| Alarm capability | Configurable dual alarm levels per channel (Alert, Danger) |

| Operating voltage | 24 VDC nominal (18-32 VDC range) |

| Power consumption | 3 W per channel, 6 W maximum |

| Operating temperature | -40°C to +70°C (-40°F to +158°F) |

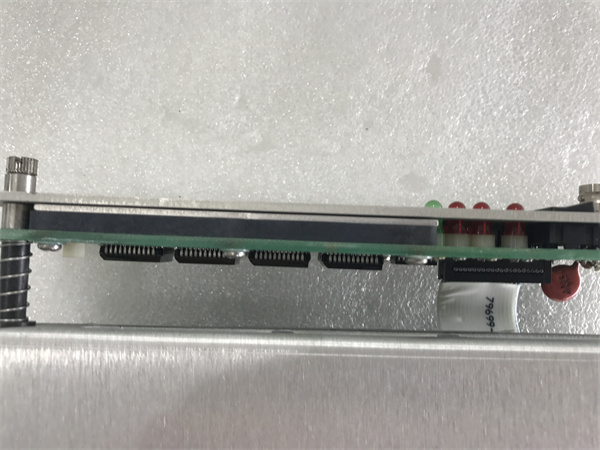

| Form factor | DIN rail mountable |

| Dimensions | 120 mm (H) × 100 mm (W) × 75 mm (D) (4.7″ × 3.9″ × 3.0″) |

| Compatibility | 330106-05-30-10-02-00 probe systems, 133323-01 cables, control systems |

| Certification | UL, CE compliant, RoHS compliant |

| Application | Standalone or distributed machinery vibration monitoring systems |

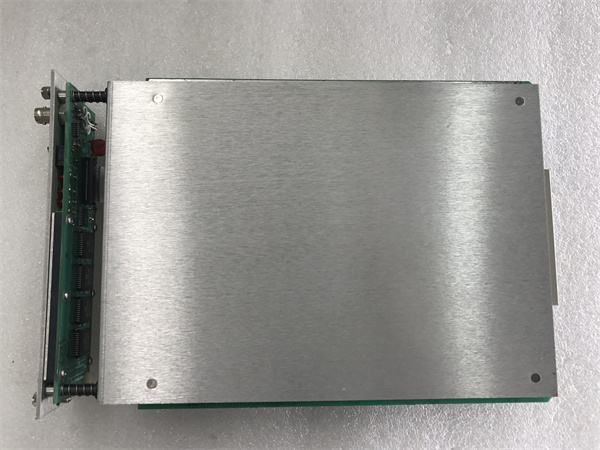

BENTLY 3300/16-11-01-03-00-00-01

Product introduction

The 3300/16-11-01-03-00-00-01 from Bently Nevada is a high-performance proximitor sensor system monitor module designed to process and analyze signals from eddy current proximity probe systems like the 330106-05-30-10-02-00. As part of the 3300 series, this 2-channel module serves as a critical interface between raw sensor data and actionable monitoring information, providing both protection and diagnostic capabilities for rotating machinery. Unlike rack-mounted 3500 series modules, this DIN rail-mountable unit offers flexible installation in distributed monitoring architectures while maintaining the precision expected from Bently Nevada systems.

Bently Nevada’s 3300/16-11-01-03-00-00-01 accepts low-level signals from proximity probes via cables like 133323-01, conditioning and processing them to derive meaningful measurements of shaft vibration, position, and differential expansion. The module converts these measurements into standard analog outputs and activates alarm relays when predefined thresholds are exceeded. Its compact design makes it ideal for installations where centralized rack systems are impractical, while its compatibility with 330106-05-30-10-02-00 probe systems ensures consistent measurement quality across both distributed and centralized monitoring architectures.

Core advantages and technical highlights

Seamless probe system integration: A key strength of 3300/16-11-01-03-00-00-01 is its optimized compatibility with 330106-05-30-10-02-00 and other 3300 series probe systems. The module’s 8 mV/mil sensitivity perfectly matches the probe system’s output characteristics, ensuring accurate signal conversion without additional calibration. This integration eliminates measurement errors that can occur with mismatched components, maintaining data integrity from sensor to output.

Dual-channel flexibility: The module’s two independent channels allow monitoring of multiple measurement points—such as radial vibration on opposite bearing housings or vibration and position on the same shaft—using a single device. Each channel features configurable alarm settings, enabling customized protection strategies for different machinery components while reducing installation complexity compared to single-channel alternatives.

Ruggedized design: With an operating temperature range of -40°C to +70°C (-40°F to +158°F), 3300/16-11-01-03-00-00-01 exceeds the environmental tolerance of many competing modules, making it suitable for harsh industrial environments where 330106-05-30-10-02-00 probes are typically installed. Its robust construction resists vibration, shock, and electrical interference, ensuring reliable operation in turbine enclosures, compressor stations, and manufacturing facilities.

Simplified system expansion: The DIN rail mounting design allows easy integration into existing control cabinets, supporting distributed monitoring architectures where sensors and processing modules are located near machinery rather than in centralized racks. This flexibility simplifies system expansion—additional modules can be added as new monitoring points are required, with each module connecting to 330106-05-30-10-02-00 probe systems via 133323-01 extension cables.

Typical application scenarios

Distributed turbine monitoring

In power generation facilities with multiple turbine sections, 3300/16-11-01-03-00-00-01 modules are installed near individual turbine bearings, each connected to 330106-05-30-10-02-00 probe systems monitoring radial vibration and shaft position. This distributed approach reduces the length of critical sensor cables (supplemented only when necessary with 133323-01 extensions) and brings processing closer to measurement points, minimizing signal degradation. The modules transmit conditioned data to central control systems, providing both local alarm indication and remote monitoring capability.

Compressor skid integration

Oil and gas compressor skids utilize 3300/16-11-01-03-00-00-01 modules mounted directly on the skid, connected to proximity probes monitoring compressor shaft behavior. The module’s compact size allows installation in space-constrained compressor enclosures, while its wide temperature tolerance ensures performance in the heat generated by compression processes. Alarm outputs trigger local shutdown circuits and send signals to plant SCADA systems, providing both immediate protection and centralized monitoring.

Retrofit machinery protection

In manufacturing plants upgrading legacy machinery with modern monitoring, 3300/16-11-01-03-00-00-01 modules provide a cost-effective solution that integrates with new 330106-05-30-10-02-00 probe systems. The DIN rail mounting allows easy installation in existing control panels without major modifications, while the module’s analog outputs connect to legacy PLCs or new DCS systems. This approach enables incremental upgrades to machinery protection without requiring complete system overhauls.

BENTLY 3300/16-11-01-03-00-00-01

Related model recommendations

330106-05-30-10-02-00: Proximity probe system providing raw signals to the monitor module.

133323-01: Extension cable for connecting probe systems to the monitoring module.

3500/40M 140734-01: Rack-mounted monitoring module for centralized systems (complementary to this distributed module).

3500/05-01-02-00-00-00: Communication module for integrating distributed data into enterprise systems.

3500/25 184684-01: Relay module for expanded protection actions based on alarm signals.

3300/07: Signal conditioner for additional channel expansion in distributed systems.

133300-01: Interface cable for connecting the module to control system inputs.

3500/60 163179-01: Display module for visualizing data from distributed monitoring points.

Installation, commissioning and maintenance guidelines

Installation

Mount 3300/16-11-01-03-00-00-01 on standard DIN rails in control cabinets or near monitored machinery, ensuring ambient temperature remains within -40°C to +70°C range. Connect 330106-05-30-10-02-00 probe systems to the module’s input terminals using shielded cables, extending with 133323-01 cables when necessary. Route cables away from high-voltage lines and noise sources, grounding the shield at the module end. Connect power (24 VDC) and wire alarm outputs to appropriate control or annunciator systems. Ensure proper spacing (minimum 50 mm) between modules for heat dissipation.

Commissioning

After installation, configure 3300/16-11-01-03-00-00-01 using compatible configuration software or front-panel controls to set measurement types, alarm thresholds, and time delays for each channel. Verify the 8 mV/mil sensitivity matches the connected 330106-05-30-10-02-00 probe system. Perform a calibration check using known displacement inputs to confirm measurement accuracy. Test alarm functionality by simulating excessive vibration or position values, ensuring proper relay activation and reset behavior. Document configuration settings and baseline measurements for future reference.

Maintenance

Include 3300/16-11-01-03-00-00-01 in semi-annual system inspections. Verify power supply stability and check status indicators for normal operation. Inspect connections to 330106-05-30-10-02-00 probes and 133323-01 cables for tightness and corrosion. Perform annual accuracy verification using calibrated test equipment, comparing measurements to baseline values. Clean ventilation openings if dust accumulation is observed. Update firmware during scheduled maintenance if improvements or bug fixes are available. Replace modules if measurements drift beyond specifications or if alarm functionality fails.

Service and guarantee commitment

Bently Nevada provides the 3300/16-11-01-03-00-00-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including measurement accuracy, alarm functionality, and component reliability when used with compatible probe systems like 330106-05-30-10-02-00 and cables such as 133323-01. Our technical support team offers expert guidance on module configuration, system integration, and troubleshooting in distributed monitoring architectures.

We offer specialized training on proximity system integration, module programming, and maintenance procedures specific to 3300/16-11-01-03-00-00-01. Beyond the warranty period, our service agreements include calibration verification, technical support, and expedited replacement services to maintain monitoring system integrity. Bently Nevada’s commitment to quality ensures reliable performance throughout the module’s operational lifecycle, backed by our global network of service professionals.