Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 1900/27 |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Controller |

| Series affiliation | 1900 Machinery Protection System |

| Input channels | 8 configurable sensor input channels |

| Output relays | 4 Form C alarm relays, 2 Form C shutdown relays |

| Communication interface | RS-485 Modbus RTU, Ethernet IP |

| Operating voltage | 18-30 VDC |

| Power consumption | Max 15W |

| Operating temperature | -20°C to +65°C (-4°F to +149°F) |

| Enclosure rating | NEMA 4X (IP66) when panel-mounted |

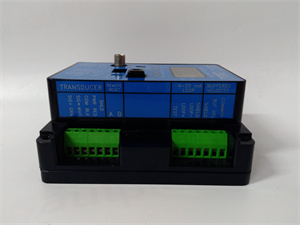

| Display type | 2-line LCD display with LED status indicators |

| Certification | Compliant with CE, UL, and API 670 standards |

BENTLY 1900/27

Product introduction

The 1900/27 from Bently Nevada is a compact yet powerful machinery protection system controller designed to monitor critical rotating equipment in industrial environments. As the central processing unit of the 1900 series, this controller aggregates data from multiple sensors, processes measurement signals, and triggers appropriate protection actions when abnormal conditions are detected. Bently Nevada’s 1900/27 delivers essential machinery health monitoring capabilities in a space-efficient design, making it ideal for applications where rack space is limited but protection reliability cannot be compromised.

Bently Nevada’s 1900/27 serves as the intelligence hub for machinery protection, continuously analyzing vibration, temperature, position, and other key parameters from connected sensors. Its configurable logic allows customization of alarm thresholds, time delays, and protection sequences to match specific machinery requirements. The 1900/27 ensures that potential equipment faults are detected early, providing operators with actionable alerts while initiating protective measures to prevent catastrophic failures—making it a vital component in industrial asset protection strategies.

Core advantages and technical highlights

Comprehensive monitoring capability: The 1900/27 features 8 configurable input channels that accept signals from various sensor types, including proximity probes, accelerometers, and RTDs. This versatility allows it to monitor multiple machinery parameters simultaneously—vibration, bearing temperature, shaft position, and casing expansion—providing a holistic view of equipment health similar to how the 24765-02-00 focuses on thermal expansion but with broader monitoring scope.

Industrial-grade reliability: Built to withstand harsh operating environments, the 1900/27 operates reliably across a -20°C to +65°C temperature range and carries a NEMA 4X (IP66) rating when panel-mounted. This rugged design ensures consistent performance in dusty, wet, or corrosive environments, from offshore platforms to chemical processing plants, where equipment protection is critical.

Flexible communication options: Equipped with both RS-485 Modbus RTU and Ethernet IP interfaces, the 1900/27 seamlessly integrates with SCADA systems, DCS platforms, and asset management software. This connectivity enables remote monitoring of machinery health data, facilitating centralized asset management while allowing operators to access critical information from control rooms or mobile devices.

Configurable protection logic: The 1900/27 offers highly customizable alarm and shutdown logic through intuitive configuration software. Users can define multi-stage alarm thresholds, time delays, and interlock conditions to match specific machinery protection requirements. This flexibility ensures the controller can be tailored to protect various equipment types, from pumps and motors to turbines and compressors.

Typical application scenarios

In oil and gas production facilities, the 1900/27 protects critical rotating equipment such as centrifugal pumps, reciprocating compressors, and gas turbines. By monitoring vibration, bearing temperature, and shaft position—complemented by thermal expansion data from devices like the 24765-02-00—it provides early warning of developing faults such as impeller wear, bearing degradation, or misalignment. The controller’s rapid response capability ensures timely shutdowns during severe conditions, preventing costly equipment damage and unplanned production downtime.

Power generation plants utilize the 1900/27 to protect boiler feed pumps, cooling tower fans, and auxiliary turbines. Its ability to monitor multiple parameters simultaneously allows operators to detect issues like rotor imbalance, lubrication failure, or thermal stress—critical factors in maintaining reliable power generation. The controller’s communication capabilities integrate with plant DCS systems, providing centralized monitoring of all auxiliary equipment health.

Manufacturing facilities deploy the 1900/27 on production line machinery, including conveyors, mixers, and industrial fans. By continuously monitoring vibration signatures and temperature profiles, it identifies mechanical issues before they cause production interruptions. The controller’s compact design makes it suitable for installation in space-constrained factory environments while still delivering robust protection capabilities.

BENTLY 1900/27

Related model recommendations

1900/16 (Bently Nevada): 16-channel expansion module that extends the monitoring capability of the 1900/27.

24765-02-00 (Bently Nevada): Case expansion transducer whose data can be integrated into the 1900/27 for comprehensive thermal monitoring.

330180-90-01 (Bently Nevada): Proximity sensor commonly paired with the 1900/27 for shaft position monitoring.

133819-01 (Bently Nevada): Signal conditioning amplifier that enhances sensor data quality for the 1900/27.

1900/55 (Bently Nevada): HMI interface panel that provides local control and visualization for the 1900/27.

60M100-00 (Bently Nevada): Advanced display unit that can visualize data processed by the 1900/27.

125840-01 (Bently Nevada): Power supply module compatible with the 1900/27 in redundant configurations.

3500/62 (Bently Nevada): Relay output module that can be integrated with the 1900/27 for expanded control capabilities.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the 1900/27, ensure the mounting location provides stable ambient conditions within the -20°C to +65°C range and proper ventilation. Verify the power supply delivers 18-30 VDC with appropriate surge protection. Required tools include torque screwdrivers, wire strippers, and a laptop with configuration software. Inspect the 1900/27 for shipping damage, particularly checking connector pins and display components. Plan sensor wiring routes to minimize electromagnetic interference, using shielded cables terminated at both ends.

Maintenance suggestions: Conduct quarterly visual inspections of the 1900/27 to check for loose connections, corrosion, or debris accumulation. Verify LED status indicators show normal operation and review alarm logs for any intermittent issues. Calibrate input channels annually using certified standards to maintain measurement accuracy, similar to calibration practices for the 24765-02-00. Backup configuration files regularly and store them securely for quick recovery. When troubleshooting, check power supply integrity first, then verify sensor connections before investigating controller diagnostics. Update firmware during scheduled maintenance to benefit from performance improvements.

Service and guarantee commitment

Bently Nevada backs the 1900/27 with a 24-month warranty covering manufacturing defects and component failures from the date of shipment. Our technical support team provides expert assistance for system configuration, integration, and troubleshooting, ensuring optimal performance of the 1900/27 in your specific application environment.

We offer specialized training programs focused on programming, operation, and maintenance of the 1900/27, equipping your team with the skills to maximize protection system effectiveness. Beyond the warranty period, our service agreements include preventive maintenance checks, calibration services, and expedited repair options to minimize downtime. Bently Nevada’s commitment to quality ensures the 1900/27 delivers reliable machinery protection throughout its operational lifecycle, supported by our global network of service professionals.