Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 184684-01 (specific variant of 3500/25) |

| Manufacturer | Bently Nevada |

| Product category | Machinery Protection System Relay Output Module |

| Relay configuration | 8 Form C (changeover) relays |

| Contact rating | 5 A @ 250 VAC, 5 A @ 30 VDC |

| Response time | <10 ms |

| Operating voltage | 5 VDC, ±15 VDC (from 3500/15 106M1079-01 power supply) |

| Power consumption | 7 W typical, 8 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

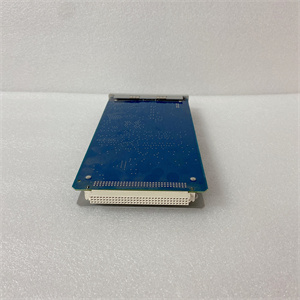

| Form factor | 3500 system rack mount (2 slot width) |

| Dimensions | 266 mm (H) × 72 mm (W) × 229 mm (D) (10.5″ × 2.8″ × 9.0″) |

| Compatibility | 125744-02 racks, 3500/44M 176449-03 monitors, 133292-01 cables |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

BENTLY 184684-01

Product introduction

The 184684-01 from Bently Nevada is a high-performance relay output module and the standard variant of the 3500/25 series, serving as the critical interface between monitoring systems and protective action devices in 3500 Machinery Protection Systems. This 2-slot module features 8 Form C (changeover) relays that convert digital alarm signals from monitoring components into tangible protective actions, forming the enforcement layer of machinery protection architectures. As the most widely deployed variant in the 3500/25 series, 184684-01 is engineered to deliver reliable, fast-acting protection for critical rotating machinery across diverse industrial applications.

Bently Nevada’s 184684-01 receives alarm commands from monitoring modules like 3500/44M 176449-03 through the 3500 rack backplane, then activates the appropriate relays to trigger predefined responses such as equipment shutdowns, alarm annunciations, or control system interventions. Installed in 125744-02 racks and powered by 3500/15 106M1079-01 supplies, this module ensures that detected machinery abnormalities result in immediate protective actions, preventing minor issues from escalating into catastrophic failures. Its balanced design makes it suitable for most general industrial protection applications requiring multiple coordinated protective responses.

Core advantages and technical highlights

Optimized relay configuration: 184684-01 features 8 independent Form C relays in a compact 2-slot design, providing an ideal balance of density and functionality for general industrial applications. Each relay includes normally open (NO), normally closed (NC), and common contacts, enabling flexible wiring to various control devices without requiring external relay panels. This configuration supports multiple simultaneous protective actions, from simple alarms to complex shutdown sequences.

Ultra-fast response time: With a relay activation time of less than 10 ms, 184684-01 ensures that protective actions are initiated almost instantaneously when critical alarms are detected. This rapid response is essential for mitigating damage during sudden machinery anomalies such as severe vibration spikes, overspeed conditions, or excessive axial movement in high-speed rotating equipment.

Industrial-grade contact reliability: The module’s relay contacts are rated for 5 A at 250 VAC or 30 VDC, making them compatible with a wide range of industrial control devices. This rating allows direct control of annunciators, solenoid valves, motor starters, and shutdown circuits, eliminating the need for intermediate relays in most applications and simplifying system architecture.

Customizable operation logic: Each relay in 184684-01 can be independently configured for latching or non-latching operation, with adjustable time delays for both activation and deactivation. This customization enables precise tailoring of protection strategies to specific machinery requirements, preventing nuisance trips from transient conditions while ensuring reliable response to genuine faults. Configuration is simplified through connection to 3500/05-01-03-00-00-00 communication modules, often using 133292-01 cables for setup.

Typical application scenarios

Turbine generator protection

In power generation facilities, 184684-01 modules form the protective action layer for turbine-generator sets. They receive alarm signals from 3500/44M 176449-03 monitors tracking vibration, temperature, and axial position, then activate specific relays to trigger tiered responses: first activating control room alarms, then initiating lube oil system adjustments, and finally triggering emergency shutdown if conditions worsen. This tiered approach maximizes equipment availability while ensuring protection during critical conditions.

Centrifugal compressor safety systems

Oil and gas processing facilities utilize 184684-01 to protect centrifugal compressors by translating vibration, pressure, and temperature alarms into protective actions. Relays are configured to activate local annunciators, isolate process valves, and initiate compressor shutdown sequences when unsafe conditions are detected. The module’s fast response time is critical for preventing damage during surge conditions or bearing failures in high-pressure compressor applications.

Manufacturing line critical motor protection

In manufacturing environments, 184684-01 modules protect production-critical motors by triggering conveyor stops, process interruptions, or maintenance alerts when abnormal vibration or temperature conditions are detected. The relays interface with plant PLCs to integrate machinery protection with production control systems, ensuring coordinated responses that minimize downtime while preventing equipment damage. This integration helps maintain production schedules while protecting valuable motor assets.

BENTLY 184684-01

Related model recommendations

3500/25: Base relay module series that includes the 184684-01 variant.

3500/44M 176449-03: Monitoring module that sends alarm signals to 184684-01.

3500/15 106M1079-01: Power supply module providing regulated power to the relay module.

125744-02: Rack assembly housing the 184684-01 module and associated components.

3500/05-01-03-00-00-00: Communication module enabling configuration and monitoring.

133292-01: Communication cable for configuration connections to the relay module.

136180-01: Configuration module for programming relay logic and parameters.

3500/60 163179-01: Display module showing relay activation status and alarm conditions.

Installation, commissioning and maintenance instructions

Installation

Install 184684-01 in a 125744-02 rack with a properly configured 3500/15 106M1079-01 power supply. Ensure two adjacent slots are available, typically positioned near monitoring modules for efficient backplane communication. Connect control wiring to relay terminals using 14-22 AWG wire, torquing terminal screws to 0.5-0.6 N·m. Use shielded cables for sensitive circuits and route wiring separately from power conductors to minimize electromagnetic interference. Establish communication links to configuration tools via 133292-01 cables connected to 3500/05-01-03-00-00-00 modules.

Commissioning

After installation, configure 184684-01 using 136180-01 tools or via communication with 3500/05-01-03-00-00-00 modules. Program each relay’s associated alarm sources, latching behavior, and time delays to match machinery protection requirements. Test relay operation by simulating alarm conditions from connected monitoring modules, verifying both contact activation (using a multimeter) and proper status indication on 3500/60 163179-01 displays. Confirm that protective actions (such as shutdown circuits) function correctly when relays activate, and document all relay assignments and test results.

Maintenance

Include 184684-01 in quarterly safety system inspections. Verify status indicators function correctly and inspect relay terminals for corrosion or loose connections. Perform annual contact resistance testing using a micro-ohmmeter to ensure contacts remain below 100 mΩ. Test relay operation by manually activating each relay through configuration software and verifying proper response. Clean terminal blocks annually with approved electronic contact cleaner and tighten any loose connections. Replace the module if relays fail to operate within specified response times or contact resistance exceeds limits.

Service and guarantee commitment

Bently Nevada provides the 184684-01 with a 36-month warranty covering manufacturing defects and performance issues under normal operating conditions, including relay reliability, contact integrity, and response time when powered by compatible supplies like 3500/15 106M1079-01. Our technical support team offers expert guidance on relay configuration, safety system integration, and troubleshooting interactions with monitoring modules like 3500/44M 176449-03.

We offer specialized training on relay logic programming, safety instrumented system design, and maintenance procedures specific to 184684-01. Beyond the warranty period, our service agreements include functional testing, contact cleaning, and expedited replacement services to ensure continuous protection system operation. Bently Nevada’s commitment to quality ensures reliable protective action capability throughout the module’s operational lifecycle, backed by our global network of service professionals.