Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 177230-01-01-05 |

| Manufacturer | Bently Nevada |

| Product category | Proximity Probe Extension Cable Assembly |

| Cable type | Shielded twisted-pair with integral Microdot connectors |

| Length | 5 meters (16.4 feet) |

| Connector type | Microdot male to Microdot female |

| Conductor gauge | 24 AWG stranded copper |

| Shielding | Dual-layer (foil + braid) with 100% coverage |

| Impedance | 50 ohms ±5% (nominal) |

| Operating temperature | -54°C to +121°C (-65°F to +250°F) |

| Voltage rating | 300 VAC RMS |

| Compatibility | 3500/15 127610-01 power modules, 330106-05-30-10-02-00 probes, 3500 systems |

| Certification | UL, CE, RoHS compliant, IEC 60068-2 approved |

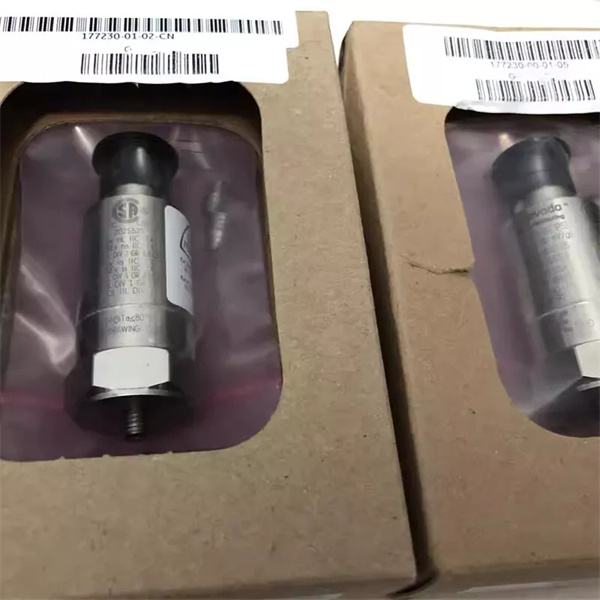

BENTLY 177230-01-01-05

Product introduction

The 177230-01-01-05 from Bently Nevada is a high-performance proximity probe extension cable assembly engineered to maintain signal integrity between proximity probes and monitoring modules in machinery protection systems. This 5-meter shielded cable serves as a critical link in the measurement chain, ensuring that low-level vibration and position signals from sensors like the 330106-05-30-10-02-00 reach monitoring equipment without degradation.

Unlike generic industrial cables, 177230-01-01-05 is specifically designed for the unique requirements of eddy current proximity probe systems, featuring precise impedance matching and specialized shielding to preserve signal quality over extended distances. Its compatibility with 3500 series systems means it works seamlessly with power modules like the 3500/15 127610-01 and associated monitoring components, forming an integrated measurement pathway from sensor to analysis.

In machinery protection ecosystems, 177230-01-01-05 plays an essential role in extending monitoring capabilities to hard-to-reach machinery locations. By maintaining the 8 mV/mil sensitivity specification of connected probes, it ensures accurate measurement of shaft vibration and position—data that directly impacts the reliability of protective alarms and diagnostic analysis in power generation, oil and gas, and manufacturing applications.

Core advantages and technical highlights

Signal integrity preservation: 177230-01-01-05 features precision 50-ohm impedance matching that minimizes signal reflection and loss, critical for maintaining the accuracy of proximity probe measurements over its 5-meter length. This controlled impedance ensures that the subtle voltage variations (8 mV/mil) from probes like 330106-05-30-10-02-00 remain intact, preserving measurement accuracy that could otherwise be compromised by generic cables with inconsistent impedance characteristics.

Enhanced electromagnetic shielding: The cable incorporates dual-layer shielding (aluminum foil with drain wire plus tinned copper braid) providing 100% coverage, effectively blocking electromagnetic interference (EMI) and radio frequency interference (RFI) from industrial environments. This shielding is electrically continuous through the connectors, creating a complete EMI barrier that protects sensitive probe signals from noise generated by motors, variable frequency drives, and other industrial equipment powered by modules like 3500/15 127610-01.

Industrial-grade durability: Constructed to withstand harsh operating conditions, 177230-01-01-05 operates reliably across a -54°C to +121°C temperature range, making it suitable for installation in turbine enclosures, compressor housings, and other extreme environments. Its oil-resistant, flame-retardant jacket resists chemical exposure, abrasion, and mechanical stress, ensuring long-term performance in demanding industrial settings where cable failure could compromise machinery protection.

Precision connector integration: Equipped with factory-installed Microdot connectors, 177230-01-01-05 eliminates the reliability issues associated with field-terminated connections. These precision connectors feature gold-plated contacts that ensure low-resistance signal paths and corrosion resistance, maintaining stable performance even after thousands of thermal cycles common in industrial machinery applications.

Typical application scenarios

In combined cycle power plants, 177230-01-01-05 cables extend proximity probe connections from gas turbine bearings to monitoring racks located in control rooms. The 5-meter length allows flexible routing around turbine casings and through cable trays, while its shielding protects signals from EMI generated by generator systems powered by 3500/15 127610-01 modules. This ensures accurate vibration measurement for early detection of bearing degradation in critical turbine components.

Oil refineries utilize 177230-01-01-05 in centrifugal compressor monitoring systems, connecting probes mounted on compressor bearing housings to remote monitoring modules. The cable’s chemical-resistant jacket withstands exposure to hydrocarbon vapors, while its shielding protects against electrical noise from nearby pump motors. In these applications, the cable maintains signal integrity that enables detection of subtle vibration patterns indicating impeller imbalance or seal wear.

Pulp and paper mills employ 177230-01-01-05 to connect proximity probes on large process pumps to monitoring systems, where the cable’s rugged construction resists moisture, pulp fibers, and cleaning chemicals. The 5-meter length accommodates the distance between pump skids and control panels, while its EMI shielding prevents interference from variable frequency drives controlling pump motors. This reliable signal transmission ensures timely detection of bearing issues in pumps critical for continuous production.

Related model recommendations

330106-05-30-10-02-00: Proximity probe system directly compatible with 177230-01-01-05 extension cables.

3500/15 127610-01: Power supply module supporting monitoring systems connected via this cable.

3500/40M 140734-01: Vibration monitor receiving signals through 177230-01-01-05 cables.

133819-02: Interface cable that complements this extension cable in complete systems.

3500/72M: Temperature monitor in systems using 177230-01-01-05 for vibration probe connections.

3500/62-04-02: Display module visualizing data from sensors connected via this cable.

133323-01: Shorter extension cable option compatible with 177230-01-01-05 for system flexibility.

84152-01: Calibration tool used to verify systems incorporating this extension cable.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing 177230-01-01-05, verify the cable length matches the installation distance to avoid unnecessary coiling, which can create EMI antenna effects. Inspect connectors for damage or contamination, cleaning with approved electronic contact cleaner if necessary. Plan cable routes away from high-voltage power cables, motor leads, and variable frequency drive wiring to minimize EMI exposure. Use non-metallic cable ties to secure the cable, avoiding over-tightening that could damage the jacket or affect impedance characteristics. Ensure proper grounding of the cable shield at the monitoring end only to prevent ground loops.

Maintenance suggestions: Include 177230-01-01-05 in semi-annual inspection programs, visually checking for jacket damage, connector corrosion, or shielding compromise. During system calibration with tools like 84152-01, verify signal continuity and integrity through the cable. Secure any loose sections to prevent vibration-induced wear, especially near connectors and cable entry points. Avoid bending the cable beyond its minimum bend radius (15 mm for static installation, 30 mm for dynamic). Replace cables immediately if insulation damage, connector wear, or signal degradation is detected, as compromised cables can lead to incorrect measurements and unreliable machinery protection.

Service and guarantee commitment

Bently Nevada provides the 177230-01-01-05 with a 24-month warranty covering manufacturing defects and performance issues under normal operating conditions, including shielding integrity, connector reliability, and signal transmission capability when used with compatible probes like 330106-05-30-10-02-00 and systems powered by 3500/15 127610-01. Our technical support team offers expert guidance on cable routing, installation best practices, and troubleshooting signal integrity issues.

We provide recommendations for system integration to maximize the performance and longevity of 177230-01-01-05 in industrial environments. Beyond the warranty period, our service agreements include cable testing services and expedited replacement to maintain system reliability. Bently Nevada’s commitment to quality ensures that 177230-01-01-05 provides consistent, interference-free signal transmission throughout its operational lifecycle, backed by our global network of service professionals dedicated to protecting your critical machinery assets.