Description

Detailed parameter table

| Parameter name | Parameter value |

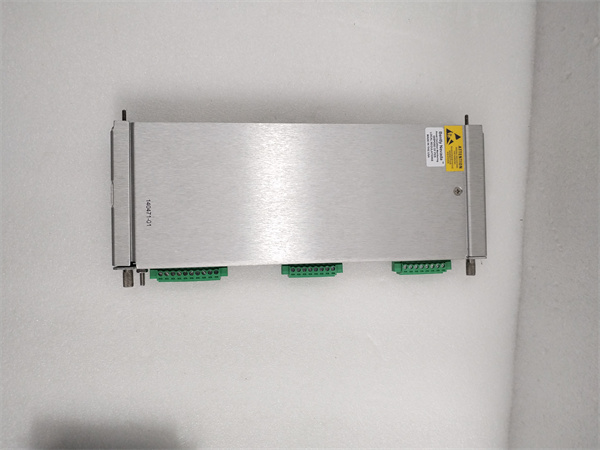

| Product model | 140471-01 |

| Manufacturer | Bently Nevada |

| Product category | Signal Conditioning Module |

| Series affiliation | 3500 Machinery Protection System |

| Input channels | 4-channel analog input |

| Input type | Vibration, acceleration, and pressure signals |

| Input range | ±5 VDC, ±10 VDC, 4-20 mA (configurable per channel) |

| Frequency response | 0.1 Hz to 10 kHz (-3 dB) |

| Output signal | conditioned analog (0-10 VDC) and digital (EtherCAT) |

| Operating voltage | 24 VDC (powered by 3500/05-01-02-00-00-01 power supply) |

| Power consumption | 4 W typical, 6 W maximum |

| Operating temperature | 0°C to +60°C (32°F to +140°F) |

| Storage temperature | -40°C to +85°C (-40°F to +185°F) |

| Form factor | DIN rail mount / 3500 system rack mount (1 slot width) |

| Dimensions | 120 mm (H) × 80 mm (W) × 100 mm (D) (4.7″ × 3.1″ × 3.9″) |

| Protection features | Channel isolation, overvoltage protection, surge protection |

| Compatibility | 128275-01-E sensor systems, 3500/34 communication modules, 136188-01 signal input modules |

| Certification | UL, CE, RoHS compliant, IEC 61010-1 approved |

| Calibration features | Field-calibratable, NIST-traceable, auto-calibration capability |

BENTLY 140471-01

Product introduction

The 140471-01 from Bently Nevada is a precision signal conditioning module designed to enhance measurement accuracy in 3500 Machinery Protection Systems. This compact module processes raw analog signals from various industrial sensors, providing conditioned outputs that improve data quality for both local protection and enterprise monitoring. Bently Nevada’s 140471-01 acts as a critical intermediate component in the measurement chain, refining signals from sensor systems like the 128275-01-E before they reach signal input modules such as the 136188-01 and ultimately flow through the 3500/34 communication gateway to monitoring and analytics platforms.

Bently Nevada’s 140471-01 addresses the challenge of noisy industrial environments where raw sensor signals may contain interference or require amplification. Its advanced conditioning circuitry filters electrical noise, compensates for environmental factors, and standardizes signal levels—ensuring that the vibration, acceleration, and pressure data used for machinery protection and diagnostics is accurate and reliable. This module plays a vital role in preserving measurement integrity, directly impacting the quality of data visualized on operator displays and analyzed in enterprise systems.

Core advantages and technical highlights

Advanced signal conditioning: The 140471-01 incorporates multi-stage filtering and amplification that removes electrical noise and artifacts from raw sensor signals. Its configurable low-pass, high-pass, and notch filters can be tailored to specific measurement requirements, ensuring that only relevant frequency components are passed to downstream modules like the 136188-01.

Channel independence: Each of the four channels operates independently with dedicated conditioning circuitry, eliminating cross-talk and ensuring that signals from one channel don’t interfere with others. This isolation is particularly valuable when monitoring different types of measurements (e.g., vibration and pressure) from adjacent machinery components.

Flexible input adaptation: The module accepts a wide range of input types and ranges (±5 VDC, ±10 VDC, 4-20 mA), enabling direct connection to various sensor types without requiring additional interface hardware. This flexibility simplifies system integration when working with mixed sensor technologies in complex machinery monitoring applications.

Dual output capability: Providing both conditioned analog outputs (0-10 VDC) for local processing and digital outputs via EtherCAT, the 140471-01 supports parallel data paths for protection and analytics. This dual capability ensures that high-speed protection loops receive filtered signals locally while raw and processed data can be simultaneously transmitted to the 3500/34 gateway for enterprise analysis.

Typical application scenarios

In power generation turbine systems, the 140471-01 conditions vibration signals from 128275-01-E proximity sensors and accelerometers mounted on turbine casings. Its notch filters remove 50/60 Hz line noise and harmonic interference from generator systems, while its amplification ensures low-level vibration signals are properly resolved. Conditioned signals are sent to 136188-01 modules for protection logic and simultaneously to the 3500/34 gateway for transmission to plant DCS and analytics platforms.

Oil and gas compressor stations utilize the 140471-01 to process pressure and vibration data from reciprocating compressors, where harsh operating conditions can introduce significant noise into sensor signals. The module’s rugged design withstands the environmental challenges of compression facilities, while its advanced filtering removes pulsation-related noise from pressure signals. Conditioned data helps operators distinguish between normal operational vibrations and potential mechanical issues like valve wear or cylinder imbalance.

Manufacturing facilities deploy the 140471-01 in production line monitoring systems, where it conditions acceleration signals from motor and gearbox sensors. Its channel isolation prevents electrical noise from variable frequency drives from corrupting vibration measurements, ensuring accurate detection of bearing faults and misalignment. The module’s digital outputs feed processed data to both local protection relays and the 3500/34 communication gateway, supporting both immediate fault response and long-term predictive maintenance programs.

BENTLY 140471-01

Related model recommendations

128275-01-E (Bently Nevada): Proximity sensor system whose signals are conditioned by 140471-01.

3500/34 (Bently Nevada): Communication gateway transmitting data from 140471-01.

136188-01 (Bently Nevada): Signal input module receiving conditioned outputs from 140471-01.

3500/05-01-02-00-00-01 (Bently Nevada): Power supply for the 140471-01 module.

3500/20 (Bently Nevada): System rack housing the 140471-01 when used in rack-mount configuration.

163179-01 (Bently Nevada): Extension cable connecting sensors to 140471-01.

330130-080-00-00 (Bently Nevada): Calibration fixture for 140471-01 verification.

3500/60 (Bently Nevada): Display module visualizing data processed by 140471-01.

Installation, configuration and maintenance instructions

Installation preparation: Before installing the 140471-01, verify compatibility with connected sensors (such as 128275-01-E) and downstream modules like the 136188-01. Choose a mounting location within the 0°C to +60°C operating range with adequate ventilation. Required tools include a screwdriver set, wire strippers, torque wrench, and laptop with configuration software. Inspect the module for shipping damage, checking for loose components, damaged connectors, or visible signs of stress.

Mounting and wiring: Install the 140471-01 using either DIN rail clips or rack mount adapters for 3500/20 racks, ensuring secure attachment to prevent vibration-induced issues. Connect 24 VDC power from the 3500/05-01-02-00-00-01 supply, verifying correct polarity. Wire sensor inputs using shielded twisted-pair cable, connecting to the appropriate terminal blocks based on input type. Connect conditioned outputs to downstream modules, ensuring proper signal routing to both protection systems and the 3500/34 communication gateway.

Configuration procedures: Power on the system and establish communication with the 140471-01 via USB or network connection using configuration software. Configure each channel for the specific sensor type, setting input ranges, filter parameters, and gain levels to optimize signal quality. Set up output scaling to match the requirements of receiving modules. Configure digital communication parameters to ensure compatibility with the 3500/34 gateway for data transmission. Save and backup configuration settings after verification.

Maintenance suggestions: Include the 140471-01 in quarterly preventive maintenance routines, checking for loose connections, dust accumulation, and proper indicator status. Verify calibration annually using the 330130-080-00-00 fixture, comparing actual output against known input signals. Clean ventilation openings as needed to maintain proper cooling. During scheduled shutdowns, inspect wiring for signs of corrosion or damage and retorque connections if necessary. If signal quality issues occur, check filter settings and calibration before suspecting hardware failure, and verify proper power supply voltage.

Service and guarantee commitment

Bently Nevada provides the 140471-01 with a 30-month warranty covering manufacturing defects and component failures under normal operating conditions. Our technical support team offers expert guidance on proper installation, configuration, and integration with sensor systems like the 128275-01-E, signal input modules such as the 136188-01, and communication gateways including the 3500/34.

We offer specialized training on signal conditioning principles, filter configuration, and calibration procedures specific to the 140471-01. Beyond the warranty period, our service agreements include calibration verification, performance testing, and expedited replacement services to minimize downtime. Bently Nevada’s commitment to quality ensures the 140471-01 delivers reliable signal conditioning throughout its operational lifecycle, backed by our global network of service professionals and application engineers.