Description

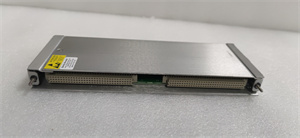

BENTLY 126599-01 Aero GT I/O Module with Internal Terminations

1. Product Description

The BENTLY 126599-01 is a high-performance I/O module designed for BENTLY Nevada’s 3500/44 M aeroderivative gas turbine vibration monitoring system. Specifically engineered for aviation and industrial gas turbine applications, this four-channel module supports precise measurement and control of critical parameters such as vibration, displacement, and temperature. With internal terminations and rugged construction, the BENTLY 126599-01 ensures reliable operation in harsh environments, including extreme temperatures and high-vibration settings. It integrates seamlessly with BENTLY’s 3500 series racks, enabling real-time data acquisition and proactive maintenance for rotating machinery.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Channels | 4 (Analog/digital inputs/outputs) |

| Input Types | Proximity probes, velocity sensors, RTDs |

| Output Voltage | ±10 V DC (Analog), 24 V DC (Digital) |

| Compatibility | BENTLY 3500/44 M vibration monitoring racks |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 241.3 mm × 24.4 mm × 99.1 mm |

| Weight | 0.45 kg |

| Mounting | 3500 rack slot (right-side of interface) |

BENTLY 126599-01

3. Advantages and Features

- Aviation-Grade Durability: Built to withstand high temperatures, shocks, and EMI typical in gas turbine environments.

- Internal Terminations: Simplifies wiring and reduces installation complexity compared to external termination modules.

- Multi-Parameter Support: Simultaneously monitors vibration, displacement, and temperature for comprehensive machinery health assessment.

- Real-Time Data Processing: Enables rapid analysis and alarm triggering via BENTLY’s System 1 software integration.

- Modular Design: Easy to replace or expand within the 3500 series rack system.

4. Application Fields and Case Studies

Industries:

- Energy: Aeroderivative gas turbines in power generation.

- Aerospace: Turbine test stands and auxiliary power units.

- Oil & Gas: Compressor trains and rotating equipment in offshore platforms.

Case Study:

A European power plant adopted the BENTLY 126599-01 to monitor vibrations in its aeroderivative gas turbines. By detecting early-stage bearing wear through real-time data analysis, the module helped reduce unplanned downtime by 25% and extend maintenance intervals by 30%.

A European power plant adopted the BENTLY 126599-01 to monitor vibrations in its aeroderivative gas turbines. By detecting early-stage bearing wear through real-time data analysis, the module helped reduce unplanned downtime by 25% and extend maintenance intervals by 30%.

5. Competitive Comparison

Compared to standard I/O modules, the BENTLY 126599-01 offers:

- Specialized Aviation Design: Optimized for gas turbine applications, unlike generic industrial modules.

- Higher Channel Density: Four channels in a compact form factor, reducing rack space requirements.

- Enhanced Signal Conditioning: Built-in filtering and noise suppression for accurate measurements in high-interference environments.

BENTLY 126599-01

6. Selection Recommendations

- Compatibility: Verify rack type (3500/44 M) and software version (System 1) for seamless integration.

- Environmental Needs: Ensure the module’s -40°C to +85°C temperature range matches operational conditions.

- Redundancy: Consider dual-module configurations for critical turbines to avoid single-point failures.

7. Precautions

- Installation: Follow BENTLY’s guidelines for slot placement (right-side of the interface module) to ensure proper communication.

- Cable Management: Use shielded cables to minimize EMI interference with analog signals.

- Calibration: Regularly verify sensor inputs and update firmware to maintain measurement accuracy.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.