Description

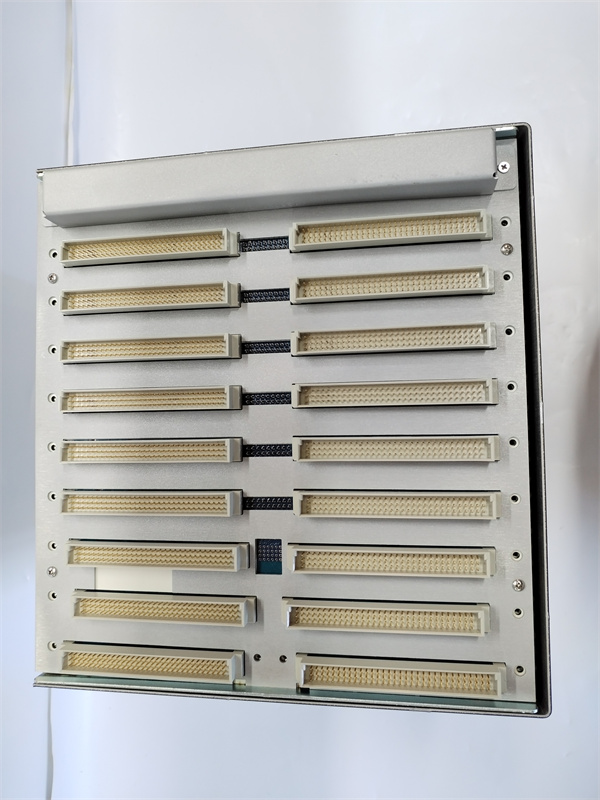

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | 3500/05 |

| Brand | Bentley Nevada |

| Function | Keyphasor Signal Conditioning Module |

| Input Signal | Proximity Probe (AC-coupled, 0.1 to 20 V peak) |

| Frequency Range | 0.1 Hz to 20 kHz |

| Output Signal | TTL-level square wave (0 to 5 V) |

| Power Supply | 18–32 V DC, regulated |

| Power Consumption | Less than 5 W |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Vibration Resistance | 5 g rms (5 to 2000 Hz) |

| Shock Resistance | 50 g peak (11 ms duration) |

| Dimensions | 17.5 mm (width) x 160 mm (height) x 230 mm (depth) |

| Mounting | Rack-mounted in 3500 chassis |

BENTLY 3500/05

3. Advantages and Features

4. Application Areas and Case Studies

- Power Generation: Turbines, generators, and steam systems

- Oil and Gas: Compressors, pumps, and rotating equipment in refineries

- Manufacturing: High-speed motors and industrial machinery

5. Competitive Landscape Comparison

Compared to similar keyphasor modules on the market, the 3500/05 distinguishes itself through its superior noise immunity and adaptability to rapid speed changes. While some alternatives may offer basic signal conditioning, the 3500/05 excels in complex, high-reliability scenarios due to its deep integration with the 3500 system’s comprehensive monitoring ecosystem. Its robust environmental specifications also outperform many competitors, making it a preferred choice for harsh operating conditions.

BENTLY 3500/05

6. Selection Recommendations

- System Compatibility: Ensure your existing setup uses the Bentley Nevada 3500 Machinery Protection System, as this module is designed exclusively for this platform.

- Environmental Requirements: If your application involves extreme temperatures, high vibration, or frequent shocks, the module’s rugged design makes it a strong candidate.

- Performance Needs: For machinery requiring precise speed synchronization or detailed vibration analysis, the 3500/05’s high-frequency response and signal accuracy are critical factors.

- Budget Considerations: While the module represents a premium solution, its long-term reliability and integration benefits offer significant value for mission-critical applications.

7. Usage and Installation Notes

- Installation: Mount the module in a 3500 chassis using proper torque specifications for electrical connections. Ensure grounding complies with industrial safety standards to minimize electromagnetic interference (EMI).

- Calibration: Perform initial calibration with the intended proximity probe to ensure optimal signal conditioning. Regularly verify signal integrity during routine maintenance.

- Safety Compliance: Always power down the system before installing or removing the module. Follow Bentley Nevada’s guidelines for hot-swapping to avoid damage.

- Maintenance: Monitor diagnostic alerts through the 3500 system software to identify potential issues early. Clean the module and chassis periodically to prevent dust or debris buildup.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.