Description

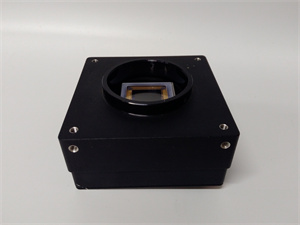

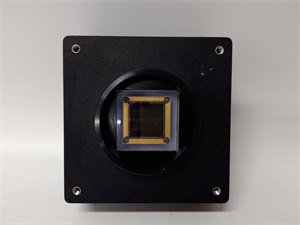

Product Overview

The BASLER A402KC is a high – performance industrial camera developed by BASLER, a globally renowned brand in the field of machine vision. As a key product in BASLER’s extensive machine vision product portfolio, this camera is engineered to meet the diverse and demanding requirements of modern industrial applications. Whether utilized in automated production lines for quality inspection, in logistics for object identification and sorting, or in scientific research for precise image capture, the BASLER A402KC is designed to deliver clear, accurate, and reliable imaging results, thereby enhancing the efficiency and accuracy of various industrial processes.

Built with advanced imaging technology, the BASLER A402KC combines high – resolution imaging with fast frame rates. It is capable of capturing detailed images even in dynamic scenes, making it suitable for applications that require real – time analysis of moving objects. The camera’s user – friendly interface and flexible configuration options allow for easy integration into existing systems, enabling seamless communication with other devices such as image processing units, PLCs, and industrial computers. This makes it an ideal choice for engineers and operators aiming to optimize industrial automation and machine vision applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | BASLER A402KC |

| Manufacturer | BASLER |

| Product Type | Industrial Camera |

| Image Sensor Type | [Specify the sensor type, e.g., CMOS] |

| Resolution | [Specify the resolution, e.g., 2048 x 1536 pixels] |

| Frame Rate | [Specify the frame rate, e.g., Up to 60 frames per second] |

| Pixel Size | [Specify the pixel size, e.g., 5.5 μm x 5.5 μm] |

| Optical Format | [Specify the format, e.g., 1/2.5″] |

| Sensitivity | [Specify the sensitivity value, e.g., High sensitivity in low – light conditions] |

| Interface | [List the interfaces, e.g., GigE Vision, USB 3.0] |

| Power Supply | [Specify, e.g., PoE (Power over Ethernet) or 12 V DC] |

| Operating Temperature Range | 0°C – 50°C |

| Relative Humidity Range | 20% – 80% non – condensing |

| Dimensions | [Specify length × width × height, e.g., 29 mm × 29 mm × 44 mm] |

| Weight | [Specify weight, e.g., 100 g] |

| Compatibility | Compatible with common machine vision software and industrial control systems |

BASLER A402KC

Main Features and Advantages

High – Resolution Imaging

The BASLER A402KC offers high – resolution imaging capabilities, enabling the capture of detailed and sharp images. With its [Resolution value] resolution, it can clearly identify fine details, small defects, and subtle variations in objects, making it highly effective for quality control applications in manufacturing. Whether inspecting the surface of electronic components, detecting flaws in printed circuit boards, or analyzing the texture of materials, the camera provides accurate and reliable image data for precise analysis.

Fast Frame Rate

Equipped with a fast frame rate of up to [Frame rate value], the BASLER A402KC can capture rapid – moving objects without blurring. This feature is crucial for applications such as high – speed production lines, where objects are moving quickly and need to be imaged accurately. The camera’s ability to keep up with fast – paced operations ensures continuous and seamless monitoring, enhancing the efficiency of automated processes.

Excellent Sensitivity

The camera features excellent sensitivity, allowing it to perform well even in low – light environments. Its high – sensitivity sensor can capture clear images with minimal noise, reducing the need for additional lighting in many applications. This not only saves energy but also simplifies the setup process, making it suitable for a wide range of industrial scenarios where lighting conditions may vary.

Flexible Connectivity Options

The BASLER A402KC provides flexible connectivity options with interfaces such as GigE Vision and USB 3.0. These interfaces enable easy integration with various devices and systems, allowing for seamless data transfer and communication. The support for GigE Vision, in particular, enables long – distance data transmission over Ethernet cables, making it convenient for large – scale industrial setups. The camera also supports Power over Ethernet (PoE) functionality, reducing the need for separate power cables and simplifying the installation process.

BASLER A402KC

Application Field

In the manufacturing industry, the BASLER A402KC is widely used for quality inspection on production lines. It can be employed to detect defects in products, verify the correct assembly of components, and ensure product dimensions meet the required specifications. For example, in the automotive industry, it can inspect the quality of engine parts, the alignment of body panels, and the presence of labels and markings. In the electronics manufacturing sector, it can be used to check the soldering quality of circuit boards and the correct placement of components.

In the logistics and warehousing industry, the BASLER A402KC plays a crucial role in object identification and sorting. It can read barcodes, QR codes, and other identification markings on packages and products, enabling automated sorting systems to accurately direct items to their correct destinations. Additionally, it can be used to monitor the movement of goods on conveyor belts, detect abnormalities such as jams or misaligned items, and ensure smooth operation of the logistics process.

For scientific research and medical imaging applications, the BASLER A402KC can be used to capture high – quality images for analysis. In microscopy, it can provide detailed images of cells and tissues for biological research. In non – destructive testing, it can be used to inspect materials and structures for internal defects without causing damage. Its high – resolution and accurate imaging capabilities make it a valuable tool in these fields.

Related Products

- BASLER A405KC: An upgraded version of the BASLER A402KC, the BASLER A405KCmay offer higher resolution, faster frame rates, or improved sensitivity. It is suitable for applications that require even more detailed imaging and higher – performance imaging capabilities, such as advanced quality control in semiconductor manufacturing or high – speed motion analysis.

- BASLER A402KL: A more basic variant, the BASLER A402KLmight have slightly reduced features compared to the BASLER A402KC, such as a lower frame rate or a less sensitive sensor. It serves as a cost – effective option for applications with less demanding imaging requirements, like basic visual inspection in small – scale production facilities.

- BASLER Camera Lenses: A wide range of lenses specifically designed for BASLER cameras, including the BASLER A402KC. These lenses come in different focal lengths, apertures, and optical qualities, allowing users to customize the camera’s field of view, depth of field, and image quality according to their specific application needs.

- BASLER Machine Vision Software: This software is developed to work seamlessly with the BASLER A402KCand other BASLER cameras. It provides a comprehensive set of tools for image acquisition, processing, analysis, and visualization. Features such as image filtering, object recognition, and measurement tools enable users to extract valuable information from the captured images and implement effective machine vision solutions.

- BASLER Camera Mounts and Accessories: A variety of mounts, brackets, and other accessories designed to support the installation and operation of the BASLER A402KC. These accessories include adjustable camera mounts, protective enclosures, and cable management solutions, ensuring the camera is securely installed and operates reliably in different industrial environments.

Installation and Maintenance

Pre – installation preparation: Before installing the BASLER A402KC, carefully read the installation manual provided by BASLER. Ensure that the installation environment meets the specified requirements, including proper lighting conditions, temperature, and humidity. Check the compatibility of the camera with the intended image processing system, computer, or other devices it will be connected to. Prepare all the necessary cables, connectors, and mounting hardware. Make sure to power off all related equipment to avoid electrical hazards during the installation process.

Maintenance recommendations: Regularly clean the camera lens using a suitable lens cleaning solution and a soft, lint – free cloth to remove dust, dirt, and fingerprints, which can affect image quality. Check the camera’s connections, including cables and power supply, to ensure they are secure and free from damage. Periodically update the camera’s firmware as recommended by BASLER to obtain the latest features, performance improvements, and bug fixes. Monitor the camera’s performance during operation, checking for any signs of abnormal behavior such as image distortion, incorrect exposure, or communication errors. In case of any issues, refer to the troubleshooting guide in the user manual or contact BASLER’s technical support team for assistance.

Product Guarantee

BASLER stands firmly behind the quality and reliability of the BASLER A402KC. The industrial camera is covered by a comprehensive quality assurance program, ensuring that it meets strict industry standards. In the event of any manufacturing defects within the warranty period, BASLER offers free repair or replacement services. Their dedicated technical support team is available to answer any questions regarding the installation, operation, and maintenance of the BASLER A402KC. Whether it’s a hardware – related problem or a software – configuration issue, users can rely on BASLER’s professional support to receive timely and effective solutions, reflecting the company’s confidence in the product and its commitment to customer satisfaction in the machine vision market.