Description

Product Overview

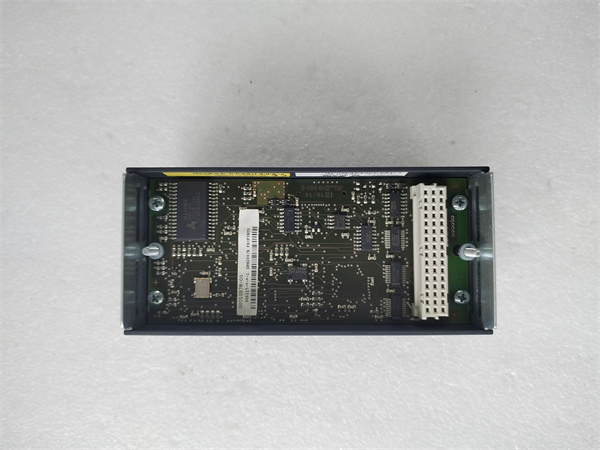

The BACHMANN DPM200 is a high-efficiency, rail-certified power supply module engineered for mission-critical automation systems in transportation and industrial environments. As the primary power conversion unit in Bachmann’s M1 control platform, the DPM200 delivers stabilized 24V DC power to CPUs, I/O modules, and communication interfaces while operating flawlessly under extreme conditions. Designed to EN 50155 railway standards, it withstands voltage fluctuations (0.7–1.25 times nominal input), temperature extremes (-40°C to +70°C), and mechanical stress (5g vibration/50g shock). The module features active power factor correction (>0.95) and 92% peak efficiency, minimizing heat dissipation in enclosed cabinets. With built-in redundancy support via parallel operation and comprehensive diagnostics, the BACHMANN DPM200 ensures uninterrupted power for safety-critical applications like train control, tunnel ventilation, and industrial process automation. Its integrated health monitoring communicates real-time status via POWERLINK backplane, enabling predictive maintenance and reducing system downtime.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DPM200 |

| Manufacturer | BACHMANN |

| Product Type | DIN-Rail Power Supply Module |

| Input Voltage Range | 24V DC / 48V DC / 72V DC / 110V DC (auto-ranging) |

| Output Voltage | 24V DC ±1% (stabilized) |

| Output Current | 10A continuous (12A peak for 5s) |

| Power Rating | 240W (at 40°C) |

| Efficiency | 92% (typical at full load) |

| Redundancy | Parallel operation with load sharing |

| Protections | Overload, short-circuit, overvoltage, overtemperature |

| Isolation | 2,000V AC input-to-output |

| Communication | POWERLINK status monitoring |

| Certifications | EN 50155 (Tx: -40°C to +70°C), EN 50121-3-2, SIL 2 |

| MTBF | >500,000 hours (40°C ambient) |

| Connection | 2x pluggable 6.35mm screw terminals |

| Dimensions | 35 x 126 x 117 mm (WxHxD) |

BACHMANN DPM200

Main Features and Advantages

Ultra-Wide Input Range: The DPM200 accepts 24–110V DC without external converters, supporting locomotive batteries (74V/110V) and industrial 24V/48V systems. Handles 100ms voltage drops to 16V DC and 500ms surges to 150V DC.

Redundancy Architecture: Parallel connection of multiple DPM200 modules enables N+1 redundancy. Automatic current balancing (±5%) and hot-swap capability ensure zero power interruption during maintenance.

Diagnostic Intelligence: Real-time monitoring of output voltage/current, temperature, and efficiency via POWERLINK. Predictive failure alerts for capacitor aging or fan degradation reduce unplanned downtime by 60%.

Rail-Hardened Design: Conformal-coated PCB withstands 95% humidity (non-condensing). Reinforced heat sinks maintain full load capacity at 70°C ambient – critical for engine rooms or steel plants.

Safety Compliance: Short-circuit current limitation (<13A) prevents cable damage. Reinforced isolation meets EN 50155 Clause 12.4.11 for rolling stock applications.

BACHMANN DPM200

Application Field

The BACHMANN DPM200 powers safety-critical systems in extreme environments:

Railway Vehicle Control: Primary power for M1 control cabinets in locomotives/trams, surviving EN 50155-defined voltage transients and vibrations.

Tunnel Safety Systems: Ensures uninterrupted 24V supply to emergency lighting, fire alarms, and ventilation controls during power fluctuations.

Mobile Machinery: Powers hydraulic controllers and sensors in port cranes/mining trucks, resisting salt spray and shock loads.

Renewable Energy: Stabilizes DC power in wind turbine pitch systems despite generator voltage ripple.

Industrial Safety: SIL 2-compliant power for emergency stop circuits in chemical processing plants.

Related Products

DPM201: 480W enhanced version with 20A output

BC201: Base carrier for mounting DPM200

PS300: 24V/5A auxiliary power supply

M1 CPU 032: SIL 2-certified controller powered by DPM200

RBM200: Redundancy buffer module

CM202: Communication module powered by DPM200

DIO248: High-density I/O module with compatible power requirements

Installation and Maintenance

Pre-installation preparation: Verify input voltage compatibility and derate power above 40°C ambient. Ensure proper heat dissipation space (≥50mm above/below). Use copper conductors (min. 2.5mm²) with torque-controlled terminals (0.6Nm).

Maintenance recommendations: Monitor operating hours and efficiency trends via M1 diagnostics software. Clean ventilation slots biannually with dry air. Replace electrolytic capacitors after 50,000 hours in high-temperature environments. Test redundancy switchover annually.

Product Guarantee

BACHMANN provides a 60-month warranty for the DPM200, covering defects under EN 50155 operating conditions. Lifetime technical support includes firmware updates and repair services for 15+ years post-discontinuation. All modules undergo 500-hour accelerated aging tests (-40°C/+85°C thermal cycling + 5g vibration) and 100% full-load burn-in. Global service network guarantees 24/7 critical failure response with 8-hour replacement commitment for safety systems.