Description

Product Overview

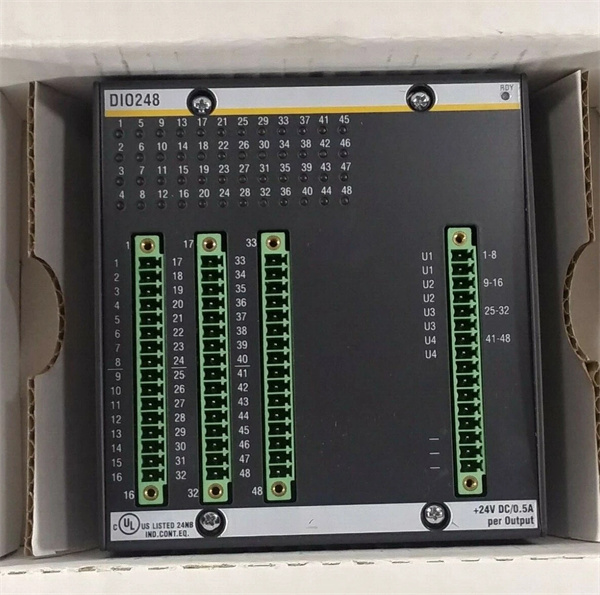

The BACHMANN DIO248 is a high-density hybrid I/O module engineered for space-constrained industrial and railway control applications within Bachmann’s M1 automation platform. Combining 24 digital inputs and 24 digital outputs in a single unit, this module optimizes cabinet space while delivering deterministic performance for safety-critical systems. The DIO248 features galvanic isolation (1,500V AC) between field circuits and the logic backplane, alongside per-channel diagnostics to detect wire breaks, short circuits, and load failures. Designed to EN 50155 railway standards, it operates reliably across extreme temperatures (-40°C to +70°C) and withstands 5g vibrations/50g shocks, making it ideal for rolling stock and mobile machinery. Integration with POWERLINK/CANopen ensures µs-synchronization for real-time control tasks like interlocking and sequence logic. For applications demanding high I/O density without compromising ruggedness, the BACHMANN DIO248 reduces wiring complexity while maintaining SIL 3 functional safety compliance.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | DIO248 |

| Manufacturer | BACHMANN |

| Product Type | 48-Channel Hybrid Digital I/O Module (24 In / 24 Out) |

| Input Specifications | 24x 24V DC (sink/source), 3ms filter, <1mA leakage |

| Output Specifications | 24x 0.5A MOSFET (sourcing), short-circuit protected |

| Isolation | 1,500V AC (field-to-logic), 500V AC (channel groups) |

| Backplane Communication | Ethernet POWERLINK, CANopen |

| Response Time | Inputs: <1ms, Outputs: <0.5ms |

| Load Capacity | 0.5A per channel, 6A total per group |

| Operating Temperature | -40°C to +70°C (EN 50155 TX) |

| Certifications | EN 50155, EN 50121-3-2, SIL 3 (system-dependent) |

| Connection | Dual removable spring-cage terminal blocks |

| Diagnostics | Per-channel LED, wire-break detection, thermal overload |

| Power Consumption | 3.8W (max) |

| Dimensions | 35 x 126 x 117 mm (WxHxD) |

BACHMANN DIO248

Main Features and Advantages

Space Optimization: With 48 channels in one module slot, the DIO248 reduces cabinet footprint by 60% compared to discrete I/O solutions. Dual-terminal blocks simplify wiring for high-density applications like train door control or conveyor systems.

Rail-Hardened Reliability: Conformal-coated PCBs and vibration-resistant connectors exceed EN 61373 Category 1 standards. The DIO248 operates continuously at 70°C ambient temperature – critical for locomotive engine compartments or steel mills.

Intelligent Diagnostics: Real-time monitoring detects open circuits, output shorts, and overloads before failures occur. Timestamped events sync with M1 controllers for predictive maintenance, reducing downtime by up to 45%.

Flexible Configuration: Inputs support wetting voltages from 12-48V DC. Outputs feature configurable slew-rate control to minimize EMI. Group isolation (8 channels/group) allows mixed voltage applications.

Safety Integration: When paired with SIL 3-certified M1 CPUs, the DIO248 enables safety functions like emergency stop chains with <15ms reaction time. Hot-swap capability ensures maintenance without system shutdown.

BACHMANN DIO248

Application Field

The BACHMANN DIO248 excels in high-I/O-density environments requiring rugged performance:

Railway Rolling Stock: Controls passenger door interlocks, lighting circuits, and brake indicators on trams/metro trains (EN 50155 compliance essential).

Material Handling: Manages conveyor belt motor starters, photoelectric sensors, and sorting gate actuators in warehouses.

Tunnel Control Systems: Interfaces with emergency lighting, fan controls, and fire dampers in high-temperature environments.

Mobile Machinery: Operates hydraulic valve solenoids and position sensors on port cranes despite salt spray and vibration.

Manufacturing Automation: Sequences pneumatic cylinders and safety mats in automotive assembly SIL 2 applications.

Related Products

DIO232: 32-channel hybrid module (16 in/16 out) for mid-density needs

BS207: Dedicated 16-channel digital input module

BS208: 16-channel digital output counterpart

M1 CPU 052: High-performance controller for complex I/O systems

BC201: Base carrier for DIO248 module installation

PS310: 24VDC/10A EN 50155 power supply

CM202: Communication module for network integration

Installation and Maintenance

Pre-installation preparation: Ensure DIN rail mounting surface is flat (<0.5mm deviation). Segregate input/output wiring in separate conduits per EN 50121-3-2 EMC requirements. Verify load currents per group (<6A total).

Maintenance recommendations: Monitor channel utilization and temperature via M1 Diagnostics software quarterly. Clean terminal blocks annually with non-residue contact cleaner. Replace modules exhibiting >5% failed channels. Always discharge static before handling the DIO248.

Product Guarantee

BACHMANN offers a 36-month warranty covering defects under EN 50155 operating conditions. Lifetime firmware updates and 15-year repair support ensure long-term system compatibility. All DIO248 modules undergo 96-hour burn-in testing (-40°C/+85°C thermal cycling + 5-500Hz vibration). Global technical support provides SIL compliance documentation and 24/7 critical failure response with guaranteed 4-hour escalation.