Description

Product Overview

The BACHMANN BS207 is a robust digital input module designed for mission-critical railway and industrial automation applications within Bachmann’s modular M1 Control System platform. Engineered to operate in harsh environments, this module reliably acquires discrete signals from sensors, switches, and safety devices across 16 channels. The BS207 features galvanic isolation per channel (up to 1500V AC) to prevent ground loops and electrical noise interference, ensuring signal integrity in electrically noisy rail or industrial settings. As part of Bachmann’s SIL 4-certified safety architecture, it supports redundant configurations and meets EN 50155/50121 railway standards for shock, vibration, and temperature extremes. The module integrates seamlessly with Bachmann’s M1 CPUs via deterministic CANopen or Ethernet POWERLINK backplanes, enabling real-time diagnostics and predictive maintenance. For rail operators and industrial plants, the BACHMANN BS207 delivers uncompromising reliability in safety functions like door control, brake monitoring, and emergency stop systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | BS207 |

| Manufacturer | BACHMANN |

| Product Type | 16-Channel Digital Input Module |

| Input Voltage Range | 24V DC (18–36V) |

| Input Type | Sink/Source (configurable) |

| Isolation | 1500V AC channel-to-channel & channel-to-backplane |

| Response Time | < 1 ms |

| Power Consumption | 1.8W (typical) |

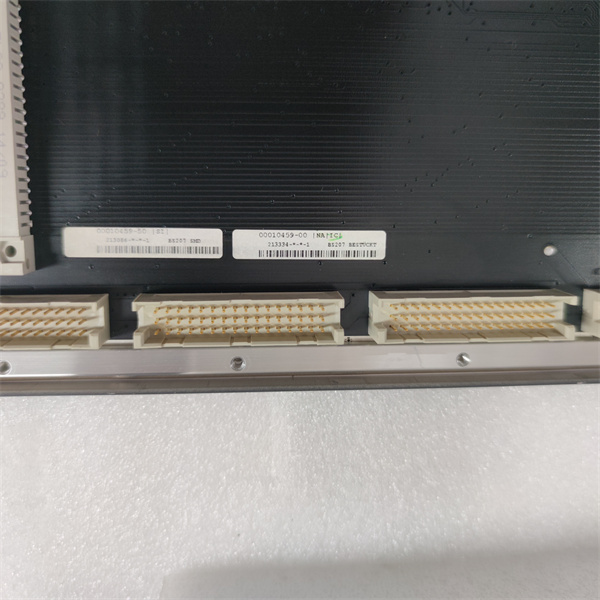

| Connection Interface | Removable screw terminal block |

| Operating Temperature | -25°C to +70°C |

| Certifications | EN 50155, EN 50121-3-2, SIL 4 (via system architecture) |

| Backplane Communication | CANopen / Ethernet POWERLINK |

| MTBF | > 500,000 hours (at 40°C) |

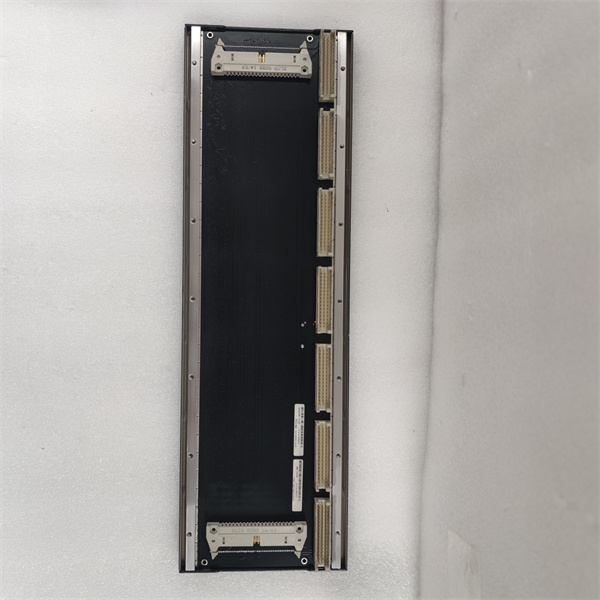

| Dimensions | 35 x 126 x 117 mm (WxHxD) |

BACHMANN BS207

Main Features and Advantages

Extreme Environmental Resilience: The BS207 operates flawlessly in temperature ranges from -25°C to +70°C and withstands 5g vibration/50g shock (EN 61373), making it ideal for rolling stock or heavy machinery. Its conformal-coated PCB resists humidity, dust, and chemical corrosion.

Safety-Critical Design: With per-channel isolation and SIL 4 compliance (when used with certified M1 CPUs), the module detects wire breaks, short circuits, and external supply faults. Redundant BS207 configurations enable hot-swap maintenance without system downtime.

Diagnostic Intelligence: Integrated health monitoring tracks input state changes in sub-millisecond resolution. Event logs with timestamps sync via POWERLINK for predictive maintenance, reducing troubleshooting time by 60%.

Deployment Flexibility: The BS207 supports mixed voltage groups (8 channels per group) and offers LED per-channel status indication. Its tool-free terminal blocks accelerate wiring in confined spaces, while auto-addressing simplifies expansion.

Application Field

The BACHMANN BS207 excels in transportation and heavy industries demanding fail-safe operation. In railway systems, it monitors door interlocks, brake cylinder pressure switches, and emergency buttons on locomotives/metro trains (EN 50155 compliance is mandatory). For industrial safety, the module interfaces with emergency stop circuits, light curtains, and gas detection sensors in SIL 3/4 plants like chemical processing or power generation.

In port automation, the BS207 acquires crane limit switch and spreader lock statuses despite saltwater corrosion. Mining operations leverage its vibration resistance for conveyor belt slip monitoring and pump fault detection. Tunnel ventilation systems use the module’s wide temperature tolerance to control damper actuators in high-heat environments.

BACHMANN BS207

Related Products

BS208: 16-channel digital output counterpart to the BS207

M1 CPU XX: Central processing units (e.g., M1 CPU 020) for system integration

BC201: Backplane carrier module for housing BS207

PM251: 24V power supply with EN 50155 certification

AT300: Rail-certified touch panel for HMI visualization

PL300: Ethernet POWERLINK interface module

Installation and Maintenance

Pre-installation preparation: Verify rail vehicle/panel grounding meets EN 50121-3-2. Use shielded cables (min. 0.25mm²) with separate conduits for high-voltage wiring. Apply anti-vibration mounts in rolling stock installations.

Maintenance recommendations: Perform annual contact resistance checks on terminal blocks. Monitor channel error counters via M1 Diagnostics Manager software. Replace modules showing >5% input deviation. Always use static-safe tools when handling the BS207. Store spares in original ESD packaging at <80% humidity.

Product Guarantee

BACHMANN provides a 36-month warranty for the BS207, covering defects in materials and workmanship under EN 50155 operating conditions. The company offers lifetime product support, including firmware updates and repair services for 15+ years after discontinuation. Global technical assistance includes 24/7 hotline support for safety-critical failures, with optional on-site commissioning packages. All BACHMANN BS207 modules undergo 100% burn-in testing at extreme temperatures prior to shipment.