Description

Product Overview

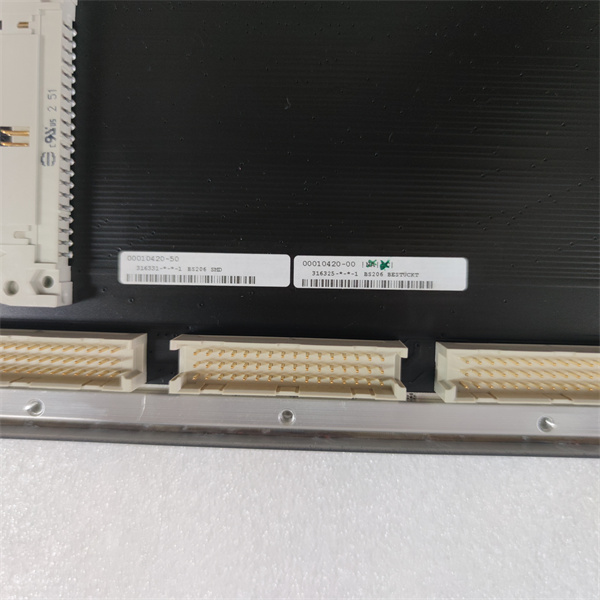

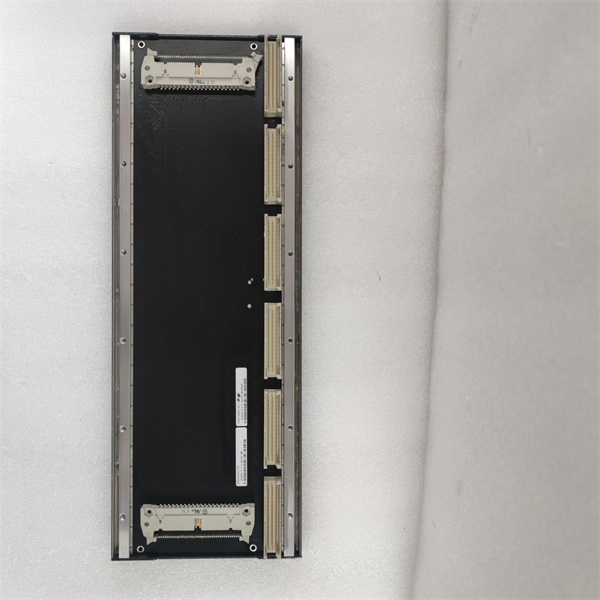

The BACHMANN BS206 is a high-precision analog input module engineered for critical measurement and control tasks within Bachmann’s M1 railway and industrial automation platforms. Designed to operate in extreme environments, this 16-channel module acquires signals from sensors (temperature, pressure, flow, etc.) with exceptional accuracy, making it indispensable for safety-related systems. The BS206 features galvanic isolation (1500V AC per channel) and complies with stringent EN 50155 railway standards for shock, vibration, and temperature resilience (-40°C to +70°C). Its dual-range capability supports both voltage (0-10V) and current (4-20mA) inputs simultaneously, while integrated diagnostics detect wire breaks, sensor faults, and out-of-range values in real time. When integrated with SIL 4-certified M1 controllers, the BACHMANN BS206 enables predictive maintenance through continuous signal trending and timestamped event logging. For rolling stock and industrial processes demanding metrological reliability, this module delivers uncompromising performance in traction control, energy management, and safety monitoring applications.

Technical Specifications

| Parameter Name | Parameter Value |

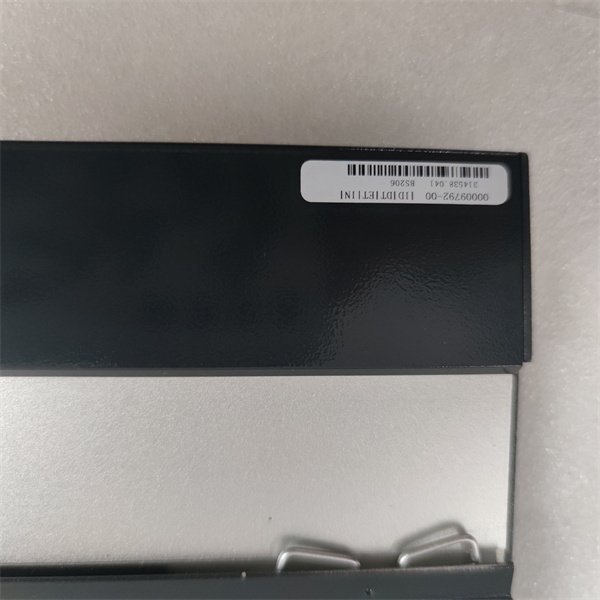

| Product Model | BS206 |

| Manufacturer | BACHMANN |

| Product Type | 16-Channel Analog Input Module |

| Input Ranges | 0-10V DC / 4-20mA (configurable per channel) |

| Resolution | 16-bit |

| Accuracy | ±0.1% full scale (25°C) |

| Isolation | 1500V AC channel-to-channel & channel-to-backplane |

| Sampling Rate | 100 samples/sec (all channels) |

| Common Mode Rejection | >120 dB at 50/60 Hz |

| Connection | Removable screw terminal block |

| Operating Temperature | -40°C to +70°C |

| Certifications | EN 50155, EN 50121-3-2, SIL 3 |

| Communication | Ethernet POWERLINK/CANopen |

| Power Consumption | 2.5W (typical) |

| Dimensions | 35 x 126 x 117 mm (WxHxD) |

BACHMANN BS206

Main Features and Advantages

Metrological Excellence: The BS206 achieves ±0.1% baseline accuracy with 16-bit resolution and <0.5µV/°C drift, ensuring precise measurement in fluctuating temperatures. Auto-calibration routines compensate for long-term drift, reducing maintenance interventions by 50%.

Rail-Optimized Robustness: Conformal-coated PCBs and vibration-resistant connectors (EN 61373 certified) withstand 5g/10-150Hz vibrations and 50g shocks. Operating at -40°C to +70°C, the BS206 performs reliably in Arctic mining or desert rail applications.

Advanced Diagnostics: Each channel continuously monitors signal integrity, triggering alerts for underrange/overrange conditions, sensor wire breaks, or shunt detection. Timestamped fault logs synchronize with control CPUs via POWERLINK for rapid root-cause analysis.

Configuration Flexibility: Channels operate in 8-channel groups with independent range selection (voltage/current mix). The BS206 supports software-configurable filtering (1-100Hz) for noise suppression in electrified environments. Hot-swappable design enables replacement without system shutdown.

Application Field

The BACHMANN BS206 is deployed in transportation and industrial scenarios requiring certified measurement integrity. In rail systems, it monitors traction battery voltages, brake cylinder pressures, and HVAC temperatures on high-speed trains (EN 50155 compliance essential). For power generation, the module acquires turbine bearing temperatures and vibration levels in SIL 3-certified safety loops.

Industrial process plants utilize the BS206 for reactor vessel level monitoring and chemical dosing control, leveraging its 4-20mA HART pass-through capability. In renewable energy, it measures DC link voltages in solar inverters and wind turbine pitch systems. Tunnel safety systems rely on its ±0.1% accuracy for critical airflow velocity monitoring.

BACHMANN BS206

Related Products

BS207: 16-channel digital input module for discrete signals

BS208: Digital output counterpart with relay/transistor options

M1 CPU 032: SIL 4-certified controller for safety systems

BC201: Base carrier for BS206 module mounting

PS300: EN 50155-certified 24VDC power supply

AI300: Signal conditioner for thermocouples/RTDs

Installation and Maintenance

Pre-installation preparation: Ensure DIN rail grounding meets EN 50121-3-2. Segregate analog cables from power lines using separate metallic conduits. Verify sensor loop resistance (<600Ω for 4-20mA) before connection.

Maintenance recommendations: Perform biennial calibration verification using certified references. Monitor channel “health index” via M1 Diagnostics Manager software. Clean terminal blocks annually with contact spray to prevent oxidation. Replace modules showing >1% accuracy deviation.

Product Guarantee

BACHMANN provides a 36-month warranty covering defects under EN 50155 operating conditions. The company offers lifetime firmware updates and 15+ years of repair services post-discontinuation. All BS206 modules undergo 72-hour burn-in testing at temperature extremes (-40°C/+85°C) and vibration simulation. Global technical support includes SIL compliance documentation and 24/7 critical failure response.