Description

Detailed Parameter Table

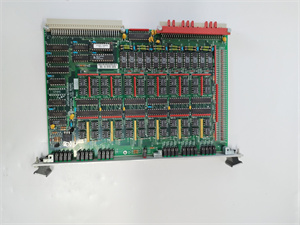

| Parameter Name | Parameter Value |

|---|---|

| Product model | AMAT 0100-76124 |

| Manufacturer | Applied Materials (AMAT) |

| Product category | Digital Input/Output (I/O) Board |

| Input voltage range | 24V DC ±10% |

| Operating frequency | 47-63 Hz |

| Output voltage | +5V, +15V, -15V, +24V regulated DC |

| Number of channels | 16-channel, non-isolated |

| Input signal type | 4 to 20 mA |

| Communication protocols | Modbus/TCP, Modbus/RTU, EtherNet/IP, CC-Link family SLMP |

| Interface | Standard Ethernet |

| Operating temperature | -10°C to +60°C |

| Storage temperature | -40°C to +85°C |

| Humidity | 10 to 90% RH, non-condensing |

| Protection class | IP54 |

| Dimensions | 25 cm x 15 cm x 3 cm |

| Weight | 1 kg |

| Certifications | CE, RoHS, UL compliant |

AMAT 0100-76124

Product Introduction

The AMAT 0100-76124 is a high-performance digital input/output (I/O) board designed for demanding industrial automation applications. It is part of Applied Materials’ extensive lineup of automation products, known for their reliability and advanced technology. This module is used in semiconductor manufacturing processes, particularly in the Centura/Endura series machines.

Core Advantages and Technical Highlights

High Precision and Reliability: The AMAT 0100-76124 offers robust performance and reliability, ensuring stable operation of control modules in various industrial applications.

Flexible Configuration: The unit supports multiple digital input and output channels, providing scalable power distribution and communication capabilities.

Advanced Communication: The unit supports multiple communication protocols, including Modbus/TCP, Modbus/RTU, EtherNet/IP, and CC-Link family SLMP, facilitating integration with existing industrial networks.

User-Friendly Design: The rear-mounted design of the AMAT 0100-76124 allows for easy integration into standard industrial control cabinets, simplifying installation and maintenance.

Industrial Environmental Tolerance: The module is designed to operate stably in harsh environments, such as high-temperature welding workshops and corrosive painting workshops.

Multi-Dimensional Data Fusion Management: The module can integrate multiple data fields and transmit them in real-time to the MES system, enabling full-link visualization of production status.

Modular Expansion Compatibility: The AMAT 0100-76124 provides a standardized VME bus interface, compatible with semiconductor equipment platforms like AMAT P5000 and Endura 5500.

Maintenance-Friendly Design: The module supports hot-swap replacement and remote OTA firmware upgrades, reducing production line downtime.

AMAT 0100-76124

Typical Application Scenarios

The AMAT 0100-76124 is widely used in various industrial sectors, including:

-

Semiconductor Manufacturing: Used in CVD equipment for real-time control and data processing.

-

Automotive Welding Line: Installed on tooling boards to collect welding process status and verify the matching of the body VIN code and production plan.

-

Semiconductor Wafer Transmission: Integrated into robot arms to monitor the flow path of wafer carriers in etching/CVD chambers.

Related Model Recommendations

-

AMAT 0100-71271: A related module with similar control capabilities.

-

AMAT 0100-71311: Another module suitable for similar applications.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the AMAT 0100-76124, ensure that the environment meets the specified requirements, including an operating temperature range of -10°C to +60°C. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard 483 mm (19-in.) cabinet for secure installation.

Maintenance Suggestions

To maintain the AMAT 0100-76124, perform regular inspections of the unit and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance.