Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

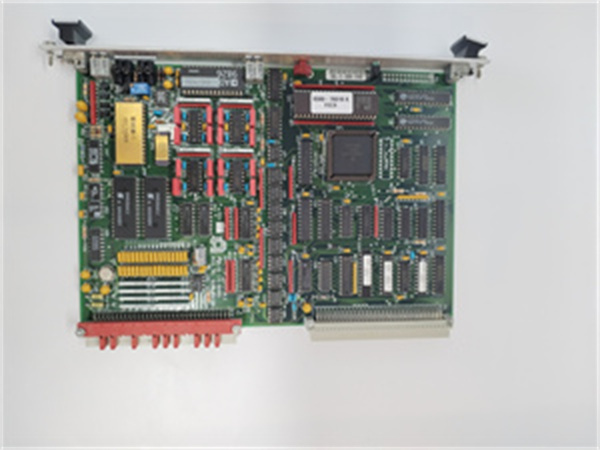

| Product model | AMAT 0100-20100 |

| Manufacturer | Applied Materials (AMAT) |

| Product category | Analog Input/Output Board |

| Description | PCB assembly for analog input/output operations |

| Operating Voltage | 24V DC |

| Memory Size | 16 MB SDRAM, 32 MB Flash |

| Power Consumption | Maximum 8.5W per non-fault-tolerant module |

| Operating Temperature Range | 0°C to +60°C |

| Dimensions (W x H x D) | 14.7 cm x 5.15 cm x 11.4 cm |

| Weight | 0.6 kg |

| Communication | RS232, VMEbus |

| Certifications | SEMI S2, SEMI F47, CE |

| Compatibility | Compatible with AMAT P5000 systems |

AMAT 0100-20100

Product Introduction

The AMAT 0100-20100 is an analog input/output (AI/O) board manufactured by Applied Materials (AMAT). It is a key component in the semiconductor manufacturing process, used for precise control and monitoring of analog signals in various semiconductor fabrication equipment.

Core Advantages and Technical Highlights

High Precision:

-

Ensures reliable and high-quality analog signal processing and transmission.

Durability:

-

Built to withstand harsh industrial environments, ensuring long-term reliability.

Compatibility:

-

Compatible with various Applied Materials systems, ensuring seamless integration into existing setups.

User-Friendly Design:

-

Easy to install and integrate, reducing downtime and improving overall productivity.

AMAT 0100-20100

Typical Application Scenarios

The AMAT 0100-20100 is widely used in various semiconductor manufacturing processes:

-

Wafer Inspection: Facilitates precise control during wafer inspection processes.

-

Process Monitoring: Used in monitoring systems to ensure precise control and visualization of semiconductor processes.

-

Equipment Control: Supports analog signal processing for controlling and monitoring semiconductor fabrication equipment.

Related Model Recommendations

-

AMAT P5000 System: The primary system that the 0100-20100 is designed to support.

-

AMAT 0100-09145: Video interconnect board for additional process control and monitoring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

-

Ensure the environment meets the specified temperature and humidity requirements (0°C to +60°C). Use shielded cables and proper grounding to minimize electromagnetic interference.

Maintenance Suggestions:

-

Regularly inspect connections for wear and clean the module with a static-free cloth to ensure optimal heat dissipation. Perform annual full calibration and quarterly leak checks (He mass spec recommended). Replace O-rings every 2 years and verify ground connections (impedance <1Ω).

Service and Guarantee Commitment

Applied Materials stands behind the quality and reliability of the 0100-20100, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Their dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations.