Description

Detailed Parameter Table

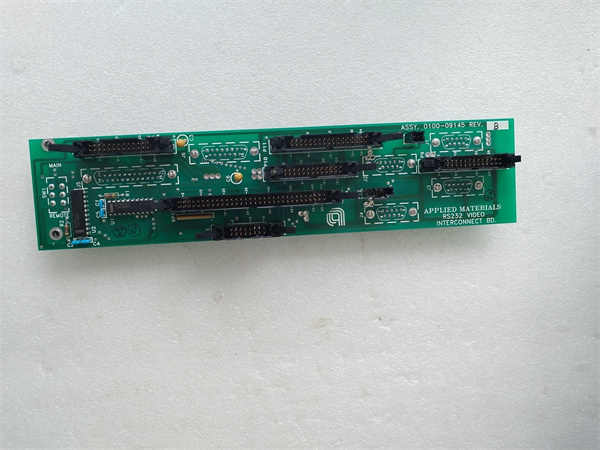

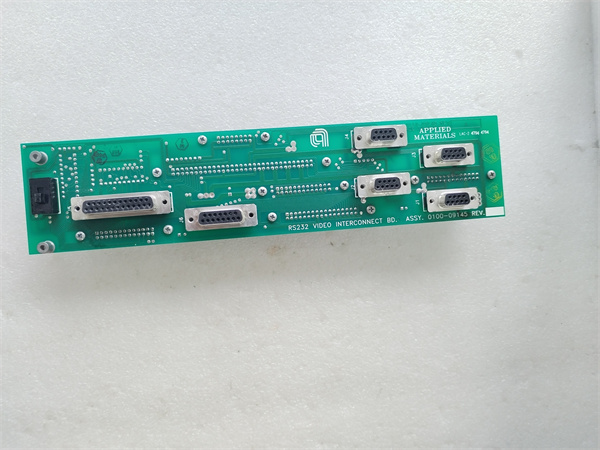

| Parameter Name | Parameter Value |

|---|---|

| Product model | AMAT 0100-09145 |

| Manufacturer | Applied Materials (AMAT) |

| Product category | Video Interconnect PCB |

| Description | RS232 Video Interconnect Board Assembly |

| Operating Voltage | 24V DC |

| Communication | RS232 |

| Dimensions (W x H x D) | 14.7 cm x 5.15 cm x 11.4 cm |

| Weight | 0.6 kg |

| Operating Temperature Range | 0°C to +60°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Certifications | SEMI S2, SEMI F47, CE |

| Compatibility | Compatible with AMAT P5000 systems |

AMAT 0100-09145

Product Introduction

The AMAT 0100-09145 is a high-precision video interconnect PCB assembly designed for use in semiconductor manufacturing processes. It is part of the AMAT P5000 system and is used to facilitate RS232 communication and video signal processing in various semiconductor fabrication equipment.

Core Advantages and Technical Highlights

High Precision:

-

Ensures reliable and high-quality video signal processing and transmission.

Durability:

-

Built to withstand harsh industrial environments, ensuring long-term reliability.

Compatibility:

-

Compatible with various Applied Materials systems, ensuring seamless integration into existing setups.

User-Friendly Design:

-

Easy to install and integrate, reducing downtime and improving overall productivity.

AMAT 0100-09145

Typical Application Scenarios

The AMAT 0100-09145 is widely used in various semiconductor manufacturing processes:

-

Wafer Inspection: Facilitates video signal processing during wafer inspection processes.

-

Process Monitoring: Used in monitoring systems to ensure precise control and visualization of semiconductor processes.

-

Equipment Control: Supports RS232 communication for controlling and monitoring semiconductor fabrication equipment.

Related Model Recommendations

-

AMAT P5000 System: The primary system that the 0100-09145 is designed to support.

-

AMAT 0100-09123: Wafer Sensor Board for additional process control and monitoring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

-

Ensure the environment meets the specified temperature and humidity requirements (0°C to +60°C, 5% to 95% RH non-condensing). Use shielded cables and proper grounding to minimize electromagnetic interference.

Maintenance Suggestions:

-

Regularly inspect connections for wear and clean the module with a static-free cloth to ensure optimal heat dissipation. Perform annual full calibration and quarterly leak checks (He mass spec recommended). Replace O-rings every 2 years and verify ground connections (impedance <1Ω).

Service and Guarantee Commitment

Applied Materials stands behind the quality and reliability of the 0100-09145, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Their dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations.