Description

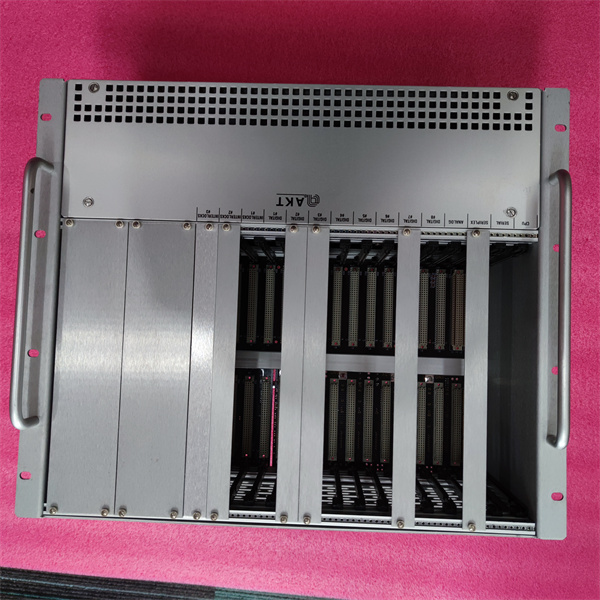

Product Overview

The Aventics AKT 0100-71275 is a high-reliability pneumatic solenoid valve engineered for precision fluid control in industrial automation systems. As a key component of Aventics’ (now part of Emerson) AKT series, this 5/2-way valve delivers exceptional performance in demanding applications requiring rapid switching and energy efficiency. The AKT 0100-71275 features a compact, modular design with direct mounting capability, enabling seamless integration into valve manifolds while optimizing space in control cabinets. Its corrosion-resistant thermoplastic housing withstands harsh environments, including exposure to oils, chemicals, and temperature extremes. The valve’s low power consumption (1.2W DC) reduces operational costs, while the pressure range of 0.15-1.0 MPa accommodates diverse pneumatic circuits. With a lifespan exceeding 100 million cycles, the Aventics AKT 0100-71275 minimizes maintenance downtime in continuous production environments. Its swift ≤10ms response time ensures precise actuator control for robotics, clamping, and positioning systems.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | AKT 0100-71275 |

| Manufacturer | Aventics (Emerson) |

| Product Type | 5/2-Way Solenoid Valve |

| Port Size | G1/4 |

| Operating Pressure | 0.15–1.0 MPa |

| Voltage Options | 24V DC, 110V AC, 230V AC |

| Power Consumption | 1.2W (DC), 2.2VA (AC) |

| Response Time | ≤10 ms |

| Flow Rate (Cv) | 1.6 |

| Operating Temperature | -10°C to +60°C |

| Ambient Temperature | -10°C to +50°C |

| Protection Class | IP65 |

| Housing Material | Glass-Fiber Reinforced Thermoplastic |

| Seal Material | NBR |

| Weight | 0.25 kg |

AKT 0100-71275

Main Features and Advantages

Energy-efficient operation: The Aventics AKT 0100-71275 utilizes low-power solenoids with thermal overload protection, reducing energy costs by up to 85% compared to conventional valves. Its optimized flow path minimizes pressure drop, enhancing system efficiency.

Robust construction: Featuring corrosion-resistant housing and NBR seals, the valve operates reliably in environments with coolants, oils, and mild chemicals. The IP65 rating ensures dust-tight and water-jet resistant performance.

Modular flexibility: Compatible with Aventics’ V04A manifold system, the AKT 0100-71275 supports tool-free mounting and individual replacement without depressurizing adjacent valves. Fieldbus connectivity options (PROFIBUS, CANopen via adapters) enable Industry 4.0 integration.

High-speed precision: With ≤10ms switching times and 1.6 Cv flow capacity, the valve delivers precise pneumatic control for high-cycle applications. Its bistable latching versions maintain position during power loss, enhancing safety.

Application Field

The Aventics AKT 0100-71275 excels in automated manufacturing requiring rapid pneumatic sequencing. In automotive production, it controls robotic welding clamps and conveyor stoppers with millisecond precision. For packaging lines, the valve drives filling heads and sealing mechanisms, handling up to 120 cycles/minute.

In semiconductor fabrication, its cleanroom-compatible variants operate vacuum grippers in wafer handling systems. Food processing plants utilize the AKT 0100-71275 for sanitary conveyor control, where IP65 protection withstands high-pressure washdowns. Material handling applications include palletizer cylinder sequencing and AS/RS shuttle positioning. Recent innovations see this valve deployed in renewable energy equipment, controlling hydraulic pitch systems in wind turbines.

AKT 0100-71275

Related Products

AKT 0100-71270: 3/2-way version for single-acting cylinders

AKT 0100-71276: 5/3-way variant with exhaust center position

AKT-8M: 8-station manifold base for valve grouping

AKT-ASI: AS-Interface communication module

AKT-PB: PROFIBUS DP adapter

AKT-24DC-S: SIL 3 certified solenoid coil

V04A-G1/4: G1/4 manifold mounting plate

Installation and Maintenance

Pre-installation preparation: Verify air supply filtration (40μm minimum) and dew point below +3°C. For manifold mounting, align the AKT 0100-71275 with V04A groove system and secure with 0.7–1.0 Nm torque. Maintain 50mm clearance for coil heat dissipation.

Maintenance recommendations: Inspect seals biannually for compression set; replace if hardness exceeds 80 Shore A. Clean valve cores annually with oil-free compressed air. Test electrical continuity during preventive maintenance. The Aventics AKT 0100-71275 enables single-valve replacement without manifold disassembly.

Product Guarantee

Emerson provides a 24-month warranty for the AKT 0100-71275, covering material and manufacturing defects. Each valve undergoes 100% cycle testing at 1.5x rated pressure before shipment. Global technical support offers 48-hour response for critical failures, with lifetime access to CAD models and fluid simulation tools via Emerson’s online portal.