Description

Product Overview

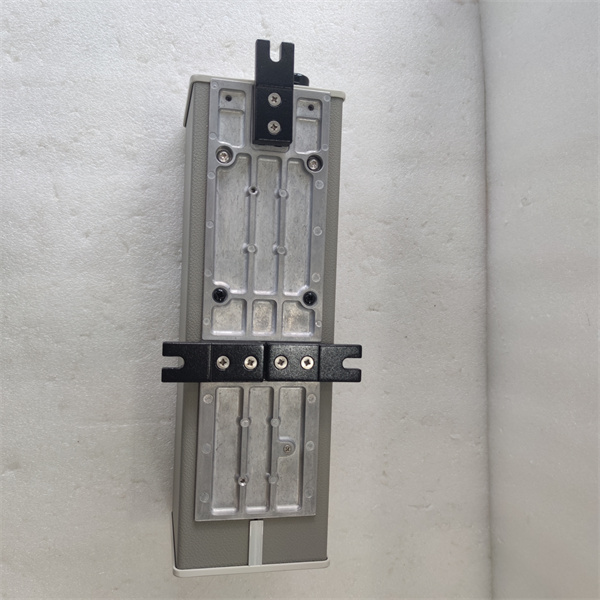

The Agilent 5517C is a high-precision laser displacement measurement system designed for metrology-grade calibration and alignment in industrial and research environments. As part of Agilent Technologies’ legacy laser interferometer portfolio (now Keysight Technologies), this dual-frequency HeNe laser system delivers nanometer-level accuracy for positioning, straightness, and angular error compensation in CNC machines, coordinate measuring machines (CMMs), and semiconductor lithography equipment. The 5517C utilizes heterodyne interferometry to achieve ±0.03 ppm measurement uncertainty, making it indispensable for applications demanding sub-micron traceability. Its modular architecture supports up to seven measurement axes simultaneously, while environmental compensation sensors automatically correct for temperature, humidity, and air pressure variations. The Agilent 5517C remains a benchmark in precision manufacturing, enabling ISO 17025-compliant calibrations for aerospace, optics, and advanced machinery sectors.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | 5517C |

| Manufacturer | Agilent Technologies (Keysight) |

| Product Type | Laser Calibration System |

| Laser Type | Dual-Frequency HeNe (633 nm) |

| Measurement Uncertainty | ±0.03 ppm |

| Measurement Range | Up to 80 m (with beam extenders) |

| Linear Resolution | 1.24 nm (λ/512) |

| Max Axes Supported | 7 simultaneous |

| Environmental Compensation | Integrated temp/humidity/pressure sensors |

| Output Interfaces | RS-232, IEEE-488 (GPIB) |

| Warm-up Time | <15 minutes |

| Beam Diameter | 4 mm (expander compatible) |

| Power Requirements | 100–240V AC, 50/60Hz |

| Operating Temperature | 15°C to 35°C |

| Dimensions (Laser Head) | 225 × 140 × 110 mm |

AGILENT 5517C

Main Features and Advantages

Ultimate metrological traceability: The Agilent 5517C achieves NIST-traceable measurements through stabilized Zeeman-split frequencies, maintaining accuracy over years of operation. Its dynamic environmental compensation corrects refractive index errors in real-time, ensuring reliable data in fluctuating workshop conditions.

Multi-axis versatility: Configured with modular optics (linear, angular, straightness, flatness), the system performs 6-DOF error mapping on machine tools. The heterodyne design eliminates measurement dead zones, enabling uninterrupted data capture during axis reversals.

Operational efficiency: Quick-start capability reduces warm-up delays, while remote control via GPIB/RS-232 supports automated calibration sequences. The split-frequency architecture inherently rejects common-mode noise, allowing stable operation near motors and drives. For legacy integration, the Agilent 5517C maintains backward compatibility with HP/Agilent 552x-series optics and software.

Application Field

The Agilent 5517C is deployed where uncompromised precision defines operational success. In semiconductor fabs, it calibrates stepper lens alignment systems to sub-arcsecond angular accuracy. Aerospace manufacturers rely on it for airframe jig calibration and turbine blade inspection fixtures.

For optical engineering, the system validates telescope mirror grinding machines and freeform lens generators. Automotive OEMs use the 5517C to certify CMMs for powertrain component inspection. Recent applications include additive manufacturing, where it maps thermal distortion in metal 3D printers. The Hubble Space Telescope mirror fabrication leveraged predecessor models, underscoring the platform’s pedigree.

AGILENT 5517C

Related Products

10780C: Retroreflector kit for linear displacement

10706A: Angular interferometer optics

10717A: Straightness measurement adapter

5529A: Air sensor for environmental compensation

10897B: TriOptics alignment package

Keysight 5530: Successor model with enhanced dynamics

Agilent 5519A: Vibration-isolated base for metrology labs

Installation and Maintenance

Pre-installation preparation: Establish vibration-isolated mounting (≥0.5 Hz resonance). Verify air quality – avoid oil mist or particulate-heavy environments. Align beam path below 0.5° angular deviation using alignment telescope.

Maintenance recommendations: Annually clean optical surfaces with anhydrous ethanol and lint-free swabs. Verify laser power output quarterly (nominal 500 µW). Replace HeNe tubes every 20,000 hours. Store optics in nitrogen-purged containers during inactivity. The Agilent 5517C requires recalibration every 24 months at Keysight-accredited labs.

Product Guarantee

Keysight Technologies provides 12-month performance warranty for refurbished 5517C systems, including laser power stability and interferometer linearity verification. All units undergo 72-hour burn-in and NIST-traceable certification. Lifetime technical support includes legacy firmware archives and optical alignment protocols. Calibration certificates comply with ISO/IEC 17025:2017 standards.