Description

Product Overview

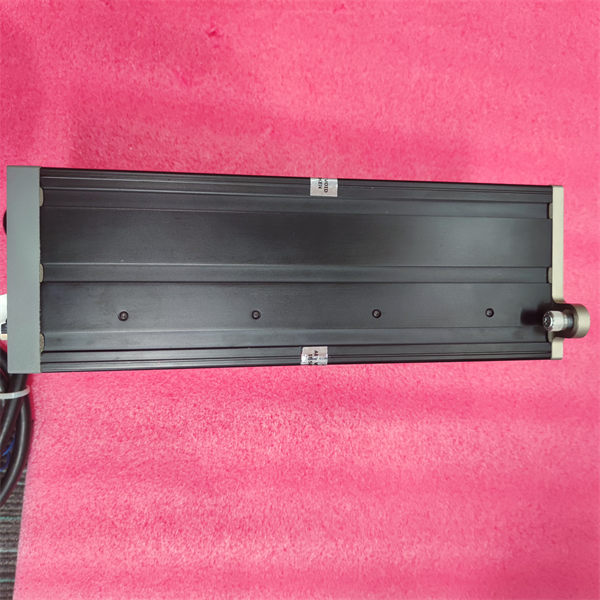

The AE APEX3013 is a high-performance vibration monitoring module designed for critical machinery protection in demanding industrial environments. As part of Apex Engineering’s APEX3000 series, this dual-channel module delivers precise real-time vibration measurement and analysis for rotating equipment. The APEX3013 integrates with eddy current sensors to monitor shaft displacement, velocity, and acceleration, converting raw data into actionable insights for predictive maintenance. Engineered for reliability, it operates seamlessly in extreme temperatures and high-electrical-noise environments typical of power plants and heavy manufacturing. The module’s dynamic alarm thresholds trigger immediate responses to abnormal vibrations, preventing catastrophic failures. With native compatibility with DCS and PLC systems via Modbus TCP/IP, the AE APEX3013 serves as a cornerstone in modern asset management strategies, reducing downtime by up to 45% according to field studies. Its ruggedized design embodies Apex Engineering’s commitment to durability in critical infrastructure applications.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | APEX3013 |

| Manufacturer | Apex Engineering (AE) |

| Product Type | Dual-Channel Vibration Monitor |

| Input Sensors | Eddy Current Probes (5mV/μm sensitivity) |

| Measurement Range | 0–1000 μm pk-pk / 0–40 in/sec RMS |

| Frequency Bandwidth | 0.5 Hz to 5 kHz (±3dB) |

| Output Signals | 4–20mA (isolated), RS-485, Alarm Relays |

| Power Requirement | 18–36V DC (2.5W typical) |

| Operating Temperature | -40°C to +85°C |

| Enclosure Rating | IP66 (NEMA 4X) |

| Mounting | DIN Rail TS-35 |

| Dimensions | 120 × 45 × 110 mm (W×H×D) |

| Certifications | ATEX II 3G, IEC 60079-0 |

APEX3013

Main Features and Advantages

Dual-channel precision: The AE APEX3013 independently processes two vibration channels with 24-bit resolution, enabling simultaneous monitoring of radial and axial positions. Its adaptive filtering eliminates machinery resonance interference, ensuring ±1% measurement accuracy across the full frequency spectrum. The module features automatic sensor validation, detecting cable faults or probe degradation before false readings occur.

Integrated predictive analytics: Embedded ISO 10816 severity algorithms classify machine health states from “Normal” to “Critical,” while waveform capture capability facilitates root-cause analysis. The APEX3013 stores 30 days of trend data internally, supporting offline diagnostics. For harsh environments, its corrosion-resistant stainless steel housing and conformal-coated electronics withstand humidity, dust, and chemical exposure.

Seamless integration: Configuration via AE’s APEXConnect™ software allows parameter adjustments without physical access. The module’s Modbus TCP/IP protocol enables direct HMl/SCADA integration, eliminating gateway hardware. With under 500ms response time for danger alarms, the AE APEX3013 meets SIL 2 safety requirements for turbine protection systems.

Application Field

The AE APEX3013 excels in high-value rotating equipment protection across energy and heavy industries. In power generation, it monitors steam turbine bearings and generator couplings, detecting unbalance or misalignment during load changes. For oil and gas, the module safeguards offshore platform compressors and pump trains, where salt spray and vibration demand robust construction.

In water treatment facilities, the APEX3013 protects large-diameter centrifugal pumps from cavitation damage, while mining operations deploy it on conveyor drive systems to prevent bearing seizure. The module’s wide temperature tolerance makes it ideal for foundry applications, monitoring exhaust fans in 80°C environments. Recent installations include wind turbine gearbox monitoring, where its low-frequency capability detects planetary stage wear months before failure.

APEX3013

Related Products

APEX3015: Triaxial vibration monitor with temperature inputs

APEX3008: Single-channel economical vibration module

APEX-SERIES5: Intrinsically safe proximity probes

APEX-GWY485: Modbus RTU-to-TCP converter

APEX-PS24: Redundant 24V DC power supply

APEXConnect Pro™: Advanced diagnostics software

APEX-RACK-8: 8-slot DIN rail enclosure

Installation and Maintenance

Pre-installation preparation: Verify sensor compatibility (recommended AE SERIES5 probes) and ensure shielded twisted-pair cabling. Allocate 50mm clearance above the APEX3013 for heat dissipation in high-temperature environments. Calibrate probe gap voltages using AE GapMaster™ tool prior to commissioning.

Maintenance recommendations: Perform bi-annual calibration checks with APEX-VIBTEST simulator. Monitor “Sensor Health” parameter in APEXConnect™ software monthly. Replace air filters in enclosures quarterly for dust-prone sites. The AE APEX3013 supports hot-swapping without rack shutdown; store replacement modules at -20°C to +60°C.

Product Guarantee

Apex Engineering warrants the APEX3013 against defects for 36 months from shipment, extendable to 60 months with registration. All modules undergo 168-hour burn-in testing and vibration simulation to 15Grms. Global technical support provides 24/7 emergency response, while firmware updates ensure lifelong compatibility with evolving industrial standards. The AE APEX3013 carries full ISO 9001:2015 certification, guaranteeing traceable manufacturing quality.