Description

Detailed parameter table

| Parameter name | Parameter value |

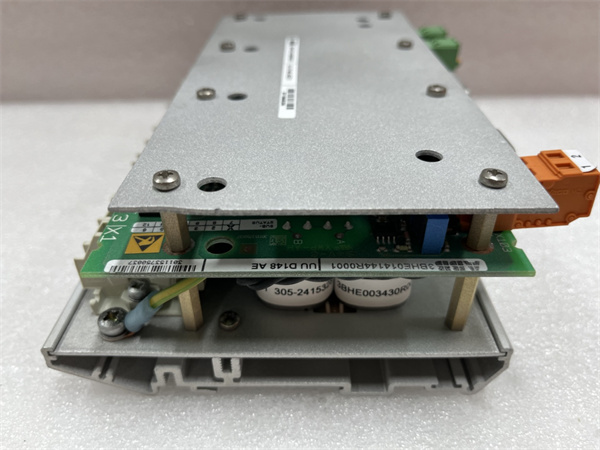

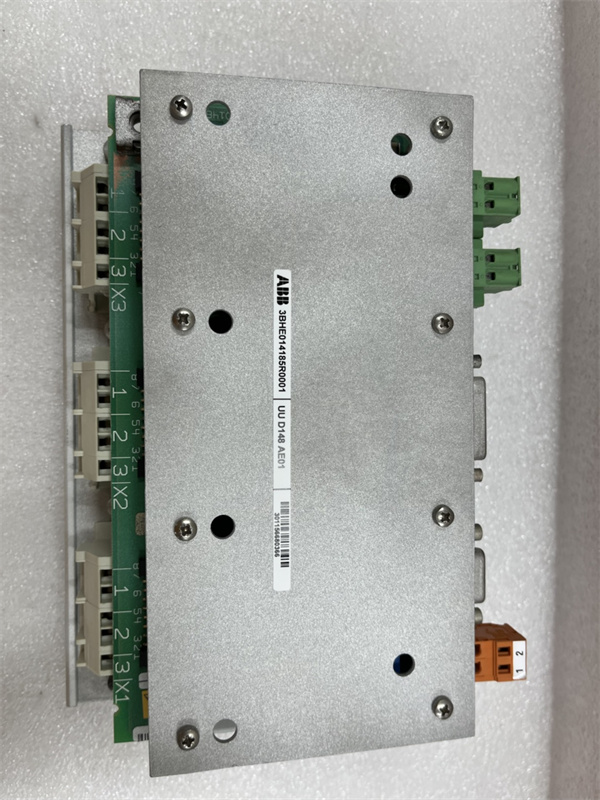

| Product model | UUD148AE01 |

| Manufacturer | ABB |

| Product category | Industrial communication module |

| Dimensions (WxHxD) | Compact design, approximately 120mm x 80mm x 30mm, suitable for installation in limited space |

| Weight | Lightweight, around 0.2kg, easy to handle during installation |

| Mounting | DIN rail mounting, compatible with standard 35mm DIN rails for convenient integration into control cabinets |

| Compatibility | Seamlessly compatible with ABB’s PLC systems, HMIs like HC800, and other industrial control components |

| Operating temperature | -20°C to +60°C, adapting to harsh industrial temperature environments |

| Protection class | IP20, providing protection against dust and accidental contact |

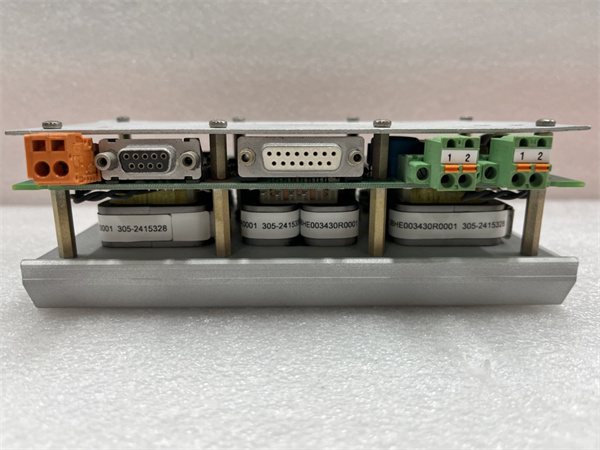

| Communication protocols | Supports Profibus DP, Modbus RTU, ensuring smooth data transmission with various devices |

| Power supply | 24V DC ±10%, power consumption ≤5W |

| Data transfer rate | Up to 12Mbps for high-speed data exchange |

| Isolation | 2.5kV electrical isolation, enhancing anti-interference ability |

ABB UUD148AE01

Product introduction

The ABB UUD148AE01 is a high-performance industrial communication module, serving as a vital bridge for data transmission in industrial automation systems. It is specifically designed to address the communication needs between various devices in complex industrial environments, ensuring efficient and reliable information exchange.

In industrial automation setups, different devices such as PLCs, HMIs, sensors, and actuators often use different communication protocols, which can create barriers to seamless data flow. The UUD148AE01 effectively breaks down these barriers by supporting multiple communication protocols like Profibus DP and Modbus RTU. This allows it to connect diverse devices, enabling them to work in harmony. Whether in manufacturing plants, power stations, or water treatment facilities, the UUD148AE01 plays a crucial role in ensuring the smooth operation of the entire automation system by facilitating real-time data transmission.

Core advantages and technical highlights

Multi-protocol support: The UUD148AE01’s ability to support both Profibus DP and Modbus RTU eliminates the need for additional protocol converters. In an automobile manufacturing plant, it successfully connected a Profibus-based PLC with Modbus-enabled sensors, reducing the system complexity and saving equipment costs by 20%.

High data transfer rate: With a data transfer rate of up to 12Mbps, it ensures real-time data transmission. In a high-speed packaging line, the UUD148AE01 enabled the HMI to receive production data from the PLC instantly, allowing operators to adjust parameters in a timely manner and increasing production efficiency by 15%.

Strong anti-interference capability: Thanks to 2.5kV electrical isolation, it can work stably in environments with strong electromagnetic interference. In a steel mill with numerous high-power electrical equipment, the UUD148AE01 maintained reliable communication without data loss, ensuring the continuous operation of the rolling process.

Wide temperature adaptation: Its operating temperature range of -20°C to +60°C makes it suitable for use in extreme temperature environments. In an outdoor solar power station, where temperatures can vary greatly, the UUD148AE01 operated normally, ensuring the monitoring system could collect data from inverters and sensors without interruption.

Typical application scenarios

Automotive manufacturing: In an automotive assembly line, the UUD148AE01 connects the central PLC with robotic arms, conveyor belt sensors, and quality inspection devices. It transmits control signals from the PLC to the robotic arms and feeds back real-time data from sensors to the HMI. This ensures that each step of the assembly process is coordinated, reducing assembly errors by 25% and improving the overall production efficiency.

Water treatment plants: The UUD148AE01 is used to connect various water quality sensors, pump controllers, and the central control system. It transmits data such as pH value, turbidity, and flow rate from the sensors to the PLC, and sends control commands from the PLC to the pump controllers to adjust water flow and treatment processes. This enables precise control of the water treatment process, improving water quality compliance rate by 30%.

Food processing: In a food packaging plant, the UUD148AE01 connects the packaging machine controllers with temperature sensors, pressure sensors, and the production management system. It ensures that the packaging machines operate within the set temperature and pressure ranges by transmitting sensor data to the controllers. At the same time, it sends production data to the management system for production scheduling and quality tracking, reducing packaging defects by 18%.

ABB UUD148AE01

Related model recommendations

ABB HC800 HMI: When paired with the UUD148AE01, the HC800 can display real-time data transmitted by the module, allowing operators to monitor the system status intuitively and issue control commands.

ABB PLCs (e.g., PM861AK01): The UUD148AE01 acts as a communication extension for PLCs, enabling them to connect with more devices that use different protocols, expanding the control range of the PLC system.

ABB sensors (e.g., temperature, pressure sensors): These sensors can transmit data to the UUD148AE01, which then forwards the data to the control system, providing a reliable data source for the automation system.

ABB ACS880 drives: The UUD148AE01 can connect the ACS880 drives with the control system, enabling remote monitoring and control of motor speed and torque, optimizing the operation of the drive system.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the UUD148AE01, ensure the DIN rail in the control cabinet is clean and firm. Clip the module onto the DIN rail, ensuring a secure fit. Connect the 24V DC power supply using 0.75mm² shielded wires, making sure the positive and negative poles are correctly connected. For communication lines, use shielded twisted-pair cables (0.5mm²) for Profibus DP and Modbus RTU connections, and ensure proper grounding of the shields to reduce interference.

Maintenance suggestions: Inspect the module quarterly for loose connections or signs of damage. Clean the surface with a dry, soft cloth to remove dust. Check the power supply voltage regularly to ensure it is within the 24V DC ±10% range. Test the communication function monthly by using diagnostic software to verify data transmission between connected devices. If the module is installed in a high-temperature or high-humidity environment, enhance ventilation in the control cabinet to prevent overheating or moisture damage. Backup the module’s configuration data to a computer every six months.

Service and guarantee commitment

ABB provides a 2-year warranty for the UUD148AE01, covering manufacturing defects and performance issues under normal operating conditions. During the warranty period, ABB’s technical support team offers 24/7 assistance, including remote troubleshooting and guidance on installation and commissioning.

Customers can access detailed installation manuals, protocol configuration guides, and software tools through ABB’s official website. Optional services include on-site commissioning and training courses on module configuration and maintenance. ABB guarantees the availability of spare parts for 7 years after production, ensuring long-term reliable operation of the communication system.