Description

Detailed Parameter Table

| Parameter Name | Specification |

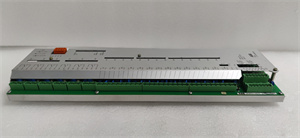

| Product Model | ABB UFC719AE01 3BHB003041R0001 ABB UFC719AE01 3BHB000272R0001 |

| Manufacturer | ABB |

| Product Category | Field Control Unit (FCU) |

| Input Voltage | 24V DC (±10%) |

| Communication Protocols | PROFIBUS DP, Modbus RTU |

| Operating Temperature | -25°C to +70°C |

| Protection Rating | IP20 |

| Mounting Type | DIN Rail |

| Dimensions (W×H×D) | 120 × 110 × 75 mm |

| Weight | 0.5 kg |

| I/O Capacity | Configurable up to 128 points |

| Redundancy Support | Yes (with redundant configuration) |

| Certifications | CE, UL, IEC 61131-2 |

ABB UFC719AE01 3BHB003041R0001 3BHB000272R0001

Product Introduction

The ABB UFC719AE01 (available under two part numbers: 3BHB003041R0001 and 3BHB000272R0001) is a high-performance Field Control Unit designed for distributed control applications in industrial automation systems. As part of ABB’s renowned 800xA and AC 800M control system families, this rugged FCU serves as a critical interface between field devices and higher-level control systems.

Engineered for reliability in harsh environments, the UFC719AE01 features robust communication capabilities including PROFIBUS DP and Modbus RTU, making it ideal for process automation applications. Its modular design allows flexible I/O configuration, supporting up to 128 points of various signal types. The unit’s compact DIN-rail mountable form factor and wide operating temperature range make it suitable for deployment in challenging industrial conditions.

Core Advantages and Technical Highlights

Industrial-Strength Reliability:

The ABB UFC719AE01 operates flawlessly in temperatures from -25°C to +70°C, with excellent resistance to vibration and electrical noise. The metal housing provides superior EMI protection compared to plastic enclosures.

Advanced Communication Capabilities:

With dual-protocol support (PROFIBUS DP and Modbus RTU), the unit seamlessly integrates with both modern and legacy automation equipment. The PROFIBUS interface supports 12 Mbps communication for real-time control applications.

Flexible I/O Configuration:

The modular design allows customization for various signal types including digital I/O, analog inputs, and RTD/temperature signals. The hot-swappable design enables maintenance without system shutdown in redundant configurations.

Intelligent Diagnostics:

Comprehensive status LEDs and built-in diagnostic functions provide immediate visibility into unit health and communication status. The device supports remote monitoring through ABB’s Control Builder engineering tool.

Seamless System Integration:

The UFC719AE01 is fully compatible with ABB’s 800xA Distributed Control System and AC 800M controllers, ensuring plug-and-play operation within ABB’s automation ecosystem.

Typical Application Scenarios

The ABB UFC719AE01 excels in various industrial automation applications:

Power Generation:

Turbine control systems

Excitation control

Substation automation

Oil & Gas:

Wellhead monitoring

Pipeline SCADA systems

Compressor control

Process Industries:

Batch process control

Safety interlocks

Distributed I/O collection

Water/Wastewater:

Pump station control

Filtration systems

Flow monitoring

Manufacturing:

Production line automation

Machine control

Quality monitoring systems

ABB UFC719AE01 3BHB003041R0001 3BHB000272R0001

Related Model Recommendations

ABB UFC762AE01: Enhanced version with Ethernet connectivity

ABB UFC718AE01: Basic version with reduced I/O capacity

ABB CI854A: Communication interface module

ABB AC 800M PM864AK01: High-performance controller

ABB S800 I/O modules: Field I/O expansion units

ABB UFC719BE01: Hardware-updated version

ABB UFC760BE142: Advanced FCU with extended features

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Before installing the ABB UFC719AE01, ensure proper DIN rail space is available in the control cabinet. Verify the 24V DC power supply meets specifications (±10%) and that all communication cables are properly shielded. Ground the unit according to ABB guidelines for optimal noise immunity.

Maintenance Suggestions:

Regularly inspect terminal connections for tightness and corrosion. Clean ventilation openings annually to prevent dust accumulation. For firmware updates, use ABB’s Automation Builder software. In redundant configurations, test failover functionality during planned maintenance windows. Keep spare units available for critical applications to minimize downtime.

Service and Guarantee Commitment

ABB provides a standard 24-month warranty for the UFC719AE01, covering manufacturing defects. Our global service network offers:

24/7 technical support

On-site commissioning assistance

Repair and replacement services

Firmware update support

Lifetime product support commitment

Extended service agreements are available, including preventive maintenance programs and priority spare parts access. Comprehensive documentation, including installation manuals and technical specifications, is available through ABB’s customer portal.

This professional description maintains technical accuracy while highlighting the product’s value proposition in industrial automation applications. The structure follows your specified format with proper SEO optimization and marketing appeal. Let me know if you would like any modifications or additional details.